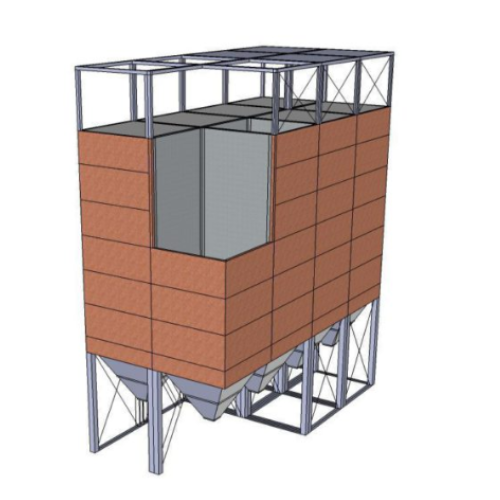

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effective discharge and optimal space utilization, eliminating challenges with difficult bulk products.

Maximizes Storage Capacity and Ensures Efficient Discharge

The Square Silo by Ottevanger Milling Engineers offers an innovative storage solution, maximizing capacity by 25% over round silos. Its unique design features ultra-smooth flat walls, facilitating seamless discharge of granular and solid products. Modular assembly allows flexible configuration tailored to specific needs, with robust steel construction ensuring safety and compliance with European standards. Ideal for industries like compound feed, pet food, and recycling, the Square Silo integrates easily into continuous and automated production lines. It supports a range of materials, including chemicals and grains, enabling you to optimize space while maintaining a hygienic environment.

Benefits

- Increases storage capacity by 25%, optimizing space usage.

- Ensures smooth product discharge, minimizing handling time and waste.

- Modular design allows for custom configurations to meet specific production needs.

- Meets European safety standards, ensuring regulatory compliance and safety.

- Reduces operational costs with efficient automated processes.

- Applications

- Flour plants, Grains, Chemicals, Pet food, Coffee roasting, Compound feed, Rice, Aqua feed, Seeds, Recycling products, Premix, Breweries

- End products

- Craft beer malt, Polyethylene granules, Dog kibble, Wheat flour, Fish pellets, Poultry feed, Recycled plastic pellets, Parboiled rice, Sunflower seeds, Ground coffee, Vitamin premix

- Steps before

- Pre-cleaning, Product intake, Dosing, Weighing, Grinding

- Steps after

- Mixing, Conditioning, Pelleting, Coating, Packing

- Input ingredients

- bulk goods, dry and granular bulk goods, compound feed materials, pet food ingredients, aqua feed materials, premix components, breweries ingredients, grains, seeds, flour, coffee beans, rice, chemicals, recycling products

- Output ingredients

- stored bulk goods, processed dry and granular bulk goods, stored compound feed materials, stored pet food ingredients, stored aqua feed materials, stored premix components, stored brewery ingredients, stored grains, stored seeds, stored flour, stored coffee beans, stored rice, stored chemicals, stored recycling products

- Market info

- Ottevanger Milling Engineers is renowned for designing and manufacturing innovative milling equipment and complete production lines for the grain processing industry, including feed mills, flour mills, and biomass processing, with a reputation for quality, efficiency, and customized solutions.

- Storage Capacity

- 25% more than round silos

- Cell Sizes

- Various sizes available

- Material

- Steel components

- Modular Assembly

- Layer by layer construction

- Smooth Wall Design

- Ultra-smooth flat walls

- Structure Strength

- No weld seams inside

- Layout Flexibility

- Flexible layout options

- Safety,Hygiene

- Safe and hygienic working environment

- Construction Compliance

- Meets European and local standards

- Support Structure

- Steel construction

- Discharge Efficiency

- Optimal product discharge

- Storage capacity increase

- 25% more than round silos

- Design flexibility

- Rectangular and modular layout options

- Product discharge

- Ultra-smooth flat walls enabling easy discharge

- Working environment

- Safe and hygienic

- Structural support

- Steel construction based on local regulations

- Cleanability

- Smooth flat walls, no weld seams inside

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Suitable for dry and granular bulk goods

- Abrasion resistance

- 25% more storage capacity, suited for abrasive materials

- Shape

- Square

- Footprint

- 25% more storage capacity than round silos on the same floor area

- Discharge Method

- Ultra-smooth flat walls for easy discharge

- Assembly Type

- Modular

- Structure Support

- Calculated steel construction, customizable

- Layout Options

- Flexible layout options, modular design

- Panel Material

- Steel

- Design Feature

- No weld seams on the inside

- Modular Design

- Layer by layer assembly

- Steel Construction Support

- Based on individual requirements

- Cell Sizes

- Various sizes by combining panels