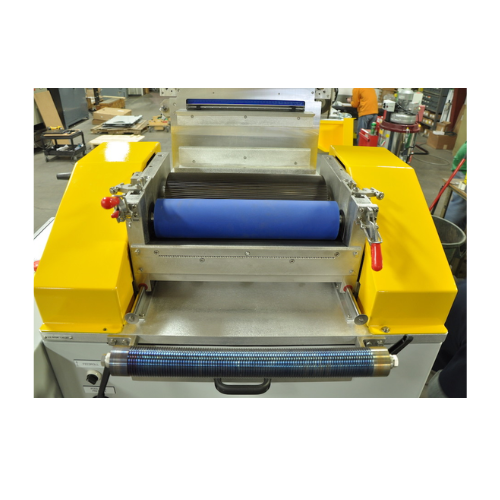

Micro pelletizer for thermoplastics

Achieve precision in micro pelletizing with a solution engineered to reduce turbulence, allowing for consistent production of polymer pellets as small as 0.015 inches.

Cuts and Pelletizes Micro-Sized Thermoplastic Strands

The X-Class Micro Strand Pelletizer from Bay Plastics Machinery is engineered to transform thermoplastics into precise micro pellets. It stands out due to its patented design, which minimizes turbulence, optimizing micropellet production. This pelletizer excels in cutting a broad range of materials, from polypropylene and polyethylene to glass-filled thermoplastics, into uniform pellets as small as 0.015 inches. Ideal for applications across plastics and polymer industries, it supports manual and lab-scale operations. Its robust construction features heavy-gauge stainless steel and requires no external gearbox, thanks to its internal upper feedroll drive system. Pneumatic cylinders provide substantial pulling force, and eccentric-mounted bearings ensure precise rotor gap settings. This efficiency in design not only ensures consistent product quality but also facilitates easy maintenance, reducing downtime and operational costs. The X-Class is a versatile solution for manufacturers aiming to produce consistent, high-quality micro pellets for diverse applications.

Benefits

- Maximizes production efficiency by precisely cutting thermoplastics into consistent micro pellets.

- Reduces operational costs through robust design that minimizes maintenance requirements.

- Enhances processing versatility, accommodating a wide range of thermoplastic materials.

- Ensures safety with an interlock system that prevents access when guards are in place.

- Improves long-term reliability with heavy-duty stainless steel construction and durable components.

- Applications

- Thermoplastics, Master batch, Glass-filled thermoplastics

- End products

- Reinforced plastic granules, Polyethylene micro beads, High-impact polystyrene beads, Colored plastic masterbatches, Polystyrene pellets, Glass fiber reinforced plastic pellets, Abs micro pellets, Nylon micro pellets, Polypropylene pellets

- Steps before

- Material preparation, Strand extrusion

- Steps after

- Pellet cooling, Pellet drying, Pellet packaging

- Input ingredients

- thermoplastics, master batch, glass-filled thermoplastics, strands

- Output ingredients

- micro pellets, pellets as small as 0.015 inches, micropellets

- Market info

- Bay Plastics Machinery is known for manufacturing pelletizing equipment and systems, recognized for their innovation and quality in the plastics industry. They specialize in developing customized solutions for polymer processing, focusing on efficiency and reliability.

- Pellet Size

- 0.015″ (0.4mm)

- Rotor Design

- Patent-pending

- Feedroll Drive System

- Internal upper feedroll drive

- Material Construction

- Stainless steel

- Bearings

- Eccentric-mounted bearings

- Bed Knife

- Four-edged, solid tungsten-carbide

- Drive Type

- AC variable frequency drive

- Pneumatic Cylinders

- Large bore cylinders

- Working Mechanism

- Micro strand pelletization

- Automation Level

- Manual / PLC-controlled

- Changeover Time

- Quick-release clamps

- Cleaning Method

- Accessible design for manual cleaning

- Batch vs. Continuous Operation

- Continuous

- Abrasion resistance

- Yes

- Thermoplastics

- Master batch to glass-filled thermoplastics

- Corrosive resistance (e.g. acids)

- Limited by material selection

- Density/particle size

- 0.4 mm length pellets

- US Patent

- #7, 393, 201

- Construction material

- Stainless steel

- Feed method

- Internal upper feedroll drive system

- Feedroll Drive System

- Simple internal upper feedroll drive system

- Pneumatic Cylinders

- Large bore cylinders

- Material Construction

- Heavy-gauge stainless steel

- Rotor Design

- Patent-pending rotor design

- Feedroll Covering

- Hypalon-covered upper feedroll

- Drive Type

- AC variable frequency drive

- Safety Interlock System

- Yes, with guards