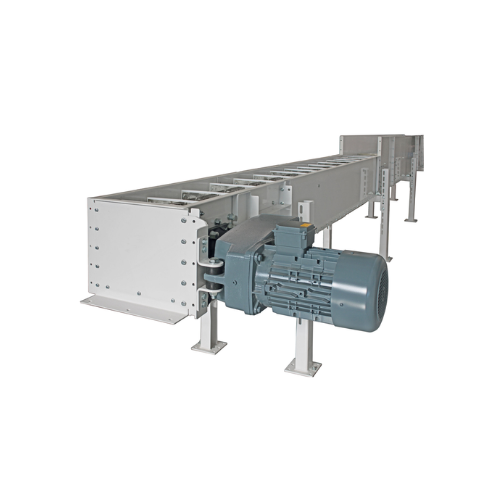

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, contamination-free transportation of materials, enhancing hygiene and operational reliability in food processing and grain handling.

Conveys and Sorts Grain and Food Products

The Chain Conveyor LBCB from Bühler Group is engineered to streamline the movement of bulk grains and food products, offering high customization to meet specific processing needs. Utilizing a bottom-up design approach, each conveyor can be tailored to fit unique operational requirements in food processing and agricultural industries. The LBCB enhances sanitation through plastic scrapers on each link and rubber cleaning vanes, minimizing product retention and meeting stringent hygiene standards. It efficiently handles a variety of products, from barley malt and ground coffee to white rice and spaghetti. The system is modular, allowing easy integration into existing lines, with capacities adaptable to throughput needs. Its zero-motion monitor and durable construction enhance reliability while noise-reducing features like the return rail ensure a quieter operation environment. Available in robust materials for longevity, it supports continuous operations with minimal maintenance, making it an ideal choice for production facilities seeking efficiency and high operational uptime.

Benefits

- Enhances hygiene and minimizes contamination with advanced cleaning features.

- Offers high customization for specific production needs, improving process adaptability.

- Reduces operational noise by up to 50%, creating a quieter work environment.

- Ensures reliable operation with safety features like zero-motion monitoring.

- Lowers maintenance costs through durable construction and materials.

- Applications

- Animal feed, Baked goods, Wheat, Snacks, Pasta, Paddy, Confectionery, Pulses, Grain, Brewing, Coffee, Oilseeds, Flour, Spices, Rice, Dairy

- End products

- Barley malt, Spaghetti, Ground cumin, Sunflower oil, Brown rice, Potato chips, Chocolate bars, White rice, Milk powder, Animal feed pellets, Lentil soup, Whole grain muffins, Ground coffee, Whole wheat bread

- Steps before

- Conditioning, Dehulling, Grain handling, Malting, Milling, Extrusion

- Steps after

- Sifting, grading, Packing, Palletizing, Refining

- Input ingredients

- grain, floury products, coffee, wheat, rice, paddy

- Output ingredients

- conveyed grain, conveyed floury products, processed coffee, processed wheat, processed rice, processed paddy

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Versatility

- Bottom-up design customization

- Sanitation Features

- Plastic scrapers and rubber cleaning vanes

- Operational Reliability

- Zero-motion monitor and overflow flap

- Material

- Superior-quality steel

- Noise Reduction

- Up to 50% via return rail

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / Manual

- Versatility

- Configurable

- Operational reliability

- High

- Abrasion resistance

- Steel construction

- Cleanability

- Plastic scrapers and rubber cleaning vanes

- Corrosive resistance (e.g. acids)

- Superior-quality steel

- Density/particle size

- Handles grainy and floury products

- Machine footprint

- Compact design

- Material of construction

- Superior-quality steel

- Configuration

- Modular design

- Discharge method

- Bottom discharge via outlet flaps

- Control panel type

- PLC-controlled

- Cleanability

- Easy to clean design

- Chain options

- Multiple chain options available

- Bearing options

- Diverse bearing options available

- Configuration flexibility

- Modular and customizable

- Conveyor accessories

- Wide range of accessories

- Plate link scrapers

- Plastic scrapers on every link

- Cleaning vanes

- Special rubber cleaning vanes