Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and streamline bag handling in your production line using a robust, customizable bulk bag unloader designed for challenging materials.

Efficiently Unloads and Transfers Bulk Powders

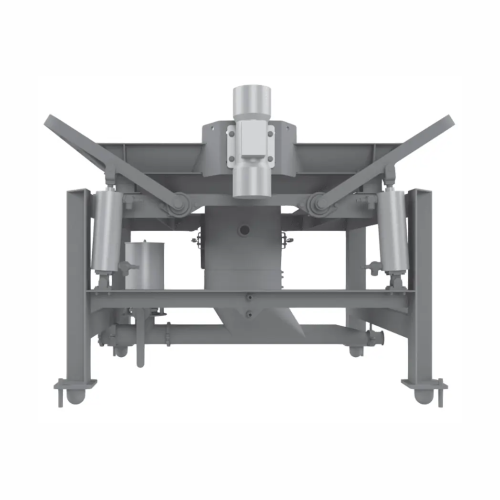

The RELCO® Bulk Bag Unloader from Kovalus Separation Solutions stands out for its adaptable design tailored for USDA sanitary applications. It’s engineered to handle a wide range of powder materials, ensuring efficient unloading with minimal dust. The system incorporates a sanitary receptor tube with dual pneumatic cylinders for precise spout clamping, enhanced by a vibrating bag pan to promote consistent powder flow. Its robust construction supports a 2,500-pound capacity, accommodating various bag sizes. Suitable for industries like dairy, food, and beverage, it facilitates the handling of end-products like milk powder, whey protein, and baking mixes. Optional features such as a hoist and monorail system, dual-bag massagers, and loss-in-weight batching support integration into existing production lines. Constructed from stainless steel, it meets stringent sanitary requirements while ensuring easy cleaning and maintenance. This unloader not only improves throughput but also maintains operational efficiency with features like a dust collection port and manually-operated iris valve for controlled changeovers. Customization options and engineering support are available to meet unique processing needs across diverse industrial sectors.

Benefits

- Enhances production efficiency by ensuring consistent powder flow with minimal dust contamination.

- Increases operational versatility with customizable configurations for various bag sizes and materials.

- Reduces labor and changeover time with easy-to-use hoist and monorail system options.

- Supports high sanitary standards vital for food, dairy, and pharmaceutical industries.

- Minimizes material loss through robust spill control and dust management features.

- Applications

- Food, Sour gas, Environmental, Gas, Textile, Automotive, Beverage, Oil, Biogas, Metals refining, General industrial, Pulp, Mining, Paper, Life sciences, Dairy

- End products

- Baking mixes, Detergent powders, Infant formula, Pharmaceutical powders, Environmental remediation agents, Instant tea, Beverage powders, Textile dye powders, Automotive compound additives, Whey protein, Coffee creamer, Sugar substitutes, Milk powder, Pulp slurry additives, Pet food kibble, Fertilizer granules, Paper coating materials, Protein supplements, Industrial chemicals, Cement additives

- Steps before

- Drying, Blending, Gassing

- Steps after

- Packing, Powder Gassing

- Input ingredients

- bulk bags, powdered materials, difficult flowing materials

- Output ingredients

- unloaded powder, discharged bulk materials, less free-flowing products

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Capacity

- 2, 500 pounds

- Bag size compatibility

- Wide variety

- Vibration motor

- Tandem vibration isolators

- Automation

- Manual pneumatic cylinders

- Powder discharge method

- Vibrating bag pan and optional massagers

- Hoist type

- Motorized two-ton metric

- Hoist control

- Four-button pendant

- Modular Design

- Upper and lower frames can be oriented independently

- Automation Level

- Manual pneumatic cylinders

- Vibration Mechanism

- Stainless Steel Vibration Bag Pan with vibration motor

- Bag Massaging

- Dual-Bag Massagers operated via pneumatic air cylinders

- Changeover Facilitation

- Manually operated iris valve

- Dust Control

- Dust collection port within enclosure

- Hoisting System

- Optional Hoist and Monorail System

- Load Capacity

- 2, 500-pound

- Bag Size Compatibility

- Variety of bag sizes

- Biological compatibility

- Yes

- Cleanability

- USDA sanitary applications

- Corrosive resistance (e.g. acids)

- Stainless Steel Construction

- Density/particle size

- Variety of difficult, less free-flowing products

- Machine Footprint

- Compact, modular layout

- Frame Material

- Stainless Steel

- Frame Type

- Modular, stainless steel frame

- Machine Capacity

- 2, 500-pound

- Bag Size Compatibility

- Various sizes compatible

- Discharge Method

- Vibration pan and optional massagers

- Dust Control

- Enclosure with dust port

- Bag Clamp

- Dual manual pneumatic cylinders

- Spout Clamp Operation

- Manual pneumatic cylinders

- Spill Control

- 4-inch-high sideboards

- Hoist and Trolley

- Optional, motorized two-ton

- Vibration Isolation

- Tandem vibration isolators

- Iris Valve

- Manual operation for tie-offs

- Upper Module

- Optional for hoist/monorail

- Bag spout seal

- Dual-over-center latches

- Bag size compatibility

- Variety of sizes

- Vibration pan

- Stainless Steel mounted to tandem vibration isolators

- Bag massagers

- Dual-bag massagers with pneumatic cylinders

- Hoist and Monorail System

- Optional upper module

- Dust collection

- Integrated dust port

- Sanitary receptor tube

- Dual manually-operated, air-assisted cylinders

- Manual iris valve

- For partial bag tie-offs

- Bag lift adapter

- Optional stainless steel adapter

- Hoist module

- Single or dual with high-speed, low-profile motorized hoist and trolley system

- Loss-in-weight package

- Load cells, controls package and outlet shutoff valve

- Batching system

- Possible with volumetric feeder