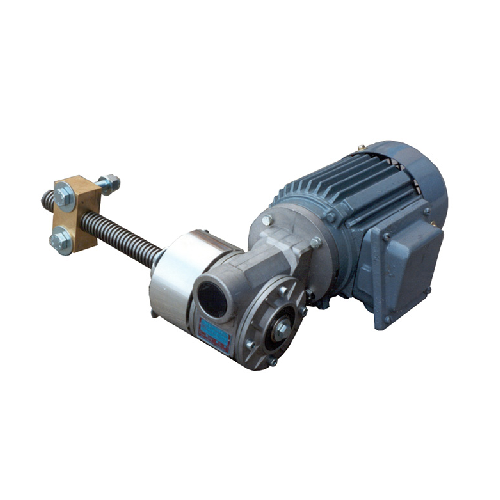

Electric gear motor actuators for slide valves

Achieve precise control over industrial slide valves in high-speed operations, ensuring seamless flow interruption and resumption in bulk solids handling and wastewater treatment processes.

Controls and Intercepts Bulk Solids Flow

The Electric Gear Motor Actuators CRG from WAMGROUP are designed to efficiently manage the flow of bulk solids through slide valves. These actuators enable precise opening and closing, making them vital for industries dealing with cement, grain, and industrial waste by-products. Featuring a robust and compact design, the CRG-type actuator integrates seamlessly with VLQ, VLC, VLR, and VDI slide valves. It operates with LSM 6-type limit switches, ensuring reliable performance in continuous and manual operations. Additionally, ATEX versions are available for use in hazardous environments. With a focus on versatility, these actuators are ideal for applications in environmental technology, building construction, and renewable energy sectors. The CRG actuators provide an energy-efficient solution by optimizing flow interception processes in processing and transport departments. Crafted for durability and ease of maintenance, they offer reliable performance and can be customized to suit specific industrial needs.

Benefits

- Enhances operational efficiency by ensuring precise flow control through robust actuator design.

- Minimizes energy consumption with optimized motor performance for sustainable operations.

- Supports seamless integration with existing WAMGROUP slide valves, reducing installation time.

- Offers versatility with ATEX compliance options for safe use in hazardous environments.

- Improves reliability by reducing the risk of downtime in continuous processing applications.

- Applications

- Valves, Mixers, Dust filtration, Bulk solids handling, Renewable energy, Screw conveyors, Biogas plant equipment, Environmental technology, Slide valves, Wastewater treatment, Industrial actuators

- End products

- Biomass pellets, Concrete mix, Wastewater sludge, Grain, Biogas, Food powders, Industrial dust particulates, Flour, Fertilizers, Silo-stored materials, Sand, Industrial chemicals, Industrial waste by-products, Gravel, Cement

- Steps before

- Material Preparation, Valve Configuration, System Integration

- Steps after

- Flow Interception, Valve Monitoring, System Maintenance

- Input ingredients

- Output ingredients

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Compatibility

- VLQ, VLC, VLR, VDI-type Slide Valves

- Limit Switch Requirement

- LSM 6-type mandatory

- ATEX Compliance

- Available upon request

- Design

- Sturdy, durable compact

- Interchangeability

- With other WAM Actuators

- Automation level

- Manual / PLC / SCADA

- ATEX Versions

- Available on request

- Interchangeability

- Compatible with multiple WAM valves

- Compact Design

- Sturdy and durable

- Limit Switch Integration

- LSM 6-type mandatory

- Opening and Closing Mechanism

- Electric Gear Motor

- Slide Valve Compatibility

- VLQ, VLC, VLR, VDI-type

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Sturdy, durable compact design

- Interchangeability

- Interchangeable with other WAM Actuators

- Actuation type

- Electric Gear Motor

- ATEX versions

- Available on request

- Interchangeability

- Interchangeable with other WAM Actuators