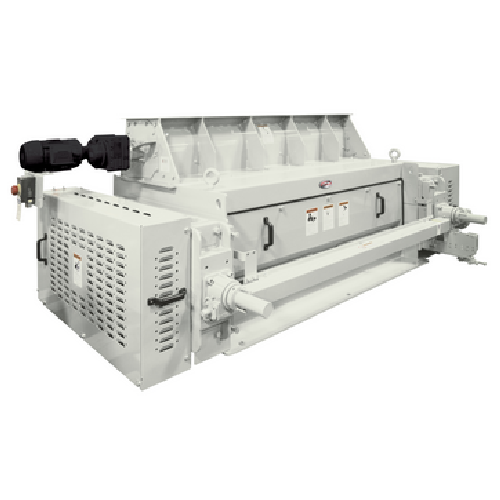

High-capacity pellet crumbler

Achieve precise pellet size reduction with this high-capacity solution, designed for effortless integration into continuous production lines, enhancing efficiency and product consistency across various applications.

Reduces Pellet Size for Efficient Processing

The CMX/R Series from CPM offers an innovative solution for reducing pellet sizes in high-capacity production environments. Designed for versatility, this crumbler handles a wide range of applications, including animal feed, biomass, and aquaculture industries. Its compact design is perfect for continuous operations, ensuring seamless integration into existing production lines. With a robust bearing support system that allows for roll separation forces and easy-access rolls, the CMX/R Series optimizes crushing efficiency. Optional features such as manual or air-actuated roll adjusting further enhance its adaptability and operational precision. Offering reliable performance, it operates at high efficiencies and can handle substantial throughput, making it ideal for producing end-products like animal feed pellets, wood pellets, and hemp pellets. Customizable options and superior engineering support ensure the CMX/R Series meets your specific production requirements.

Benefits

- Enhances production efficiency with high-capacity size reduction.

- Reduces operational downtime with easy-access rolls and quick adjustments.

- Integrates seamlessly into existing production lines for consistent performance.

- Offers flexibility with customizable roll adjustment options for precise control.

- Ensures reliable granule quality for diverse end-products like animal feed and biomass pellets.

- Applications

- Aquaculture, Animal feed, Ethanol, Pet food, Hemp, Food industry, Oilseed processing, Rendering, Biomass

- End products

- Cereal flakes, Hemp pellets, Pet kibble, Wood pellets, Meat and bone meal, Fish feed pellets, Animal feed pellets, Soybean meal, Ethanol feedstock

- Steps before

- Pelleting, Cooling

- Steps after

- Weighing, Packing

- Input ingredients

- pellets

- Output ingredients

- crumbled pellets

- Market info

- CPM is known for manufacturing high-quality process equipment and technology solutions for the industrial and agricultural sectors, specializing in particle size reduction, conditioning, and pelleting solutions with a strong reputation for reliability and innovation.

- Capacity

- High-capacity

- Efficiency

- High-efficiency

- Ease of Operation

- Easy Access to Rolls

- Automation

- Manual handwheel, air-actuated, two-position or full-feature roll adjusting options

- Construction Quality

- High-quality Construction

- Bearing Support System

- For Roll Separation Forces

- Inspection Access

- Easy Access to Rolls for Inspection

- Roll separation force

- Adjustable

- Ease of operation

- Easy access to rolls

- Roll adjusting options

- Manual handwheel / Air-actuated

- Compact installation

- Space-saving design

- Capacity

- High-capacity

- Efficiency

- High-efficiency

- Automation level

- Optional

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Compact installation

- Discharge method

- Roll feeder

- Control panel type

- Manual handwheel, air-actuated

- Roll adjusting options

- Manual handwheel, air-actuated, two-position or full-feature

- Feeder type

- Roll feeder, Pocket feeder

- Surge panels

- Available