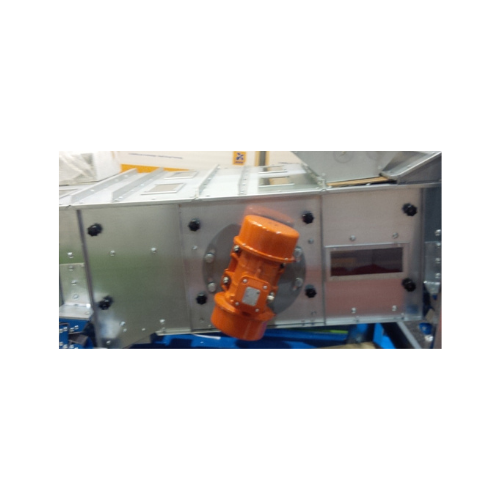

Electric motovibrators for flour milling sieving

Enhance precision in your milling operations with motovibrators that deliver optimal sieving performance, ensuring efficient separation and classification of various grain components.

Facilitates Vibration and Sieving for Grain Processing

The MVE-Milling external electric motovibrators from WAMGROUP are engineered to optimize the sieving process in flour milling and grain processing industries. These vibrators are integral to achieving precise separation and classification, leveraging a dual-vibrator setup that exploits linear centrifugal force for enhanced accuracy. Capable of delivering 1,200 or 1,400 kg of centrifugal force with 8 or 10 pole motors, they are designed for continuous high-speed operations. Their sturdy FMEA-designed cast casing encompasses vacuum-impregnated windings and oversized roller bearings, ensuring durability and reliability even under demanding conditions. ATEX ExII3D certified, the MVE-Milling motovibrators are suitable for operations in hazardous environments where flammable dust may be present. Customizable voltage options ensure global electric specification compatibility, while their compact design allows integration into confined spaces, making them ideal for various food, grain, and animal feed applications.

Benefits

- Enhances precision in separation, ensuring higher product quality.

- Operates reliably in hazardous environments, maintaining safety standards.

- Minimizes maintenance needs with durable oversized bearings.

- Allows seamless integration into existing systems with a compact design.

- Adapts to global power requirements with multiple voltage configurations.

- Applications

- Animal feed, Food additives, Grain, Flour, Rice

- End products

- Polished rice, Flavor enhancers, Rye grain, Pasta flour, Semolina, Barley grain, Emulsifiers, Bread flour, Cornmeal, Brown rice, Poultry feed, Cattle feed, Wheat grain, Fish meal, Vitamin premixes

- Steps before

- Purification, Cleaning, Grinding

- Steps after

- Classification, Packaging, Quality Control

- Input ingredients

- grain components, flour, potentially flammable dusts

- Output ingredients

- finely separated grain components, classified grain components

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Centrifugal force

- 1, 200 or 1, 400 kg

- Motor poles

- 8 or 10 poles

- ATEX certification

- ExII3D

- Insulation class

- Class F

- Bearing type

- Oversized roller bearings

- Vibration frequency

- Low frequency

- Vibration amplitude

- High amplitude

- Poles in motor

- 8 or 10 poles

- Installation method

- Mounted in parallel

- Force type

- Linear centrifugal force

- Certification

- ATEX ExII3D

- Application type

- Sieving machines for flour milling

- Operation environment

- Hazardous environments

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sieving machine application

- Flour milling

- Use in hazardous environments

- Flammable dust presence

- ATEX certification

- ExII3D

- Centrifugal force

- 1, 200 or 1, 400 kg

- Motor

- Electric motor with sturdy FMEA-designed casing

- Bearings

- Oversized roller bearings