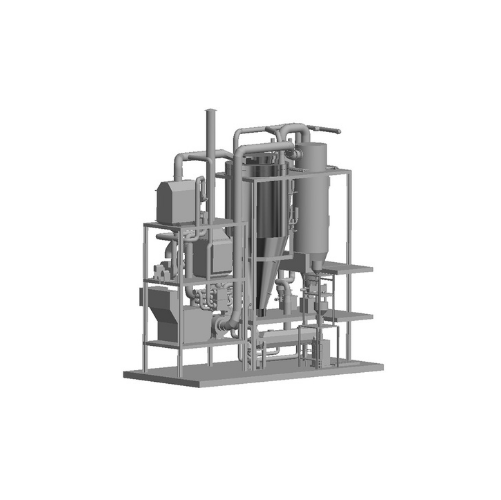

Spray drying system for heat sensitive products

For heat-sensitive products requiring precision drying, this spray drying system ensures consistent particle size and moisture control through efficient atomization and separation processes.

Transforms Liquids into Consistent Powders

The VetterTec Spray Dryer offers a comprehensive solution for transforming diverse liquid materials into uniform powders, serving industries from food to chemicals. Utilizing precision atomization, it efficiently dries heat-sensitive products, ensuring optimal particle size and moisture. Equipped with centrifugal and nozzle atomizers, it supports various drying needs. Integration options like fluid beds and agglomerators allow seamless production line incorporation. The VetterTec design accommodates both pilot and industrial-scale operations with continuous, automatic processing. Custom engineering and material selections are available, providing corrosion resistance and environmental compliance. A PLC-controlled system enhances efficiency, while CIP integration ensures maintenance ease.

Benefits

- Achieves precise powder consistency, enhancing product quality and performance.

- Minimizes energy usage with optimized thermal profiles, lowering operational costs.

- Customizable design allows seamless integration into existing production lines.

- Reduces contamination risks with CIP-ready systems, ensuring high hygiene standards.

- Facilitates broad application adaptability, increasing versatility across industries.

- Applications

- Soluble wheat proteins, Protein concentrates, Whey, Pigments, Maltodextrin, Polymers, Fruit powders, Wheat starch, Starch, Food supplements, Ceramics, Corn starch, Yeast, Brewery products, Vegetable proteins, Metal powders, Yeast extract, Modified starches, Herbicides

- End products

- Ceramic tile glaze, Glyphosate herbicide, Yeast culture powder, Pea protein isolate, Fruit juice powders, Powdered metal alloys, Vitamin supplements, Acrylic polymer powder, Collagen peptides, Wheat protein isolate, Yeast extract powder, Soy protein powder, Pregelatinized starch, Titanium dioxide pigment, Whey protein isolate, Maltodextrin powder, Gelatin hydrolysates, Corn syrup powder

- Steps before

- Emulsification, Homogenization, Wet feeding

- Steps after

- Agglomeration, Particle cooling, Packaging

- Input ingredients

- liquids, organic solvents, corn starch, wheat starch, maltodextrin, soluble wheat proteins, polyols, lysine, yeast, vegetable proteins, biochemical proteins, whey, protein concentrates, flavorings, soup mixes, fruit powders, herb extracts, glucose syrup, enzymes, fats, polymers, acryl, carbonates, carbides, ceramics, pigments, metal powders, silica, dyestuff, herbicides, tannins

- Output ingredients

- powder, dust-free powder, agglomerated powder

- Market info

- VetterTec is known for engineering and manufacturing industrial drying and dewatering solutions, particularly for the food, brewery, chemical, and environmental industries, leveraging extensive experience in delivering efficient and reliable tailored systems.

- Particle size range

- Small to large droplets

- Heating temperature

- 100°C to 750°C

- Drying method

- Atomizer / Hot air

- Drying integration

- Fluid beds / Agglomerators

- Atomization type

- Centrifugal wheels / Rotary / Pressure nozzles / Twin-fluid nozzles

- Control system

- Automatic

- Air separation method

- Cyclone / Filter system

- Flexibility of design

- High

- Working mechanism

- Atomization with centrifugal wheels, rotary atomizers, pressure nozzles, or twin-fluid nozzles

- Integrated steps

- Drying with fluid beds, cooling, agglomeration

- CIP/SIP method

- Cleaning in place (CIP)

- Batch vs. continuous operation

- Continuous operation

- Automation level

- Automatic control system

- Air incorporation control

- Controlled particle size and moisture content

- Energy efficiency

- High-efficient drying method

- Heating system

- Direct or indirect

- Environmental compliance

- Closed circuit and self-inertized

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Particle characteristics

- Controlled

- Specific particle properties

- Desired application

- Discharge method

- Cyclone and/or filter system

- Fluid bed configuration

- Internal/External

- Control panel type

- Automatic control system

- Control panel type

- Automatic control system

- Integration possibilities

- External fluid bed, cyclone, bag filter, homogenizer

- Heating system

- Direct or indirect heating systems

- Atomization type

- Centrifugal wheels, rotary atomizers, pressure nozzles, twin-fluid nozzles

- Particle size control

- Specific particle size requirements

- Dryer configuration

- Closed circuit and self-inertized dryers