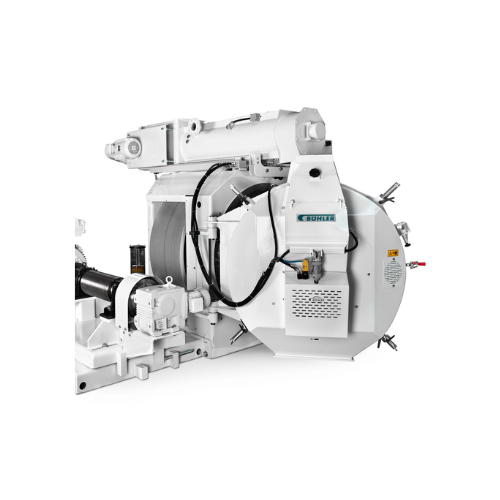

Pellet mill for biomass and sunflower hulls

Achieve high-speed, continuous production of durable pellets from varied materials, ensuring flexibility and precision in demanding processing conditions.

Processes Biomass into Pellets and Briquettes

The Pellet Mill RWPR from Bühler Group is engineered for robust biomass and animal feed production. Designed to withstand demanding conditions, it efficiently transforms finely ground wood, sunflower hulls, and grains into high-quality pellets and briquettes. With its integrated machine control system, it optimally conditions materials using water and steam, maximizing throughput and activating natural binders. Capable of continuous, high-speed operation, the RWPR features automatic lubrication and an inlet bypass to prevent blockages, ensuring smooth production. Particularly suitable for biomass processing and agricultural producers, it handles diverse raw materials and end-products ranging from wood heating pellets to kibble for pets and whole wheat flour. With optional materials and engineering support, it offers customization to meet specific production needs.

Benefits

- Maximizes production capacity by efficiently converting diverse raw materials into pellets and briquettes.

- Enhances operational safety with rugged paneling and automated control system, protecting operators from moving parts.

- Minimizes downtime with automatic lubrication and inlet bypass, ensuring continuous operation.

- Reduces maintenance efforts with easy user guidance and low cleaning requirements.

- Customizable die and roll options ensure consistent product quality tailored to specific raw materials.

- Applications

- Animal feed, Oilseeds, Pulses, Pet food, Wood pellets, Paddy, Wheat, Grain, Spices, Rice, Aqua feed, Biomass, Sunflower hulls

- End products

- Polished rice, Sunflower hull pellets, Livestock feed pellets, Whole wheat flour, Lentil flour, Aquaculture pellets, Wood heating pellets, Milled paddy rice, Kibble for pets, Grain-based malt, Biomass briquettes, Curry powder, Edible oil cake

- Steps before

- Conditioning, Grinding, Moisture Content Adjustment

- Steps after

- Cooling, Packing, Storage

- Input ingredients

- finely ground wood, straw, biomass particles, sunflower hulls

- Output ingredients

- industrial pellets, household pellets, high-grade pellets

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Throughput Capacity

- High throughputs with challenging raw products

- Abrasiveness of material

- Capable of handling abrasive materials

- Material Processing

- Wood, straw, sunflower hulls, biomass

- Automation

- Control system with automatic lubrication and inlet bypass

- Lubrication System

- Automatic with large grease container

- Die Configuration

- Customizable for specific raw materials

- Pressure Withstanding Capacity

- High-pressure tolerance

- Safety Features

- Rugged paneling and automatic press roll disengagement

- Cleaning Requirements

- Low

- Temperature Control

- Integrated monitoring

- Control Panel Type

- Integrated machine control system

- Roll Change

- On-machine mounting hoist option

- Automation level

- PLC controlled

- Changeover time

- Fast changeover with on-machine mounting hoist

- CIP/SIP

- Easy cleaning method with low maintenance

- Cleaning method

- Low maintenance

- Continuous production

- Automatic lubrication system

- Production flexibility

- Automatic inlet bypass

- Safety features

- Rugged paneling and pneumatic disengagement

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Die configuration

- Customizable

- Die size

- 6–25 mm

- Control panel type

- Integrated machine control system

- Discharge method

- Automatic inlet bypass

- On-machine mounting hoist option

- Extendable

- Control panel type

- Integrated machine control system

- Inlet bypass

- Pneumatically operated

- Lubrication system

- Automatic

- Roll change

- On-machine mounting hoist option