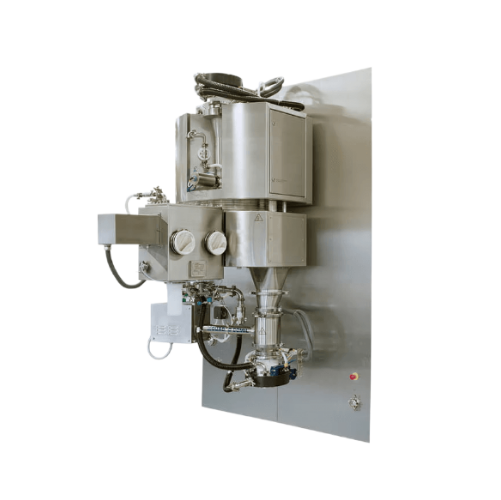

Single pot processor for granulation and drying

Streamline your pharmaceutical production with an integrated solution that combines mixing, granulation, and drying into a single vessel, optimizing space and reducing handling steps while ensuring high yield and efficiency.

Integrates Mixing, Granulation, and Drying in One Unit

The UltimaPro Single Pot Processor from GEA offers an integrated solution for pharmaceutical manufacturing, combining mixing, granulation, and drying within a single vessel. This design minimizes material handling and maximizes containment, ideal for producing pharmaceutical granules, effervescent tablets, and highly potent compounds. With vacuum and microwave drying options, the UltimaPro ensures rapid processing while maintaining energy efficiency. Its intelligent control system allows seamless integration into automated production lines, offering flexibility from batch to high-speed operations. Available in various configurations, the processor supports numerous end-products like paracetamol granules and vitamin C effervescent tablets, adhering to GMP compliance for pharmaceutical industries. Designed for easy maintenance, it includes CIP systems for efficient, contamination-free cleaning, with a robust design that withstands various chemical processes. Customization options are offered, alongside engineering support, to tailor solutions for specific production needs.

Benefits

- Streamlines production with integrated mixing, granulation, and drying, reducing handling steps and labor costs.

- Enhances processing of moisture-sensitive and potent compounds through high containment levels.

- Saves space and capital investment by combining multiple processes in one compact unit.

- Minimizes energy consumption with efficient vacuum and microwave drying technologies.

- Ensures rapid and efficient product changeovers, supporting facilities with diverse product lines.

- Applications

- Organic solvent-based granulations, Pharmaceutical tablets, Effervescent granules, Highly potent compounds, Toxic compounds, Pharmaceutical granules

- End products

- Ibuprofen tablets, Antibiotic granules, Paracetamol granules, Codeine phosphate granules, Hormone tablets, Aspirin granules, Sodium bicarbonate effervescent powders, Antineoplastic drugs, Vitamin c effervescent tablets, Beta-lactam antibiotics

- Steps before

- Dry Mixing, Liquid Addition

- Steps after

- Sizing, Tablet Pressing, Packing, Coating

- Input ingredients

- pharmaceutical compounds, organic solvents, wet granulation materials, active ingredients, highly potent compounds, effervescent ingredients, toxic materials

- Output ingredients

- pharmaceutical granules, dried granules, effervescent granules, low moisture content products, solvent vapors, toxic product containment

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- PLC-controlled

- Bowl Volume

- 7.9–1166 Litres

- Typical Batch Weight @ 0.6 g/ml

- 3–480 kg

- Drying Options

- Vacuum / Microwave

- Vacuum Level

- <3 mbar

- Changeover time

- <2 hours

- Containment Level

- High containment (Hicoflex®, MC valves)

- Vacuum System

- Efficient with HEPA filter

- Microwave Drying Presence

- Optional

- Working Mechanism

- Integrated mixing, granulation, and drying

- Integrated Steps

- Dry mixing, liquid addition, granulation, drying, sizing

- Automation Level

- PLC-controlled

- CIP/SIP

- Automated CIP system

- Changeover Time

- < 2 hours

- Batch vs. Continuous Operation

- Batch operation

- Energy Efficiency

- Low energy input due to vacuum drying

- Cleaning Method

- CIP

- Drying Integration

- Vacuum and microwave assisted

- Gas-assisted Vacuum Drying

- Transflo technique

- Swinging Bowl

- Reduces drying time and improves granule characteristics

- Cleanability

- Easy and efficient cleaning (CIP)

- Granulation method

- Wet / Melt / Pelletizing

- Drying method

- Vacuum / Microwave

- Effervescent production

- Water-based / Solvent-based

- Contained production

- Highly potent / Toxic products

- Solvent recovery system

- Vacuum condenser

- Batch weight range

- 3–480 kg

- Contained sampling

- Valve integrated

- Bowl Volume

- 7.9–1166 Litres

- Typical Batch Weight

- 3–480 kg

- Control panel type

- PLC-controlled / Touch HMI

- Integration possibilities

- SCADA / ERP systems

- Vacuum system configuration

- Standard / Enhanced with microwave

- Bowl volume selection

- 1025 - 1200 liters

- Containment solutions

- Hicoflex®, MC valves

- Drying options

- Vacuum / Microwave / Gas-assisted