Bran duster for flour yield and ash content optimization

Enhance your milling efficiency by optimizing flour yield and precisely adjusting ash content, ensuring consistent quality in your cereal-based products.

Enhances Yield and Adjusts Ash Content

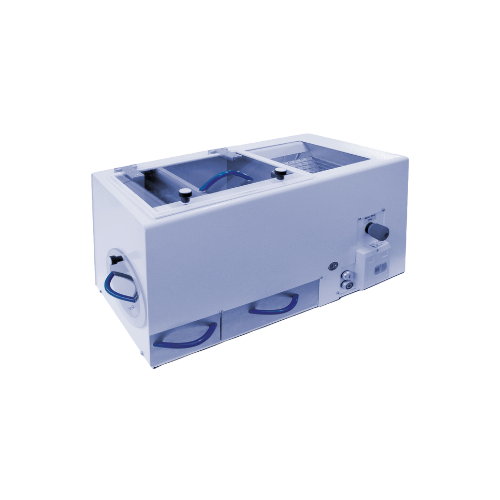

The Brabender Bran Duster is an essential tool for flour milling and food processing industries, significantly enhancing production by increasing flour yield and tailoring ash content in end-products such as whole wheat flour and bran flakes. It features a sophisticated sifting mechanism with a standard mesh size of 200 µm, customizable to meet specific requirements, and operates efficiently with a throughput of up to 12 kg/h. Its continuous, manual operation is ideal for small-scale use, providing precise separation and yield enhancement. Maintenance-free by design, it integrates seamlessly into existing cereal and grain processing lines. Customizable options and engineering support are available to cater to varying operational needs.

Benefits

- Increases flour yield by up to 10%, optimizing raw material utilization.

- Precise ash content adjustment enhances product quality and meets specific industry standards.

- Operates continuously with minimal manual intervention, boosting processing efficiency.

- Maintenance-free design minimizes downtime and reduces operational costs.

- Customizable mesh sizes provide flexibility for diverse application needs.

- Applications

- Cereals, Flour, Milling products

- End products

- Wheat germ, Whole wheat flour, Cornmeal, Oat flour, Rye flour, Bran flakes, Muesli base

- Steps before

- Grinding

- Steps after

- Quality Assessment, Packing

- Input ingredients

- ground product, flour

- Output ingredients

- flour with increased yield, increased ash content

- Market info

- Brabender is renowned for producing high-quality, engineered-to-order lab equipment for material testing, particularly in food and plastics industries, specializing in precision instruments for measuring, preparation, and processing.

- Yield increase

- Up to 10%

- Throughput

- Up to 12 kg/h

- Mesh size

- 200 µm (others available upon request)

- Ash content increase

- Adjustable

- Maintenance requirement

- Maintenance-free

- Automation level

- Manual / Automated

- Batch vs. continuous operation

- Batch

- Cleaning method

- Maintenance-free

- Changeover time

- Minimal

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Ash content control

- Precisely set and increased

- Separation performance

- Excellent

- Mesh size customization

- Other sizes available upon request

- Mesh size

- 200 µm (others available upon request)

- Maintenance-free design

- Standard

- Throughput

- Up to 12 kg/h