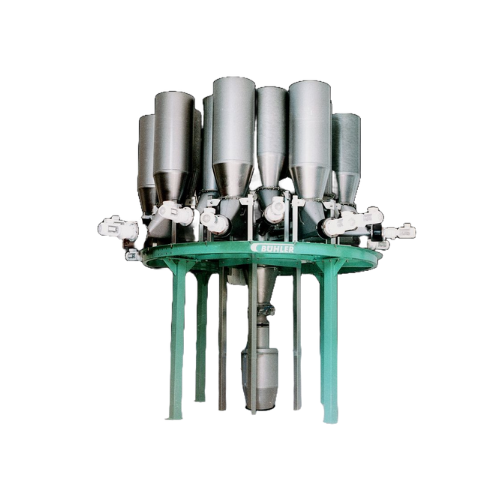

Micro-dosing system for animal feed additives

Achieve precise and consistent feed formulation with high-precision micro-dosing, ensuring accurate proportioning of trace elements and additives, crucial for optimal animal nutrition and feed quality.

Precisely Doses and Weighs Feed Ingredients

The Bühler Group’s Micro-Dosing System is engineered for precision in proportioning critical feed ingredients like vitamins and trace elements. This system features a sophisticated weighing mechanism, achieving an accuracy of 0.1% of scale capacity, ensuring reliable formulations for animal, aqua feed, and pet food production. Designed with automation in mind, it seamlessly integrates into existing production lines, allowing for automatic proportioning of up to 20 ingredients and quick adaptation to different batch recipes. Its stainless steel construction ensures superior sanitation and durability, minimizing contamination risks and supporting safe operations. This system is ideal for processing powders and granules, with applications spanning the production of cattle feed, poultry feed, fish pellets, and more. Capable of continuous operation, it enhances production efficiency and quality assurance, making it indispensable for feed producers and manufacturers.

Benefits

- Enhances ingredient precision, ensuring consistent feed quality and nutritional value.

- Minimizes contamination risk with fully stainless steel construction and dust-free bin-filling.

- Reduces manual handling errors through automated ingredient proportioning.

- Supports rapid recipe changes, speeding up production transitions and increasing operational flexibility.

- Maintains high processing accuracy, boosting confidence in formulation integrity.

- Applications

- Vitamins, Animal feed, Pet food, Premixes, Additives, Aqua feed, Trace elements, Compound feed

- End products

- Iron supplements, Shrimp diet granules, Mineral premix, Enzyme additives, Kibble, Amino acid additives, Zinc supplements, Probiotics supplements, Fish pellets, Poultry feed, Cattle feed, Vitamin premix

- Steps before

- Weighing, Blending, Mixing, Raw material handling

- Steps after

- Packing, Palletizing, Optical sorting, Quality control

- Input ingredients

- vitamins, additives, trace elements, micro-components, raw material, compound feed materials

- Output ingredients

- premixes, compound feed, aqua feed, pet food, concentrates

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Accuracy

- 0.1% of scale capacity

- Dosing type

- Automatic proportioning

- Number of components managed

- Up to 20

- Contact materials

- Stainless and electro-polished steel

- Contamination risk minimization

- Complete bin discharge

- Automation level

- Automated processes

- Automation level

- Automated

- Batch vs. continuous operation

- Batch

- Changeover time

- Fast adaptation

- Cleaning method

- Dust-free bin-filling

- Energy efficiency

- High precision

- Safe design

- Minimized contamination risk

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Stainless Steel

- Density/particle size

- Varied

- Abrasion resistance

- Electro-polished steel

- Material

- Stainless and electro-polished steel

- Discharge method

- Complete bin discharge

- Dust control

- Dust-free bin-filling unit

- Maximum number of micro-components

- Up to 20

- Component particle size

- Coarse or fine

- Control panel type

- Touch screen / PLC

- Integration possibilities

- SCADA / ERP systems

- Material of construction

- Stainless steel / Electro-polished steel

- Automation level

- Manual / Automatic