Industrial water bath for pelletizing processes

Enhance pellet quality and efficiency with a customizable water bath designed to ensure optimal cooling and precise strand alignment in your polymer extrusion line.

Cools and Aligns Polymer Strands

The WBX Series Water Bath from Bay Plastics Machinery is a custom-engineered solution designed for polymer extrusion processes. This water bath optimizes pellet cooling and strand alignment, crucial for producing polyethylene pellets, polypropylene granules, and more. It incorporates adjustable legs and quick-releasing hold-down bars with UHMWPE rollers to maintain strand straightness and reduce friction. Bay Plastics offers optional water recirculation systems featuring pumps, heat exchangers, and automatic water make-up circuits for maintaining optimal operation and compensating for evaporation. With a variety of models, the WBX Series is adaptable to most extrusion applications, ensuring seamless integration into your production line.

Benefits

- Enhances product quality by ensuring precise cooling and alignment of polymer strands.

- Customization options provide flexibility to fit specific extrusion requirements.

- Reduces operational costs with automated water recirculation and evaporation compensation.

- Minimizes maintenance with durable UHMWPE rollers that decrease strand friction.

- Seamlessly integrates into existing pelletizing lines, enhancing overall productivity.

- Applications

- Polymers, Extrusion applications, Plastics, Pelletizing, Thermoplastics

- End products

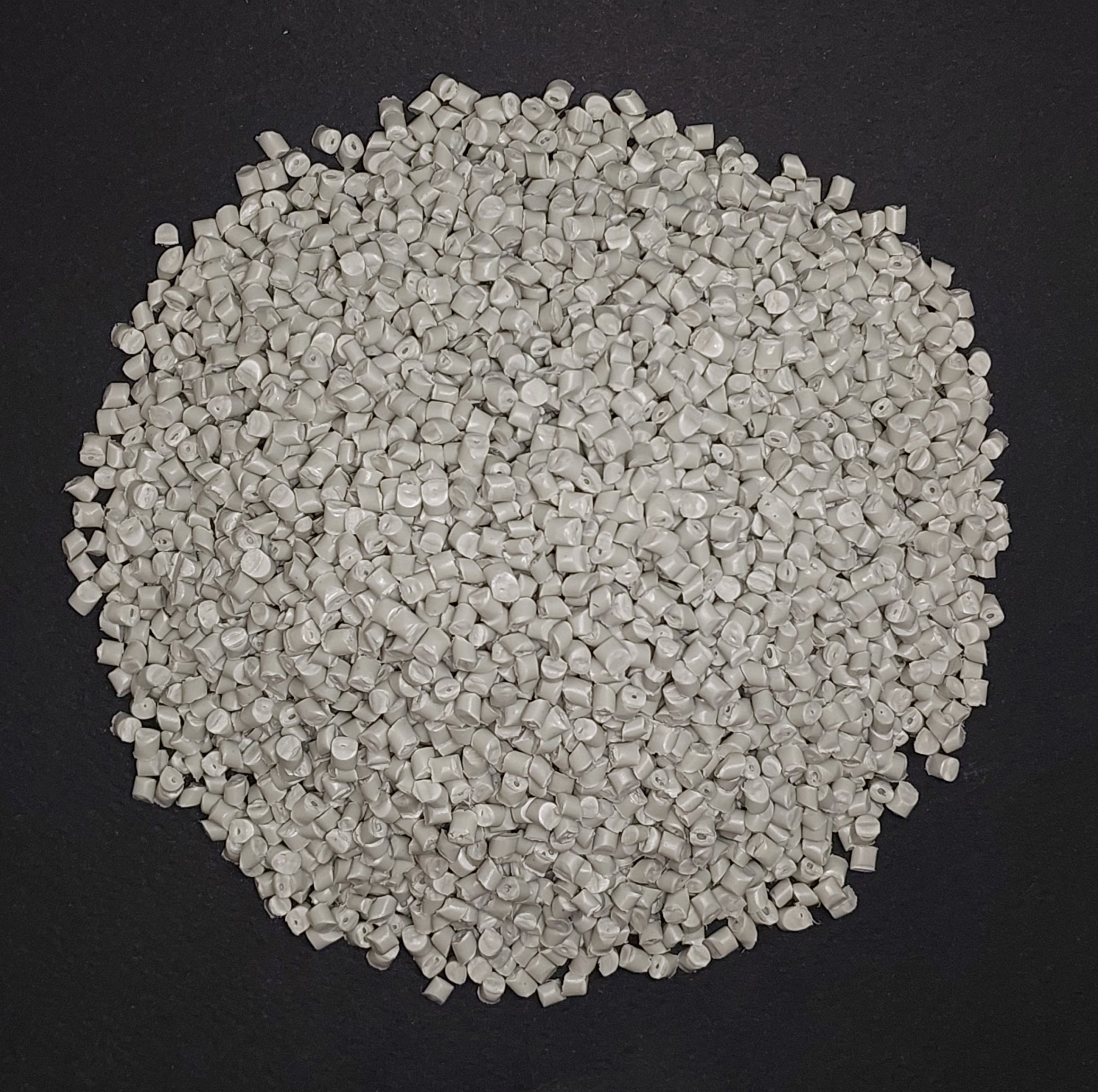

- Polyethylene pellets, Thermoplastic elastomers, Polypropylene granules, Polystyrene beads, Nylon pellets, Bio-based polymer pellets, Styrenic block copolymers, Abs resins, Pet flakes, Pvc compounds

- Steps before

- Extrusion preparation, Material feeding, Pre-heating, Pelletizing setup

- Steps after

- Strand alignment, Dewatering, Drying, Cooling

- Input ingredients

- extrusion strands, plastic strands

- Output ingredients

- pelletized plastic, cooled extruded strands

- Market info

- Bay Plastics Machinery is known for manufacturing pelletizing equipment and systems, recognized for their innovation and quality in the plastics industry. They specialize in developing customized solutions for polymer processing, focusing on efficiency and reliability.

- Adjustable Legs

- Yes

- Hold-Down Bars

- 3-5 bars

- Roller Diameter

- 2 inches

- Roller Material

- UHMWPE

- Water Recirculation System

- Customizable

- Heat Exchanger Options

- Sealed plate, plate-and-frame, shell-and-tube

- Model Sizes

- Variety

- Automatic Water Make-up Circuit

- Yes

- Automation level

- Manual with optional automated water recirculation

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Water recirculation system

- Custom design with pump, heat exchanger

- Hold-down mechanism

- Locking quick-releasing hold-down bars

- Strand alignment

- Grooved rollers

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies by model size, e.g., 66” x 6” x 6’ to 30” x 12” x 30’

- Tank shape and size

- Rectangular, dimensions based on model e.g., 6” width to 30’ length

- Customization options

- Custom shapes and sizes available

- Discharge method

- Locking quick-releasing hold-down bars, grooved rollers

- Roller material

- UHMWPE (Ultra-High-Molecular-Weight PolyEthylene)

- Adjustable features

- Adjustable legs

- Adjustable legs

- Yes

- Water recirculation system

- Custom design available

- Water make-up circuit

- Automatic

- Heat exchanger options

- Sealed plate, plate-and-frame, shell-and-tube

- Hold-down bars

- 3 to 5 depending on length