Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and costly downtime with our advanced flow regulator, engineered to efficiently remove impurities and maintain production integrity.

Regulates and Cleans Grain Flow

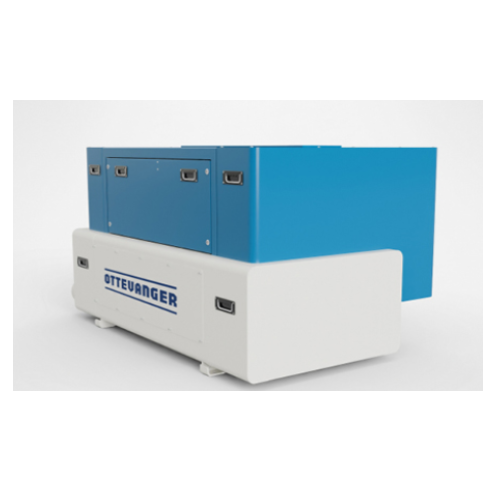

The Protector Roll Feeder by Ottevanger Milling Engineers is designed to enhance your roller mill operations by ensuring an even distribution of grains and cereals while filtering out impurities. This equipment is crucial for cleaning and purifying raw materials, reducing the risk of wear and potential downtime of your roller mills. The integrated feeder roll ensures consistent flow, while an embedded permanent magnet captures magnetic particles. With a high-capacity stationary and vibrating screen, it handles up to 60 tons per hour, optimizing both process efficiency and machine protection. Ideal for applications in grain, cereal, and feed industries, it supports production lines of cornflakes, poultry feed pellets, and more. Featuring variable amplitude settings and frequency control, this system offers seamless automation and integration into existing setups, making it a reliable choice for continuous, high-speed operations. The heavy-duty steel construction and optional screen executions cater to various product types, ensuring durability and adaptability in diverse processing environments.

Benefits

- Protects roller mills by filtering impurities, minimizing maintenance and repair needs.

- Ensures consistent material flow, reducing operational interruptions and enhancing productivity.

- Captures metallic contaminants with an integrated magnet, safeguarding downstream equipment.

- Customizable screen configurations optimize processing for varied product types.

- Enhances operational efficiency with adjustable vibration settings for diverse applications.

- Applications

- Grains, Feeds, Pet food, Cereals, Soybean processing, Aqua feed, Concentrates, Premix, Compound feed

- End products

- Muesli base flakes, Dog food kibbles, Cornflakes, Mineral premix, Cat food kibbles, Shrimp feed, Nutrient concentrates, Poultry feed pellets, Granola, Soy protein concentrate, Livestock pellet feed, Fish meal, Soybean meal, Vitamin premix

- Steps before

- Grinding, Pre-cleaning, Dosing, Weighing

- Steps after

- Milling, Structurizing

- Input ingredients

- grains, cereals, mixture, raw materials

- Output ingredients

- evenly distributed grain flow, cleaned flow, collected impurities

- Market info

- Ottevanger Milling Engineers is renowned for designing and manufacturing innovative milling equipment and complete production lines for the grain processing industry, including feed mills, flour mills, and biomass processing, with a reputation for quality, efficiency, and customized solutions.

- Capacity

- 25 – 60 t/h

- Drive roll feeder

- 1 x 2, 2 kW frequency controlled

- Vibrator motor

- 2 x 0, 17 kW

- Drive discharger

- 1 x 0, 37 kW

- Flow Regulation

- Even spread flow of grain over mesh screen

- Particle Separation

- Permanent magnet for magnetic particles

- Screen Type

- Stationary and vibrating strip

- By-pass valve

- Redirection of big particles

- Spiral Screw Discharge

- Removal of impurities

- Even spread flow control

- Integral feeder roll

- Magnetic impurity capture

- Permanent magnet

- Screen vibration control

- Amplitude adjustable

- By-pass valve function

- Directs large particles back to rollermill

- Impurity discharge method

- Spiral screw

- Vibrating screen adjustment

- Amplitude adjustable

- Flow protection

- Ensures even distribution

- Roller mill protection

- Against wear and damage

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Screen deck execution

- Product specific

- By-pass valve

- Enable redirection

- Vibration amplitude

- Adjustable

- Capacity

- 25 – 60 t/h