Coriolis mass flow meter for powdered materials

Achieve precise continuous feeding and control of bulk solids like cement and fertilizers with unparalleled accuracy in dynamic production environments.

Accurately Measures and Controls Bulk Material Flow

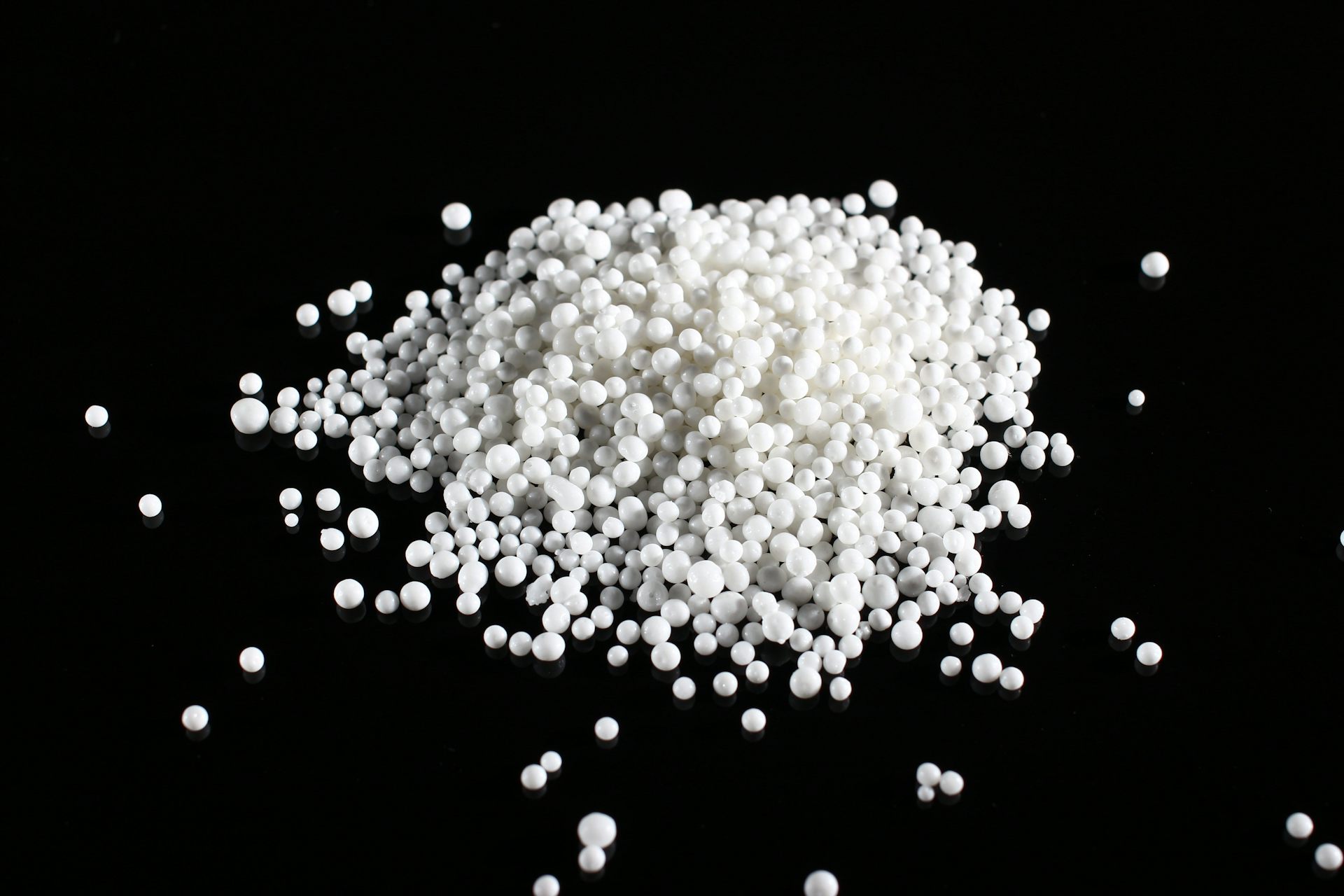

The MULTICOR H from Schenck Process is a highly precise Coriolis mass flow meter designed for the continuous feeding and measurement of bulk solids like powdered materials, dusts, and meals. Operating on the Coriolis principle, it offers accurate mass flow-rate readings by tracking the effect of bulk solids on a rotating measuring wheel. This technology ensures consistent feeding performance across diverse applications, including cement production, steelmaking, and agricultural processing. The MULTICOR H is compact and easy to integrate into existing production lines, minimizing setup costs. Its ability to handle varying bulk densities and grain sizes with an accuracy of ±0.5% makes it indispensable for producers of Portland cement, iron ore pellets, and fertilizers. The in-line design simplifies installation and reduces maintenance needs. Available with customizable prefeder controls, the unit enhances operational efficiency without sensitivity to external conditions.

Benefits

- Enhances production efficiency with precise mass flow-rate control.

- Reduces operational costs through easy in-line installation and low maintenance.

- Provides flexibility in handling diverse materials, ensuring accuracy despite varying densities.

- Minimizes material waste with consistent, reliable feeding accuracy.

- Integrates seamlessly into existing systems, optimizing overall production processes.

- Applications

- Powdered materials, Dust, Agrichemicals, Bulk solids, Flour, Meal, Steelmaking, Fertilizers, Cement

- End products

- Gypsum dust, Ammonium nitrate, Catalyst powders, Wheat flour, Pvc powder, Portland cement, Urea granules, Iron ore pellets, Limestone powder, Soybean meal

- Steps before

- Grinding, Mixing, Drying

- Steps after

- Packing, Quality Control, Transport

- Input ingredients

- bulk solids, powdered materials, meal, dust, flour, changing bulk density, different grain size

- Output ingredients

- precise feeding, material stream measurement, throughput measurement, consumption measurement, in-plant inventory measurement, return measurement in mills, material charging in processes, optimization of truck loading

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Accuracy

- ±0.5%

- Installation type

- In-line

- Control system

- DISOCONT® Tersus

- Feed rate control

- Coriolis principle

- Material compatibility

- Powdered materials and meal

- Compact construction

- Yes

- Working mechanism

- Coriolis force principle

- Flow operation

- Continuous

- Installation type

- In-line

- Compact construction

- True

- Effect of material properties

- Insensitive to bulk density changes

- Automation level

- Adjustable prefeeder integration

- Density/particle size

- Adaptable for varying densities and grain sizes

- Material density variation

- Handles varied densities

- Compact footprint

- Extremely compact construction

- Installation

- In-line implementation

- Maintenance

- Low maintenance and repair costs

- Discharge method

- Adjustable prefeeder

- Compact footprint

- Yes

- Control panel type

- Digital display

- Integration possibilities

- Seamless with existing systems

- Maintenance access

- Easy access panels