Compound feed

Find innovative production technology for making compound feed and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in compound feed making

Which compound feed technology do you need?

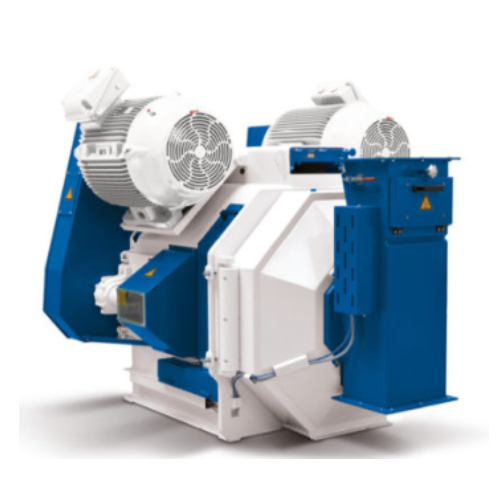

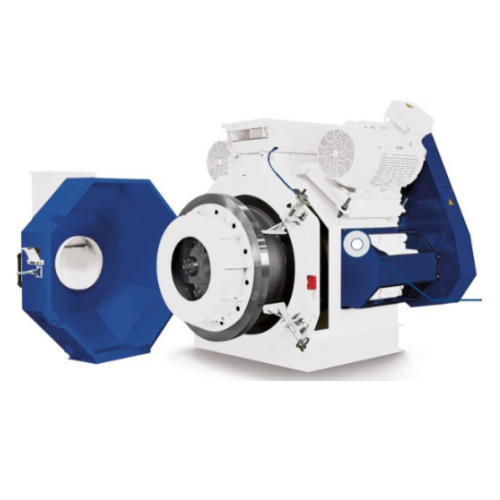

Pellet mill for high efficiency animal feed production

Achieve stable, vibration-free pellet production with enhanced ene...

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

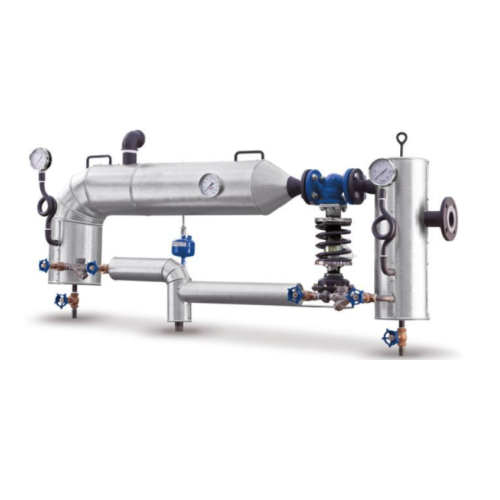

Steam injection systems for animal feed production

Enhance product quality in animal feed production with steam injection...

Cryloc rotary screens for grain processing

Efficiently sort and separate fine particles with high precision to enhance pro...

Industrial vibrating sieves for pellets and fine particles

Optimize feed quality and material flow in your production li...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

Cylindrical storage silos for long-term raw material storage

Efficiently store bulk raw materials for extended periods w...

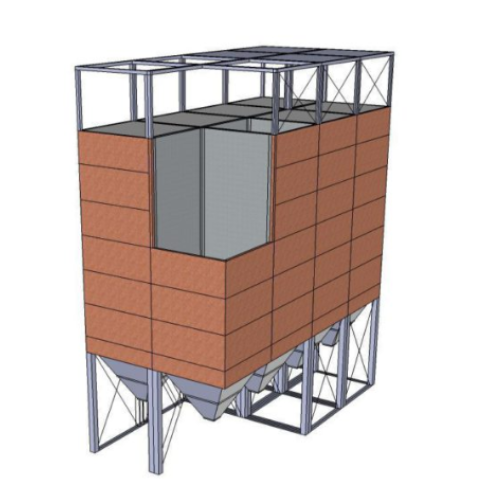

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

Hammer mills for high-efficiency grinding in feed production

Optimize your feed production with high-efficiency grinding...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

High efficiency roller mill for grain and oilseeds

Optimize your crushing and grinding processes with a versatile roller ...

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

Horizontal ribbon mixers for animal feed production

Experience precise and efficient mixing with low energy consumption f...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your productio...

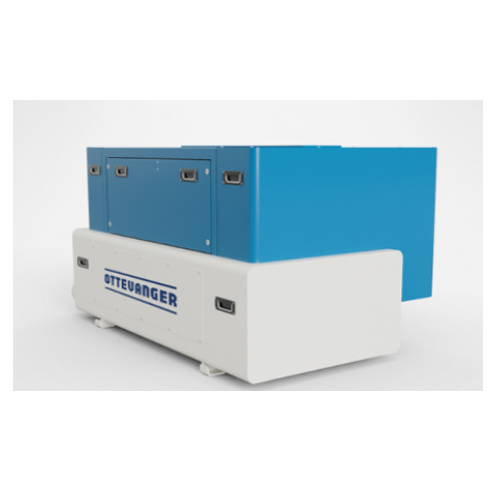

Counterflow pellet coolers

Optimize temperature control and enhance product integrity in your feed production line with prec...

