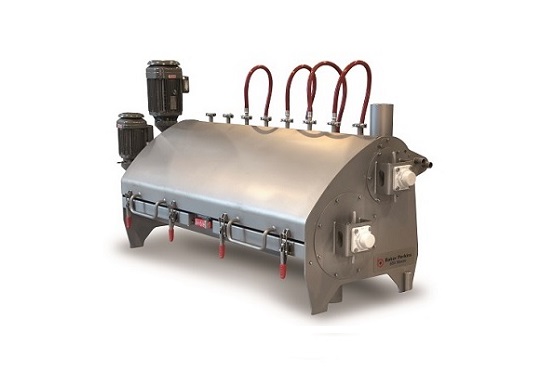

Pre-conditioner for breakfast cereals

Extruded breakfast cereal products are a popular and lucrative product class. In cases where high quality and maximum throughput are required, the use of a pre-extrusion treatment is highly beneficial thanks to the reduced cooking times and mechanical shear energy required in the extruder. This also widens the range of product that can be extruded in the final process.

Pre-conditioning for cereal products to improve extrusion results

The SBX Master Preconditioner from Baker Perkins is suitable for use in the production of high volume, high quality breakfast cereal and snack products. This unit pre-heats, mixes and hydrates your ingredients. High speed mixing and hydration are performed in separate chambers, allowing complete control over dwell time in each process. This enables perfect treatment to maximise the end-product quality.

As well as thoroughly aerating the pre-extrusion recipe, the high intensity mixing means hydration is more uniform and more controlled. It also allows for additional ingredients to be added before, during, or after hydration for use with complex and premium breakfast cereal and snack products.

By pre-heating pelletized ingredients before they enter the extruder, the SBX Master Preconditioner allows for increased cooling times, reducing unwanted expansion. Pretreatment of protein based products allows for a gentler extrusion, improving their texture in the finished cereal.

To minimise downtime associated with product changeover and cleaning, the SBX Master Preconditioner can be fitted with a Clean in Place spray bar to allow for rapid and hygienic clean down. The open construction allows easy all-round access for maintenance and cleaning.

Benefits

- Increase product quality by pre-treating product before extrusion

- Preserve textures and tastes by precisely hydrating and mixing ingredients

- Reduce downtime with clean in place systems for quick and hygienic changovers

- Add ingredients at any stage of preconditioning to allow for complex and premium products

- Reduces cooking times and shear energy in extruder, increasing range of ingredients able to be used