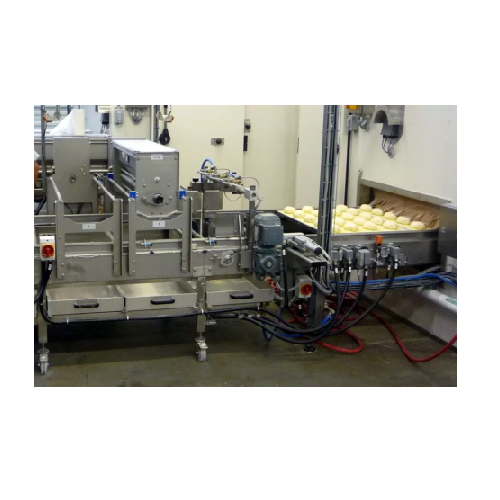

Bread topping system for consistent seed and flour application

Achieve precise topping consistency with our system, designed for seamless integration in your bakery line, ensuring your bread products are evenly coated with seeds or flour for enhanced visual and textural appeal.

Applies and Scores Bakery Toppings

The Kaak Topping and Scoring System is a versatile solution tailored for commercial bakeries and industrial food producers, excelling in the precise application of seeds, grains, and pastes. Featuring customizable dosing settings and an easy-to-remove fill funnel, this system ensures efficient and hygienic operations. It utilizes a variable-speed dispensing roll developed to meet specific production requirements, making it ideal for continuous batching and high-speed manual operations. Perfectly suited for products ranging from baguettes to seeded pizza crusts, this equipment seamlessly integrates with upstream mixers and sheeting systems, delivering uniform coverage and consistent scores. Designed with a focus on hygiene and maintenance, components such as seed and flour dispensers are easily accessible for cleaning, ensuring minimal downtime.

Benefits

- Ensures consistent topping application, enhancing product appearance and quality.

- Reduces cleaning time with a quick-release fill funnel design.

- Supports high-speed operations, increasing production efficiency.

- Offers customizable configurations, meeting specific production needs.

- Minimizes noise levels for a quieter workplace environment.

- Applications

- Buns, Freestanding bread, Pizza, Tin bread, Rolls, Baguette

- End products

- Sesame seed rolls, Seeded pizza crust, Rustic freestanding bread, Multi-seed tin loaf, Poppy seed buns, Baguette sticks

- Steps before

- Dough Make-Up, Mixing, Sheeting

- Steps after

- Scoring, Product handling, Baking, Cooling

- Input ingredients

- dough, grains, seeds, kernels, rice paste

- Output ingredients

- decorated bread, tiger bread, scored bread, topped rolls, embellished crust

- Market info

- Royal Kaak is renowned for designing and manufacturing industrial bakery equipment, specializing in automated production lines and custom-engineered solutions, delivering innovative, efficient, and reliable equipment to enhance bakery production processes worldwide.

- Noise level

- Low

- Dosing consistency

- Consistent

- Hygienic design

- Yes

- Cleaning,maintenance accessibility

- Easy removal of fill funnel

- Variable speed

- Yes

- Noise Level

- Little noise

- Cleaning/maintenance access

- Easy removal of fill funnel

- Cleanability

- Yes

- Density/particle size

- Varied (e.g., seeds, grains, kernels)

- Corrosive resistance

- Yes (Hygienic Design)

- Decorative Topping

- Grains, Seeds, Kernels

- Topping Methods

- Scoring, Paste Application

- Machine footprint

- Compact design

- Discharge method

- Variable speeds

- Control panel type

- Variable controls

- Hygienic design

- Easy to clean

- Removable components

- Fill funnel easily removable for cleaning

- Dispensing roll

- Made to measure

- Variable Speeds

- Customizable

- Custom Dispensing Roll

- Made to measure

- Control Integration

- Customer's wishes