Counterflow dryer for pet food and fish feed

Optimize moisture control and enhance feed quality with efficient drying, cru...

Industrial control panel construction

Streamline your production line with advanced panel building solutions that enhance a...

Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation ...

Industrial hammer mill for granulate grinding

Optimize the grinding process in feed production with a high-efficiency solu...

Hammer mill for efficient particle size reduction in feed mills

Optimize your feed milling operations with this hammer m...

Feed expander for improved pellet mill output

Enhance your feed quality and production efficiency with a robust expander d...

Hot start conditioner for feed and food processing

Enhance your production process with a high-efficiency thermal heating...

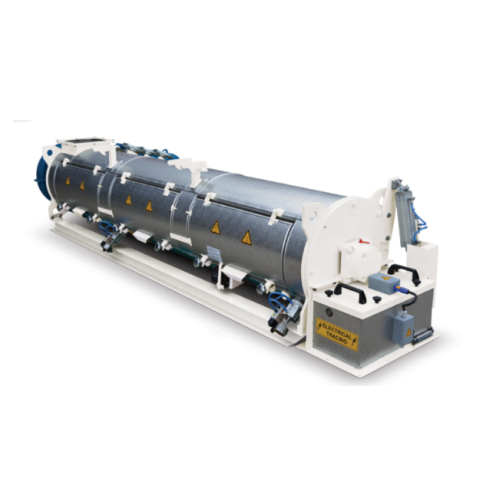

Retention time barrel for feed pelleting

Enhance your feed processing efficiency with a specialized retention time barrel, ...

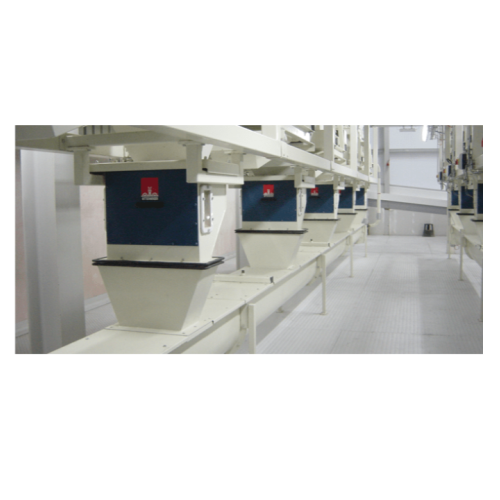

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

Rotary dischargers for powders and granules

Prevent production halts with this solution designed for efficient discharge o...

Screw conveyors for grain processing and feed mills

Optimize your production line with versatile screw conveyors, designe...

Feed pellet crumbler

Achieve precise size reduction of feed pellets with high efficiency and minimal fines, optimizing your p...

Batch weighers for large-volume powder and granulate weighing

Ensure precise ingredient dosing and streamline your produ...

Industrial pre-cleaners for raw material safeguarding

Effectively eliminate foreign objects from your raw materials with ...

Continuous coater for pellet and extrudate liquid addition

Efficiently enhance your feed products by uniformly adding li...

Feed mill compactor for improved pellet quality

Optimize your feed production with a compactor designed to enhance pellet ...

Single conditioner for feed mills

Achieve homogeneous mixing and enhanced hygiene in feed production with adjustable paddle...

Vertical transport for bulk goods

Efficiently move bulk goods vertically with minimal energy usage, ensuring seamless integ...

Trough screw conveyor for grain transport

Streamline your grain processing with a reliable conveyor system that ensures ef...

Trough screw conveyor for transporting grains

Efficiently transport and handle bulk materials like grains and flour with r...

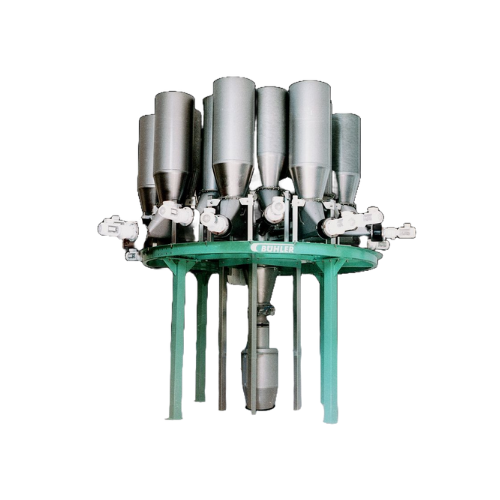

Micro-dosing system for animal feed additives

Achieve precise and consistent feed formulation with high-precision micro-do...