Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation that enhances efficiency, ensures precise batch consistency, and enables comprehensive tracking and tracing capabilities for high-quality output.

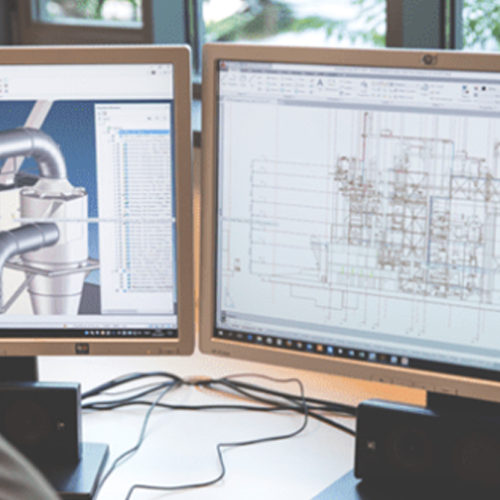

Automates Batch Mixing and Production Control

Inteqnion’s Batch Explorer, integrated seamlessly with Ottevanger Milling Engineers, revolutionizes batch processing by automating critical stages like intake, batching, grinding, and mixing. Designed for feed, grain, and soybean industries, it supports the production of pelletized feeds, soy products, and oilseeds. Utilizing a PLC-engineered system with SCADA visualization, the Batch Explorer facilitates MES integration and industrial networking. This ensures streamlined operations and real-time monitoring for up to 50 tons per hour. Its modular structure allows for customization to meet specific plant requirements, while leveraging a Microsoft SQL database for robust performance. The system is built to support contamination tracking, vital for maintaining product integrity and complies with industry standards for safety and quality. Available with various material options to withstand demanding environments, this automation system provides engineering support for tailored configurations, maximizing plant efficiency and resource management.

Benefits

- Enhances operational efficiency by automating critical batch processes.

- Provides real-time data insights with SCADA integration, improving decision-making.

- Reduces production errors with precise MES-supported controls.

- Customizable setup ensures seamless integration with existing systems.

- Supports production traceability, maintaining high-quality standards and compliance.

- Applications

- Handling, Pet food, Oilseed processing, Soybean processing, Aqua feed, Concentrates, Premix, Grain storage, Compound feed

- End products

- Dog kibble, Grain handling equipment, Pelletized livestock feed, Soy flour, Vitamin and mineral premix, Protein concentrates, Fish pellets, Compound feed additives, Cat biscuits, Soy protein isolate, Grain storage bins, Cold-pressed oilseeds, Soybean oil

- Steps before

- Product intake, Batch Weighing, Pre-cleaning, Micro-ingredient dosing

- Steps after

- Mixing, Pelleting, Coating, Bulk out loading

- Input ingredients

- feed materials, flour, bulk ingredients, raw materials

- Output ingredients

- processed feed, flour products, bulk out loading, final product

- Market info

- Ottevanger Milling Engineers is renowned for designing and manufacturing innovative milling equipment and complete production lines for the grain processing industry, including feed mills, flour mills, and biomass processing, with a reputation for quality, efficiency, and customized solutions.

- Automation

- PLC-controlled

- SCADA visualisation

- Siemens WinCC package

- MES integration

- Yes

- Software Database

- Microsoft SQL

- Batch size

- Small and big plants

- Process Control

- Intake, batching, grinding, mixing, pelleting, coating, bulk out loading

- Industrial Networks

- Profibus, Profinet, ASI, Ethernet

- Modular program structure

- Yes

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Industrial Networks

- Profibus / Profinet / ASI / Ethernet

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- SCADA touch panel

- Discharge method

- Batch, continuous

- Control panel type

- SCADA touch panel

- Integration possibilities

- PLC engineering, programming, MES integration, Industrial Networks

- Modular software

- Yes, built as modular program

- Open software structure

- Yes, easy to adjust to customer requirements

- Database compatibility

- Microsoft SQL database

- Visual display package

- Siemens WinCC SCADA