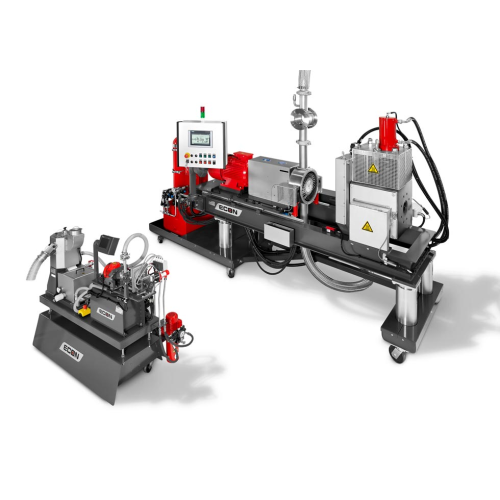

Underwater pelletizing system for thermoplastic materials

Optimize your thermoplastic pellet production with a reliable underwater pelletizing solution that ensures consistent pellet quality and efficient drying, minimizing maintenance demands and energy consumption.

Pelletizes and Dries Thermoplastics Efficiently

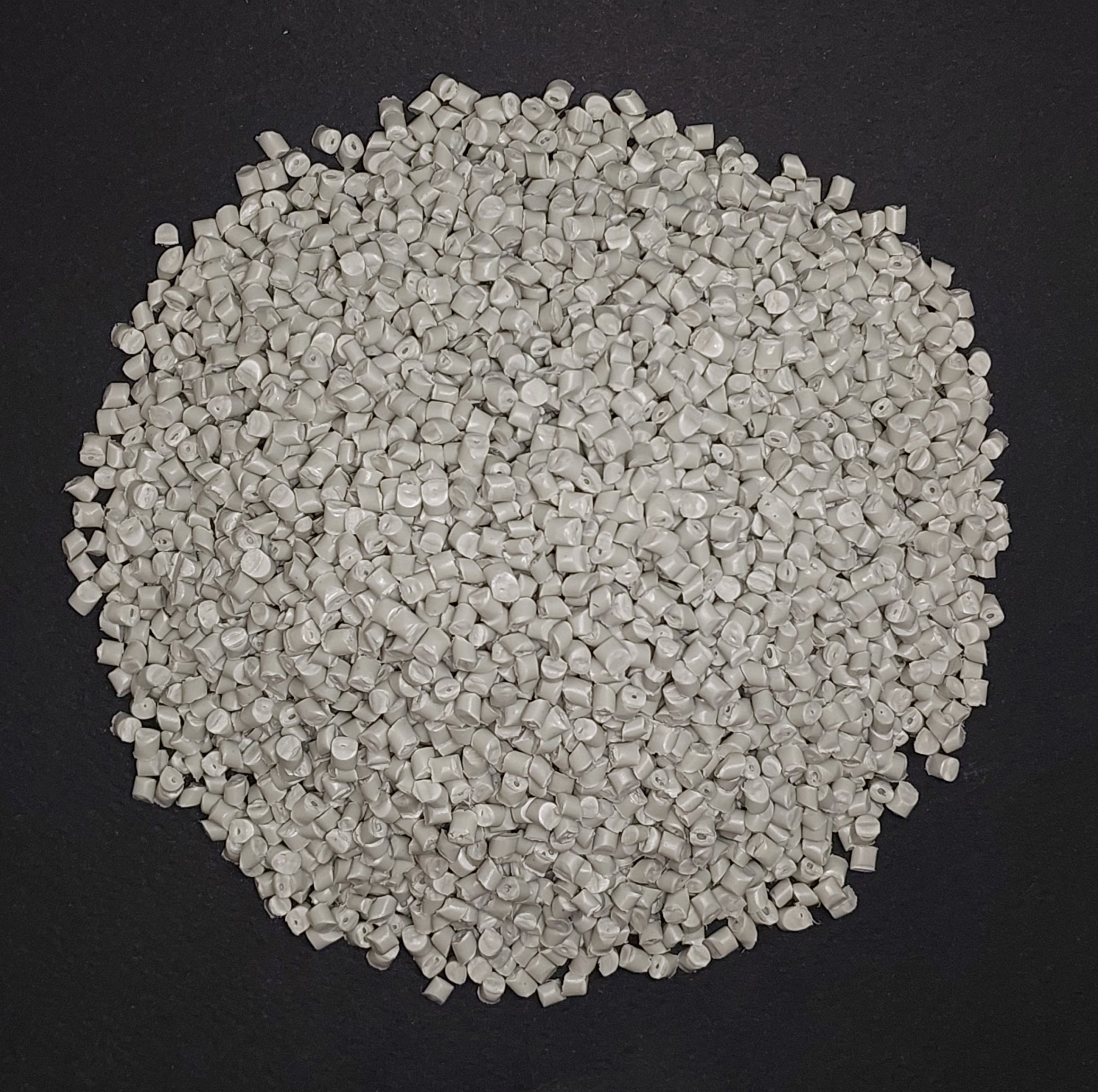

The ECON EUP series offers superior underwater pelletizing and drying solutions tailored for the plastics and polymer sectors. Each unit features a thermally insulated die plate that prevents material solidification, ensuring seamless pellet production even with fluctuating output rates. Ideal for creating polypropylene granules, polyethylene micro pellets, and more, the system guarantees consistent pellet quality and minimal labor costs.

The EUP series integrates a polymer diverter valve, a pelletizing unit, a water treatment and drying system, and an efficient electrical control system, operating continuously and automatically. Its processing throughput ranges from 30 kg/hr to 15,000 kg/hr, adaptable across varying thermoplastic materials. This adaptability is supported by plug-and-play setup, which includes water treatment and centrifugal drying modules.

With a focus on energy efficiency, the system’s compact design reduces energy consumption, complemented by features like continuous process water filtration and optional automatic band filters. Maintenance is simplified through easy access to components and lack of bypass piping, minimizing upkeep demands. Constructed for durability, the LONGLIFE® die plate extends operation longevity, while optional customization supports varied production goals.

Benefits

- Ensures consistent pellet quality by preventing die hole freezing with thermal insulation.

- Enhances operational efficiency with seamless adaptation to varying production conditions.

- Minimizes maintenance efforts through easily accessible components and no bypass piping requirement.

- Lowers energy expenditure with an optimized, compact design and optional process water filtration.

- Expands production versatility, accommodating a wide range of thermoplastics and micro pellet sizes.

- Applications

- Thermoplastics, Granules, Micro pellets

- End products

- Polyethylene micro pellets, Pet granules, Polypropylene granules, Pvc granules, Nylon micro granules, Polystyrene micro pellets, Abs micro pellets

- Steps before

- Polymer Melt Preparation, Material Pre-treatment

