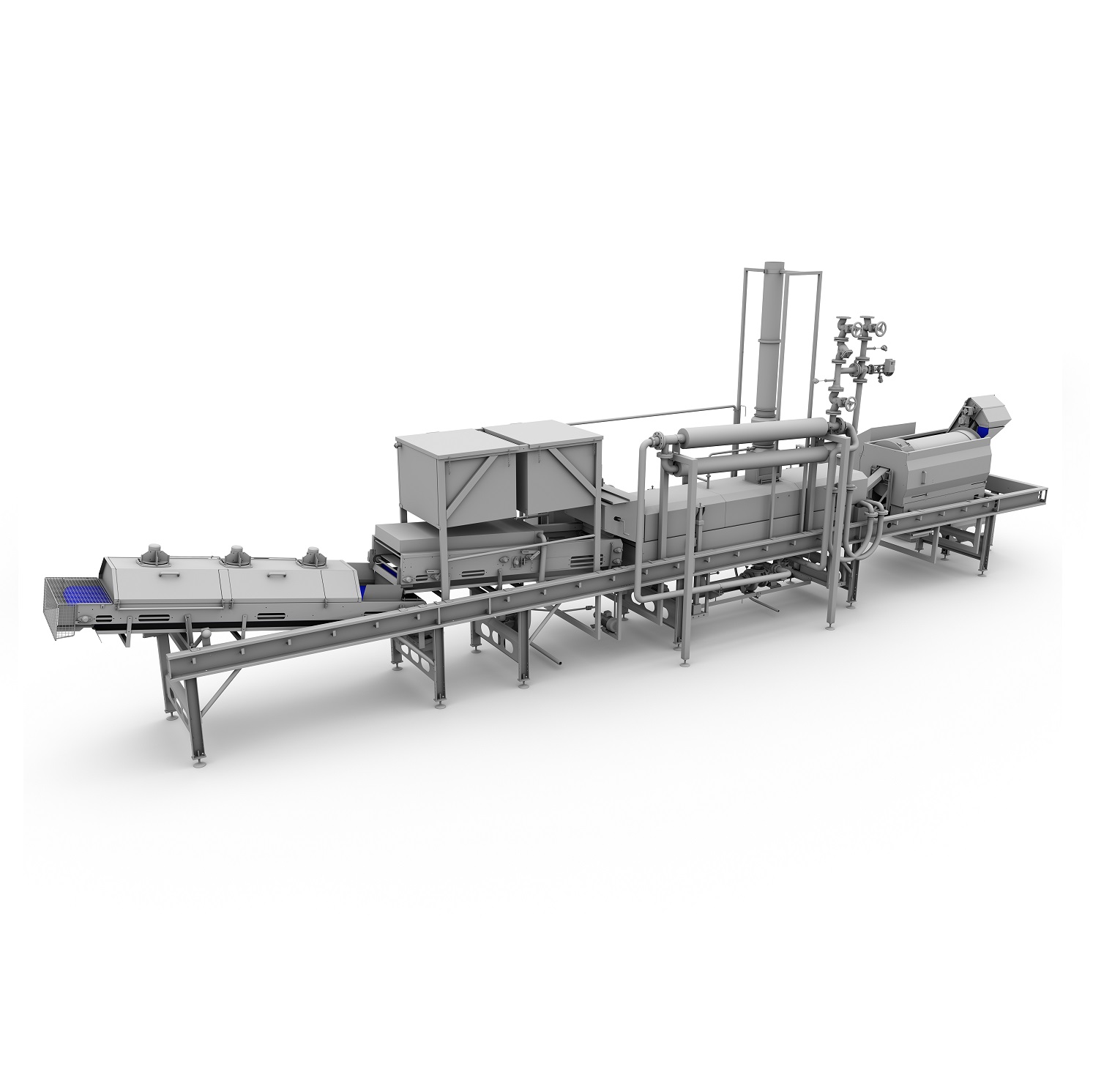

Pellet snacks frying line

Pellet-style snacks represent a broad food sector category. They are consumed worldwide and vary according to the market. Popular types include prawn crackers, puffed cheese, pork rinds, and bugles, to name a few. Under the right frying conditions, these snacks expand and acquire the crispy texture that makes them such popular nibbles. However, transferring the pellet snack through the frying line is a delicate process that could compromise the final product.

Transfer fried pellet snacks gently through the production cycle

The PP snack pellet frying line from Kuipers combines an efficient transportation system designed for pellet-style snacks. Also, the deep fryer uses gentle heat transfer technology to ensure consistent cooking to preserve the desired flavor and texture as the pieces move to the next production stage.

In addition, a dirt removal system at the pre-frying stage maintains oil quality for longer. Furthermore, the automatic PP system is fully controlled via PLC and handles production of 50 kilograms per hour output to 1,000 kilograms per hour output.

In order to produce different varieties of pellet snacks, you need different temperatures and frying time. Fortunately, this piece of equipment is completely adjustable in terms of frying time and temperature which means it can be used to make a wide array of snack pellets.

Kuipers have created a way to remove dirt from the oil which means that the oil does not need to be changed. This results in higher quality oil which is essential when deep frying these types of food products.

Benefits

- Lowest frying oil turnover time

- Gentle heat transfer

- Low frying oil turnover time

- Pre-fry dirt removal

- 50-1000 kg/h output