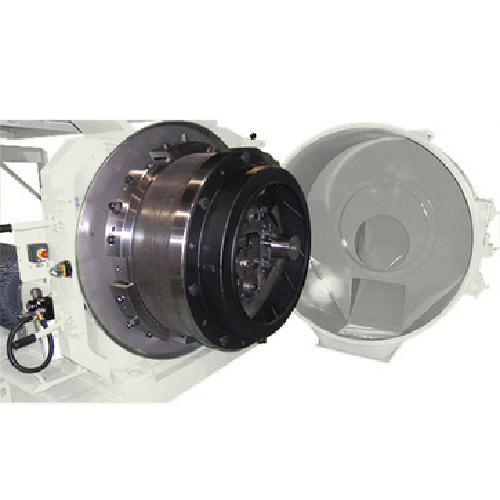

High-capacity pelletizer for oilseed meal processing

Maximize throughput and ensure consistency in your pelleting process with a high-efficiency solution designed for continuous, high-capacity operations, ideal for transforming diverse raw materials into uniform, high-quality pellets.

Processes Raw Material into Uniform Pellets

The 9000 Series Pellet Mills from CPM are engineered to handle high-capacity production needs across various industries, including animal feed, biomass, and food processing. These mills are designed with a positive direct gear drive that achieves 98% energy transfer and modular gearbox design for flexible production. With the option of a single motor for increased efficiency and features like an IC lube system and metal-to-metal seals, they ensure quieter operation and reduced wear. The 9036 model is ideal for applications requiring a high horsepower-to-working-die surface area, while the 9042 model accommodates larger die areas necessary for oilseed meal and broiler feed production. These mills can process up to 70+ horsepower with optional features such as roll speed measurement and an automatic grease system for enhanced operational control. Constructed from durable materials with stainless steel pellet chambers, the 9000 Series is suitable for continuous, automated operations with easy integration into existing production lines. Additionally, these mills provide customization options for working area and die RPM, tailored to specific application requirements, ensuring optimal performance and efficiency.

Benefits

- Maximizes production efficiency with a 98% energy transfer through direct gear drive.

- Reduces operational noise and wear with advanced metal-to-metal seals.

- Enhances production flexibility and scalability with modular gearbox design.

- Decreases maintenance time with quick-change bear claw die clamps.

- Supports high-capacity output for diversified applications like animal feed and biomass pellets.

- Applications

- Broiler feeds, Animal feed, Aquaculture, Pet food, Hemp, Food industry, Oilseed meal, Hops, Rendering, Biomass

- End products

- Soybean meal pellets, Breakfast cereal pellets, Hemp pellets, Wood pellets, Meat and bone meal pellets, Dog food pellets, Chicken feed pellets, Hop pellets, Fish feed pellets, Cattle feed pellets

- Steps before

- Grinding, Oilseed Preparation

- Steps after

- Cooling, Packing

- Input ingredients

- oilseed meal, broiler feeds

- Output ingredients

- pellets

- Market info

- CPM is known for manufacturing high-quality process equipment and technology solutions for the industrial and agricultural sectors, specializing in particle size reduction, conditioning, and pelleting solutions with a strong reputation for reliability and innovation.

- Die ID

- 36 in - 46 in / 914 mm - 1168 mm

- Die Width

- 9.4 in - 14 in / 239 mm - 356 mm

- Die Working Area

- 1, 063 in² - 2, 022 in² / 6, 860 cm² - 13, 000 cm²

- HP

- 600 - 700

- RPM

- 140 - 200

- Lube System

- IC lube system

- Feeder

- Multi-positioning feeder

- Drive

- Positive direct gear drive

- Gear Case

- Rounded cast gear case

- Motor

- Single motor

- Seal Type

- Metal-to-metal seals

- Gearbox Design

- Modular gearbox design

- Flange

- Replaceable quill flange

- Die Changes

- Bear claw die clamps - segmented

- Optional Feature

- Enforcer die feeder

- Optional Feature

- Lineator

- Roll Speed Measurement

- RSM (9042 model)

- Pre-wiring Terminal Box

- Available

- Automatic Grease System

- Available

- Working mechanism

- Positive direct gear drive

- Die change method

- Bear claw die clamps - segmented

- Noise level

- Rounded cast gear case for quieter operation

- Operational flexibility

- Modular gearbox design

- Energy transfer efficiency

- 98% energy transfer

- Efficiency

- Single motor for greater efficiency

- Quieter operation

- Internal ribbing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Die Size

- 9036

- Die Width

- 9036

- Die Working Area

- 9036

- Modular Gearbox Design

- Yes

- Single Motor

- Yes

- Stainless Steel Pellet Chamber

- Yes

- Replaceable Quill Flange

- Yes

- Pellet Chamber

- Stainless Steel

- Feed Method

- Multi-positioning feeder

- Optional Features

- Enforcer die feeder, Lineator, Roll speed measurement

- Control panel type

- UL508A Control Panel

- Feeder type

- Multi-positioning feeder

- Die attachment method

- Bear claw die clamps

- Seal type

- Metal-to-metal seals

- Gearbox design

- Modular gearbox

- Main motor setup

- Single motor

- Optional automation features

- Enforcer die feeder, Lineator, Roll speed measurement

- Lubrication system

- IC lube system

- Quill flange type

- Replaceable quill flange