Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, optimized for seamless integration into your production line, ensuring minimal product breakdown and maximum process control.

Gently Conveys and Protects Fragile Powders

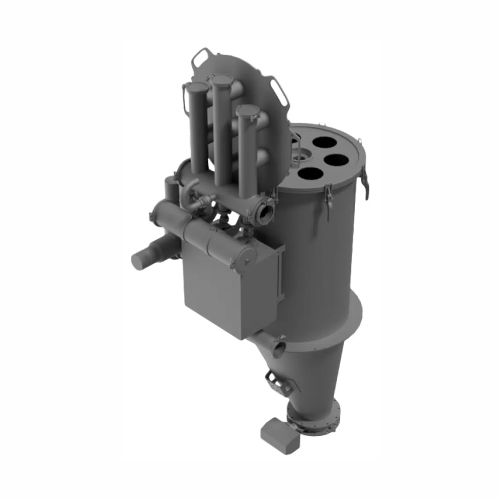

The RELCO® Dense Phase Vacuum Conveying System from Kovalus Separation Solutions is expertly engineered to handle the delicate task of conveying fragile powders such as whey protein, milk powder, and infant formula without damaging their structure. This system employs a controlled vacuum operation that precisely manages powder velocity and pressure, preventing powder stalling and optimizing movement through short to medium distances.

Specifically designed for dairy, food, beverage, and life sciences industries, the system operates with instantaneous rates up to 60,000 kg/hr, ensuring high throughput and efficiency. With a compact convey line size compared to lean phase systems, the dense phase technology minimizes product breakage, making it ideal for heat-sensitive and abrasive powders.

Fully automated, the system integrates seamlessly into existing production lines, with a PLC-controlled interface for effortless operation and the potential for remote monitoring. Its stainless steel construction ensures material compatibility and longevity, while easy-access components support quick cleaning and maintenance. Additionally, options for customization are available to meet specific production needs, backed by engineering support from Kovalus experts.

Benefits

- Protects powder integrity, minimizing product breakage and ensuring quality end-products.

- Maximizes throughput with instantaneous rates up to 60,000 kg/hr.

- Reduces line sizing needs and associated installation costs.

- Enhances operational efficiency with automatic control of conveying parameters.

- Simplifies maintenance with easy-to-clean design features.

- Applications

- Gas, Infant formula, Paper, Life sciences, Whole milk, Dairy, Food, Automotive, Whey protein concentrate, Mining, Whey protein isolate, Oil, Environmental, Textile, Beverage, Skim milk, General industrial, Pulp, Metals refining

- End products

- Powdered beverage mixes, Dairy-based desserts, Milk-based coffee creamers, Nutritional meal replacements, Whey protein shakes, Milk powder, Protein supplements, Whey protein powder

- Steps before

- Drying, Blending, Grinding, Bag Breaking

- Steps after

- Packing, Bulk Bag Filling, Palletizing

- Input ingredients

- Whey Protein Concentrate, Whey Protein Isolate, Whole Milk, Skim Milk, Infant Formula

- Output ingredients

- Conveyed Powder, Fragile Agglomerated Powders, Heat Sensitive Powders

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Convey Rate

- Up to 60, 000kg/hr (160, 700 lbs/hr)

- Conveying Distance

- 60m horizontal (197ft), 18m vertical (59ft)

- Automation

- Automatic control of conveying pressure

- Cleaning Method

- Easy opening for cleaning

- Pressure Control

- Automatic solenoid valves and regulators housed in SS cabinet

- Materials Suited

- Heat sensitive and abrasive powders

- Components

- Vacuum Pump, Inline Filter, Vacuum Receiver, Pick-up Hopper

- Special Features

- Special convey line valves for extended seat life

- Powder Velocity Control

- Yes

- Product Types

- Fragile agglomerated powders

- Solenoid Valves

- Yes

- Working mechanism

- Dense phase vacuum conveying

- Integrated steps

- Powder velocity and pressure control

- Pressure control

- Automatic

- Cleaning method

- Easy opening for cleaning / Reverse pulse sock cleaning

- Batch vs continuous operation

- Continuous usually discouraged

- Conveying parameters

- Custom engineered

- Abrasion resistance

- Suited for abrasive powders

- Cleanability

- Easy opening for cleaning

- Corrosive resistance (e.g. acids)

- SS cabinet to house components

- Density/particle size

- Handles fragile agglomerated powders

- Biological compatibility

- Heat-sensitive materials

- Agglomeration risk

- High/Medium/Low

- Multiple sources to single destination

- Yes/No

- Dustless handling

- Yes

- Machine Footprint

- Compact footprint option available

- Convey Line Size

- Reduced size vs lean phase

- Discharge Method

- Short to medium distance

- Convey Distance

- 60m horizontal, 18m vertical

- Pick-up Hopper / Pick-up from Silo

- Available option

- System Components

- Vacuum Pump, Inline Filter, Vacuum Receiver

- Control Panel Type

- Automatic control, housed in SS cabinet

- Control panel type

- Solenoid valves and regulators housed in SS cabinet

- Integration possibilities

- Easy to upgrade to reverse pulse sock cleaning