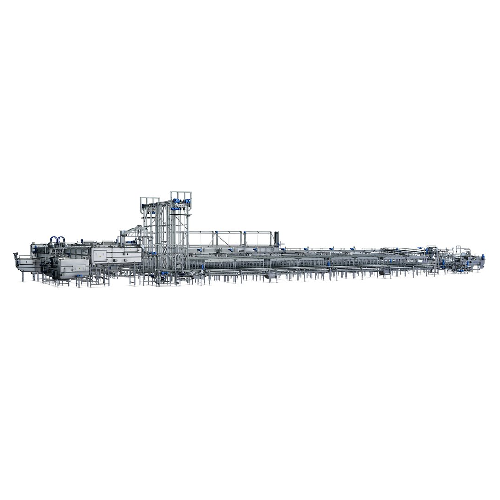

Whey tray system for cheese pressing

Optimize cheese production with an innovative system that efficiently presses semi-hard and hard cheeses while capturing high-quality whey, ensuring gentler handling, reduced waste, and seamless integration into high-capacity lines.

Presses and Forms Semi-Hard and Hard Cheeses

The Tetra Pak® Whey Tray System offers an optimized solution for cheese manufacturers seeking to improve pressing and forming processes for semi-hard and hard cheeses. This system specializes in using whey trays to collect high-quality whey, ensuring maximum profitability during production. By featuring continuous pressing with a capacity of 50-150 tons of cheese per day, it supports high-throughput operations for products like Gouda, Edam, and Parmesan. Integrated into production lines, it minimizes energy use and waste by reducing cycle speeds and wear. The Whey Tray System’s adaptable layout fits various plant capacities and cheese formats while facilitating easy maintenance through open presses and low CIP requirements. A triple-level rinsing unit ensures effective cleaning of moulds, lids, and trays, enhancing operational efficiency. Tailored to meet specific industry needs, this system stands out for its sustainable design and robust performance in dairy and cheese production.

Benefits

- Enhances whey quality and yield, maximizing profitability and minimizing waste.

- Reduces operational costs with low cycle speeds and limited cleaning requirements.

- Increases production flexibility with customizable system layout for varied cheese types.

- Ensures efficient cleaning and maintenance with a triple-level rinsing unit.

- Supports sustainable production by minimizing chemical and energy use.

- Applications

- Hard cheese, Cheese, Whey production, Semi-hard cheese

- End products

- Emmental cheese, Jarlsberg cheese, Parmesan cheese, Maasdam cheese, Ricotta cheese, Whey butter, Edam cheese, Gouda cheese, Whey protein

- Steps before

- Curd Preparation, Mould and Lid Handling

- Steps after

- Whey Collection, Cleaning, Maintenance

- Input ingredients

- semi-hard cheese, hard cheese, cheese curd

- Output ingredients

- high-quality whey, formed cheese, pressed cheese

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 50–150 tons of cheese per day

- Automation

- Limited CIP requirements

- Cycle speed

- Reduced cycle speed of line

- Rinsing unit

- Triple level rinsing unit

- Adaptable layout

- Yes

- Working mechanism

- Continuous pressing and forming

- Integrated steps

- Pressing, forming, mould and lid handling

- CIP/SIP

- Limited CIP requirements

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Triple level rinsing unit

- Automation level

- Manual / PLC / SCADA

- Adaptable layout

- Customizable to fit plant specifications

- Energy efficiency

- Minimized energy usage

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tray system layout

- Adaptable to plant requirements

- Control panel type

- Easy access, open presses

- Rinsing machine design

- Compact, triple level

- Pressing tray size

- Accommodates multiple moulds

- Discharge method

- Tray emptying and cleaning

- Cycle speed

- Low cycle speed for gentler processing