Industrial fermentors for large-scale bioprocessing

Enhance yield and consistency in fermentation processes with precise control over cultivation conditions, enabling seamless scale-up from pilot to full industrial production.

Cultivates and Ferments Biotech and Pharmaceutical Products

The BRS-100/150/200SJ, BRS-250/300/500SJ, BRS-1000SJ, and BRS-3000SJ Industrial Fermentors and Bioreactors from BRS Biotech are engineered for seamless integration into biotech and pharmaceutical production lines. These systems cater to the cultivation and fermentation of a wide range of products, including monoclonal antibodies, insulin, and specialized enzymes like phytase. Constructed from 316 stainless steel, they ensure corrosion resistance and durability, meeting stringent GMP and FDA standards.

The fermentors and bioreactors operate with single or double-sealed magnetic bearings to guarantee robust mixing and minimal contamination. Available volumes range from 100 to 60,000 liters, allowing for customizable scaling from pilot to industrial production. These units feature comprehensive automation, including advanced remote control capabilities via a SCADA system. Mass flow control, automatic air flow metering, and integrated sensors for optical density, methanol, ethanol, and redox levels provide precise process control.

Designed for minimal downtime, these systems include Clean-In-Place (CIP) functionality for efficient cleaning and quick turnaround for subsequent batches. BRS Biotech offers customization options such as tailored agitation speed, temperature control, and pressure settings, ensuring each system aligns with specific production requirements. Suitable for liquid, gas, and slurry product types, they support both batch and continuous operations, making them ideal for diverse applications in the production of biopharmaceuticals, nutraceuticals, and other high-value biotech products.

Benefits

- Enhances production scalability with customizable volumes up to 60,000 liters.

- Improves process precision with advanced remote control and integrated sensor systems.

- Ensures rapid turnaround with Clean-In-Place functionality, minimizing contamination risks.

- Reduces energy costs through efficient mass flow control and optimized motor settings.

- Complies with GMP and FDA standards, ensuring reliable and safe pharmaceutical production.

- Applications

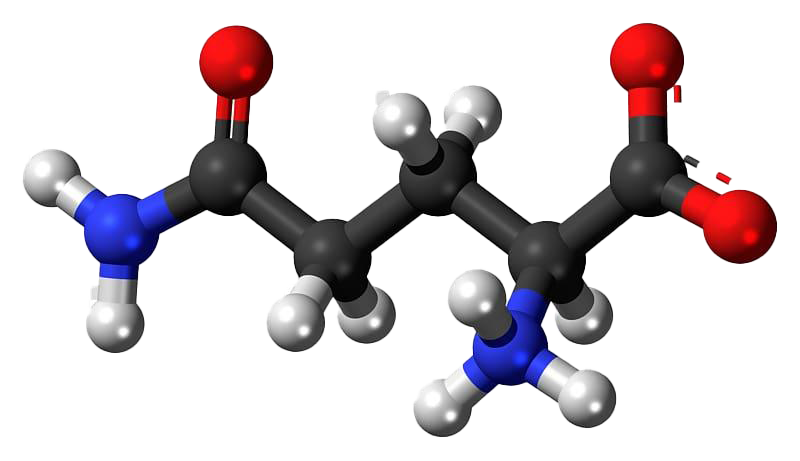

- Amino acids, Proteins, Vitamins, Supplements, Microbiological synthesis products, Nutraceuticals, Animal cells, Biopharmaceuticals, Enzymes, Food ingredients, Plant protection products, Pharmaceuticals

- End products

- Biopesticides, Xylanase enzyme, Insulin, E. coli recombinant proteins, Monoclonal antibodies, Probiotic capsules, Amino acid infusion solutions, Aspartic acid, Vitamin b12, Beta-glucanase enzyme, Alginate, Phytase enzyme, Glutamine supplement, Whey protein, Creatine supplement

- Steps before

- Cell culture preparation, Media preparation, Seed train, Inoculation

- Steps after

- Downstream processing, Purification, Concentration, Drying

- Input ingredients

- bacteria, yeast, fungi, animal cells, microorganisms, microalgae, macroalgae, substratum, medium, methanol, ethanol, acid, alkali, water, steam, air

- Output ingredients

- proteins, monoclonal antibodies (mAb), amino acids, enzymes, phytase, beta-gluconase, xylonase, probiotics, plant protection products

- Market info

- Available volumes

- 100/150/200/300/450/750/1000 l to 60, 000 l

- Material

- 316 Stainless Steel

- Agitation

- Single, double-sealed, or magnetic bearing

- Control functions

- Temperature, agitation speed, pH, DO, medium flow, antifoam/level, air flow (manual), pressure (manual)

- Advanced Controls

- MassFlowControl, air outlet filter heating, optical density sensor, cell suspension concentration monitoring sensor, methanol sensor, ethanol sensor, redox sensor, gas analyzer

- SIP ports

- For medium inlet system (acid, antifoam, alkali, substratum)

- SCADA

- Advanced remote control system

- Total Volume

- 100/150/200, 250/300/500, 1000, 3000 L

- Working Volume

- 70/120/160, 200/210/400, 700, 2100 L

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP 121°C / SIP 135°C

- Platform-mounted design

- Open frame construction

- Central connection system

- Steam, water, and air

- Cell cultivation support

- Bacteria, yeast, fungi, animal cells

- Access level

- Easy access for maintenance and operation

- Photobioreactor capability

- Aquatic organisms, micro– and macroalgae

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- High

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Adjustable depending on application

- Material

- 316 Stainless Steel

- Total Volume

- 100 L - 60, 000 L

- Working Volume

- 70 L - 2100 L

- Construction Type

- Open frame, platform-mounted

- Agitation

- Single, double-sealed or magnetic bearing

- Available Volumes

- 100/150/200/300/450/750/1000 L and more

- Control panel type

- SCADA advance – advanced remote control system

- Integration possibilities

- Stand-alone or fully equipped lines for biotech and pharmaceutical plants

- Agitation system

- Single, double-sealed, or magnetic bearing

- Volume range

- 100L to 60, 000L and more

- Frame construction

- Open frame for easy maintenance and operation

- Customization setup

- Custom setup via questionnaire

- Basic control functions

- Temperature, agitation speed, pH, DO, medium flow, antifoam/level, air flow (manual), pressure (manual)

- Advanced control functions

- MassFlowControl, automatic air flow meter, optical density sensor, cell suspension concentration monitoring sensor

- Sensor options

- Methanol, ethanol, redox sensors

- Material

- 316 Stainless Steel

- Platform-mounted

- Yes

- Central connections

- Steam, water, and air