Steam injection systems for animal feed production

Enhance product quality in animal feed production with steam injection systems that boost compressibility and inactivate microbes, all while preserving the sensory properties of your feed mix.

Injects Steam for Heating and Conditioning

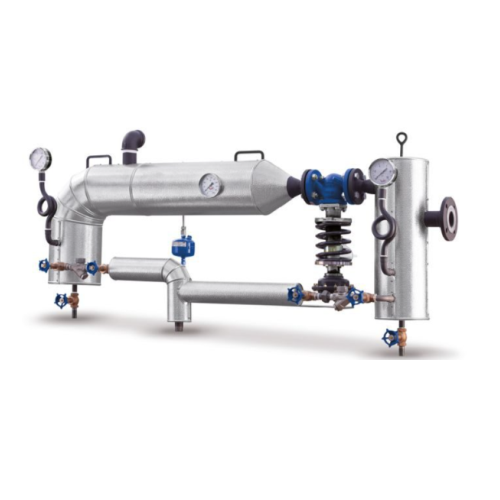

Ottevanger Milling Engineers’ Steam Injection System delivers precise heating and conditioning in feed mill operations by injecting high-quality dry steam into your process. This enhances the compressibility and safety of animal feeds, meeting stringent production standards. The system efficiently processes feeds for pets, aquaculture, and livestock, supporting applications in soymeal and oil production as well.

Available with capacities ranging from 150 to 2,500 kg/hr, the system ensures continuous, high-speed operation suitable for large-scale productions. Its design features an energy-efficient steam line with an integrated steam flash generating superheated steam, reducing boiler energy consumption and promoting heat transfer efficiency.

The compact steam sets integrate seamlessly with upstream feeding systems and downstream pelleting or extrusion equipment, facilitating automatic operation through PLC controls. Constructed with durable materials, it resists corrosion in challenging environments, ensuring longevity and reliability. Moreover, it supports easy installation and maintenance, minimizing downtime while maximizing productivity. Adaptable configurations and engineering support ensure the Steam Injection System can meet specific process requirements, bolstering your feed production’s efficacy and quality.

Benefits

- Increases production efficiency by enhancing feed compressibility and quality.

- Reduces energy costs with optimized steam usage and minimal boiler dependency.

- Ensures microbial safety, maintaining feed hygiene without compromising nutrients.

- Seamlessly integrates with existing production lines for automated, continuous operation.

- Offers flexible capacity options to cater to varying production demands.

- Applications

- Pet food, Oilseed processing, Soybean processing, Aqua feed, Concentrates, Premix, Compound feed

- End products

- Broiler chicken feed pellets, Full-fat soymeal, Soybean cake, Kibble for dogs and cats, Mineral premix, Fish pellets, Layer mash, Soybean oil, Vitamin premix

- Steps before

- Grinding, Mixing

- Steps after

- Conditioning, Pelleting

- Input ingredients

- animal feed ingredients, laying mash, product mix

- Output ingredients

- high-quality (dry) steam, superheated dry steam, conditioned animal feed

- Market info

- Ottevanger Milling Engineers is renowned for designing and manufacturing innovative milling equipment and complete production lines for the grain processing industry, including feed mills, flour mills, and biomass processing, with a reputation for quality, efficiency, and customized solutions.

- Capacity

- 150–2, 500 kg/hr

- Steam Temperature

- up to approx. 140° C

- Energy Efficiency

- Low energy use

- Installation Ease

- Easy to install

- Steam quality

- Dry, High-temperature

- Steam capacity

- 150 – 2, 500 kg/hr

- Temperature control

- Up to 140°C

- Energy efficiency

- Energy savings with steam boiler

- Operation ease

- Easy to install

- Microbial inactivation

- Yes

- Installation type

- Compact systems

- Integration with production process

- Feeding, Mixing, Pressing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Microbial inactivation

- Yes

- Product integrity

- Retained sensory properties

- Control panel type

- PLC-controlled

- Integration possibilities

- Steam lines and injection systems on mixers, presses, expanders, and compactors

- Volume-increasing drainage vessel

- Steam flash generation

- Compact system capacity options

- 150 – 2, 500 kg/hr