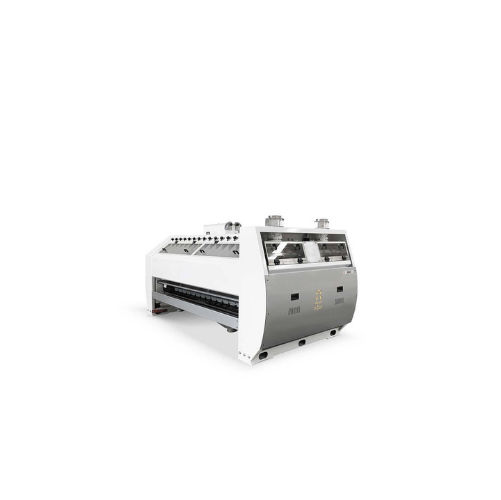

Semolina purifier for milling operations

Achieve precise separation and classification of semolina and bran with this purifier, ensuring your end-products meet the highest quality standards by meticulously removing impurities and classifying grains by size.

Purifies and Classifies Semolina and Bran

The İRMİK SASÖRÜ, offered by Uğur Promilling, is a semolina purifier designed for precise cleaning and classification in flour and semolina milling operations. It features an adjustable flow rate system and a unique distribution mechanism to ensure even product coverage across its sieves. Utilizing a 2 or 3-tier sieving process, it efficiently removes bran and other impurities through a uniform vacuum created by aerodynamic air channels and adjustable flaps. This equipment plays a critical role in producing high-quality semolina for end-products like pasta, couscous, and baked goods. Capable of continuous, automated operation, it seamlessly integrates into existing production lines in food and grain processing industries. Additionally, the İRMİK SASÖRÜ offers customization options and engineering support to meet specific operational needs.

Benefits

- Enhances product quality by ensuring precise separation and purification of semolina and bran.

- Increases production efficiency with continuous and automated operation.

- Optimizes energy use through aerodynamic air channels and adjustable flaps, minimizing operational costs.

- Reduces contamination risk with effective dust and bran removal.

- Customizable setup supports diverse milling requirements and product specifications.

- Applications

- Semolina, Flour, Bran, Milling

- End products

- Bran muffins, Biscuits, Bran bread, Bavarian cream, Semolina pasta, Whole grain bread, Cakes, Pastries, Couscous

- Steps before

- Grinding, Initial Cleaning, Dehulling

- Steps after

- Bran Separation, Grading, Packaging

- Input ingredients

- irmik, kepek, un

- Output ingredients

- arındırılmış irmik, kepek, tasnif edilmiş irmik

- Market info

- Flow Rate Adjustment

- Adjustable

- Screening Layers

- 2 or 3 layers

- Separation Method

- Vacuum-assisted

- Air Channel Type

- Aerodynamic

- Vacuum Level

- Uniform across screen

- Flow control

- Batch

- Cleaning method

- Vacuum

- Separation technology

- Aerodynamic vacuum channel

- Distribution mechanism

- Adjustable flow rate with uniform distribution

- Abrasion resistance

- Suitable for semolina

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- Suitable for semolina grain

- Discharge method

- Vacuum-assisted discharge

- Sieve layers

- 2 or 3 layers

- Control panel type

- PLC interface / touchscreen

- Airflow adjustment

- Adjustable via control panel

- Screen size

- 2-layer or 3-layer