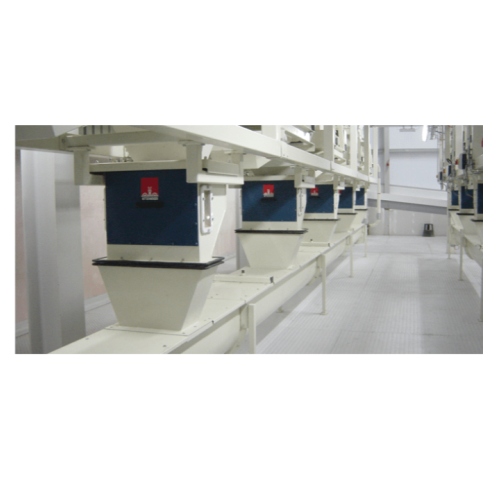

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your production line with advanced weighing systems that ensure consistent product flow, enabling seamless integration and optimal dosing accuracy for varied materials.

Accurately Weighs and Doses Powders and Granules

Ottevanger Milling Engineers offers robust Inline and Continuous Weighing Systems, ideal for precise weighing and dosing of powders and granules in various industrial applications. These systems work seamlessly in feed manufacturing and processing lines by interfacing with existing equipment such as screw feeders or vibrating chutes to maintain constant product flow. Suited for operations ranging from pet food to grain processing, the equipment handles up to 90 m³ per hour, ensuring accurate and stable product measurements. The design prioritizes purity of materials and minimal residue build-up, offering easy integration into your automation systems with options for PLC control. Constructed from high-quality materials for durability and featuring a straightforward maintenance design, these systems are configurable to meet specific processing needs, providing dependable performance across complex industrial environments.

Benefits

- Enhances operational efficiency by ensuring consistent and precise dosing and weighing.

- Reduces material waste and improves product quality through accurate flow control.

- Integrates seamlessly into existing production lines, minimizing setup and transition times.

- Lowers maintenance needs with a design focused on material purity and minimal fabric remnants.

- Offers flexible processing capacity, adapting to varied production requirements with adjustable dosing speeds.

- Applications

- Handling, Pet food, Oilseed processing, Soybean processing, Aqua feed, Concentrates, Premix, Grain storage, Compound feed

- End products

- Refined soybean oil, Bulk wheat storage, Processed soybean meal, Extruded fish feed, Protein concentrates, Vitamin and mineral premixes, Dry cat food kibbles, Pelletized animal feed, Corn grain handling

- Steps before

- Product intake, Storage, Conveying, Grinding

- Steps after

- Packing, Coating

- Input ingredients

- powdered form, granulated form, product flow, one component

- Output ingredients

- weighed product, constant product flow, accurately weighed material

- Market info

- Ottevanger Milling Engineers is renowned for designing and manufacturing innovative milling equipment and complete production lines for the grain processing industry, including feed mills, flour mills, and biomass processing, with a reputation for quality, efficiency, and customized solutions.

- Capacity

- Up to 90 m³/hour

- Process Type

- Continuous

- Accuracy

- High accuracy, exact value not specified

- Working mechanism

- Continuous process

- Integrated steps

- Inline weighing and dosing

- Batch vs. continuous operation

- Inline Continuous

- Capacity control

- Variable dosing speed

- Product form compatibility

- Powdered or granulated

- Silo outlet placement

- Underneath

- Machine footprint

- Compact design

- Capacity

- Up to 90 m³/hour

- Material purity

- Ensures high purity levels

- Weigher design

- Ensures high stability and accuracy

- Discharge method

- Inline continuous flow

- Control panel type

- HMI / Touchscreen / PLC

- Integration possibilities

- SCADA / ERP systems

- Capacity modification

- Adjustable dosing speed

- Installation placement

- Under silo outlet

- Material compatibility options

- Powder / Granulated form