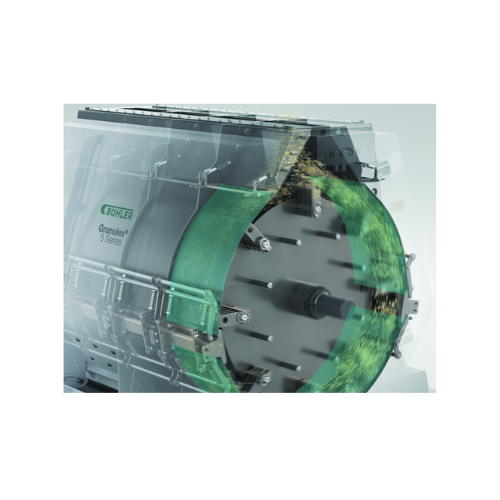

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to efficiently handle solid, powder, and granule forms in high-speed continuous operations, ensuring consistency and safety in every step of your production line.

Grinds and Mills for Efficient Processing

The Horizontal Hammer Mill from Bühler is an expertly engineered solution designed for continuous, high-speed grinding and milling. This versatile equipment efficiently processes solids, powders, and granules, making it suitable for industries like food, feed, and biomass. With robust construction and a user-friendly design, it incorporates advanced safety features such as explosion protection and automatic feed systems, ensuring operator security and consistent performance. This mill seamlessly integrates with your production line, offering comprehensive processing from raw material storage and conveying to grinding, extruding, and packaging. It supports diverse applications, including the production of cattle feed pellets, fish meal, and wood pellets. Opt for stainless steel materials to enhance corrosion resistance, and rely on Bühler’s engineering support for customized solutions that align with specific throughput requirements, optimizing production capacity and efficiency.

Benefits

- Enhances production efficiency with continuous high-speed grinding.

- Reduces operational risk with integrated explosion protection systems.

- Lowers energy usage through optimized motor control.

- Streamlines processes by integrating seamlessly into complete production lines.

- Minimizes maintenance downtime with durable construction and easy-access design.

- Applications

- Brewery, Animal feed, Premix and concentrates, Pet food, Oilseed, Grain processing/milling, Aqua feed, Biomass

- End products

- Dog kibble, Wheat flour, Vitamin and mineral premixes, Cattle feed pellets, Wood pellets, Fish meal, Malted barley, Soybean meal

- Steps before

- Storage, Weighing, Sieving, Conveying, Hoppers, Gates, Feeding, Extruding, Mixing

- Steps after

- Drying, Coating, Packing, Palletizing

- Input ingredients

- raw material, grain, oilseed, biomass

- Output ingredients

- finished product, processed grain, oil, feed

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Automation

- PLC-controlled

- Capacity

- Varies based on specific requirements

- Compliance with explosion protection

- Yes

- Feed type

- Dry / Wet / Granular

- Grinding lines features

- Complete with sieving, conveying, storage, hoppers, gates, feeders, automation, fans, filters

- Safety features

- Explosion protection, operator safety

- Material compatibility

- Various raw materials

- Innovations

- Mechanical, process, digital solutions

- Integration capabilities

- Weighing, mixing, grinding, extruding, drying, coating, packaging

- Product testing

- Application Centers worldwide

- Working mechanism

- Hammer milling

- Integrated steps

- Sieving, conveying, storage

- Automation level

- PLC controlled

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Manual / CIP

- Safety features

- Explosion protection

- Energy efficiency

- Optimized kWh/kg

- User-friendliness

- High operator safety

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Pasty/Liquid/Granular

- User interface

- HMI/Touchscreen

- Footprint customization

- Compact / Modular

- Explosion protection levels

- ATEX / NFPA

- Material options

- Stainless steel / Carbon steel

- Automation level

- PLC / SCADA