- Steps after

- Cooling, Quality Control, Packaging

- Input ingredients

- thermoplastic materials, melt, polymer

- Output ingredients

- pellets, micro pellets, granules

- Market info

- Throughput capacity

- 30 kg/hr to 15, 000 kg/hr

- Pellet size

- Standard granules and micro pellets

- Energy consumption

- Minimal energy consumption, highest energy savings

- Automation

- Push-button start - automatic, fast and safe

- Pellet quality

- Constant pellet quality

- Die plate

- Thermally insulated, LONGLIFE® die plate

- Cleaning and maintenance

- Easily accessible equipment, free of dead spots

- Filtration system

- Continuous process water filtration

- Adaptability

- Easily adapted to different production conditions

- Cutter

- Hydraulic lock for pelletizer housing

- Water treatment and drying system

- Compact design, low maintenance

- Cooling system

- Cooling circuit with plate heat exchanger

- Working mechanism

- Underwater pelletizing

- Integrated steps

- Pelletizing, water treatment, drying

- Operation type

- Continuous

- Thermal insulation

- Prevents die hole freezing

- Automation level

- Automatic push-button start

- Energy efficiency

- Minimal energy consumption

- Cleaning method

- Easy access, no dead spots

- Changeover time

- Quick, adaptable to conditions

- Abrasion resistance

- Yes

- Biological compatibility

- N/A

- Cleanability

- Easy

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Variable

- Machine Footprint

- Compact

- Die Plate Size

- Fixed to heated carrier body

- Feed/Discharge Method

- Underwater, continuous

- Control Panel Type

- Push-button start

- Compact Footprint

- Minimal space requirements

- Discharge Method

- Through process water and drying system

- Component Configuration

- PLUG, PLAY with diverter valve

- Die Plate Type

- Thermally insulated, highly wear-resistant (LONGLIFE®)

- Unit Design

- Compact, minimal space requirements

- Water Treatment System

- Continuous filtration, optional automatic compact band filter

- Pellets Size

- Smallest possible pellets, even micro pellets

- System Components

- Optional components for individual requirements

- Operational Adaptability

- Adaptable to different production conditions

- Energy Consumption

- Minimal energy consumption with high energy savings

- Cleaning Accessibility

- Easily accessible pellet dryer free of dead spots

- Operational Start

- Push-button start, automatic, fast, and safe