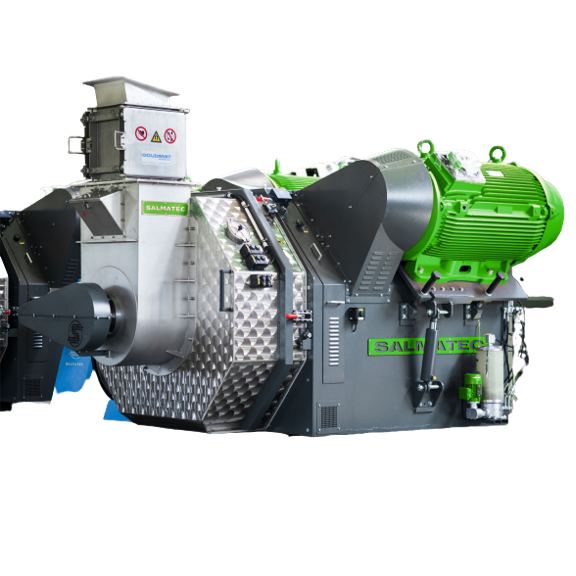

Complete pellet line

Large industries are shifting towards more environment-friendly technology, such as recycling wastes and utilizing them as an alternate energy source. For instance, sawdust and wood chips from wood mills are collected and processed into pellets which can be used in households or large industrial plants as a source of energy for heating systems. Plastic waste can also be recycled and made into pellets. Later these will be used in injection and molding machines to produce bottles, containers, or bags.

Turning wood and plastic byproducts into uniform pellets using a complete pelletizing system

The Complete Pellet Line from SALMATEC is a pelletizing system that includes multiple processes from conditioning raw materials and turning them into uniformly sized pellets. The entire system is specifically designed for the required product specifications. The conditioner helps the products achieve the optimum amount of moisture before feeding them to the pelletizer. The moisture content of raw materials can be controlled through a conditioning system in which the product moves inside a chamber while steam is also injected.

The pelletizer can be equipped with 2 or 3 rollers and multiple knives to cut the extruded products from the die into the necessary pellet size. The pellets then go to the cooler to prevent them from sticking to each other before storing them for at least one day in the silos. This process allows the structure of the pellets to stay intact and prevents them from breaking into tiny particles. Each complete system is designed according to the desired production capacity, raw material input, and high safety standards.

Benefits

- Wide range of production capacity

- Conform to the latest safety regulations and guidelines

- Homogeneous mixing of basic components

- Compatibility of all equipment provides smooth operation

- Safety features such as overload flap, temperature control, and safety switches