Integrated grinder for wheat and grain

Achieve superior grinding performance and energy efficiency with this fully integrated system, designed to optimize product distribution and energy recovery while ensuring food safety through residue-free cleaning and precise temperature monitoring. Ideal for streamlining operations and reducing costs in your production line.

Grinds and Homogenizes Grains and Feed

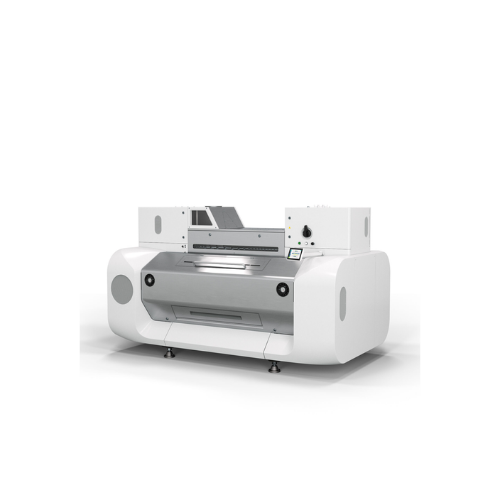

The Arrius MRRA from Bühler Group is a revolutionary integrated grinding system that offers seamless operation for flour mills and food processing industries. This system sets itself apart with fully integrated components, including a pre-stressed, backlash-free roller pack and an asymmetrical feed module, ensuring homogenous product distribution across the roller length. Capable of processing a range of grains, such as wheat, corn, and barley, the Arrius delivers high-quality end-products like whole wheat flour, semolina, and cornmeal with exceptional precision.

Designed for high throughput, the Arrius operates continuously and can be monitored via remote devices using an integrated web server. It includes advanced automation features, such as roller temperature measurement and motor-driven grinding gap adjusters, ensuring optimal performance and exceptional energy efficiency—saving up to 10% in energy consumption. Constructed with food-grade stainless steel materials, the system adheres to stringent food safety protocols, featuring a hygienic design that allows complete cleaning under the machine.

With modular options including four-roller and eight-roller versions, and roller lengths ranging from 1000 to 1500 mm, the Arrius can be tailored to specific operational needs. Its “plug-and-play” design enables quick installation and integration into existing production lines, while maintenance is streamlined with the ability to change the roller pack in under an hour. Bühler provides comprehensive engineering support, including process optimization and training, ensuring that the Arrius MRRA elevates your grinding operations to new standards of efficiency and quality.

Benefits

- Optimizes energy usage, reducing costs by up to 10%.

- Enhances product consistency and quality through even product distribution.

- Minimizes infrastructure investment by eliminating the need for additional floors.

- Improves operational safety with advanced sensor technologies and lockable covers.

- Streamlines maintenance with easy roller pack changes, boosting productivity.

- Applications

- Animal feed, Spelt, Durum wheat, Oats, Wheat, Sorghum, Snacks, Baked goods, Confectionery, Pasta, Pet food, Paddy, Starch, Rice, Corn, Rye, Barley

- End products

- Biscuits, Whole wheat flour, Starch powder, Dog kibble, Pasta noodles, Sorghum flour, Oat flour, Jasmine rice, Caramel candies, Cornmeal, Rye flour, Durum semolina, Malted barley, Compound animal feed pellets, Bread loaves, Spelt flour, Chocolate bars, Cat biscuits, Basmati rice

- Steps before

- Dehulling, Pre-cleaning, Conditioning

- Steps after

- Sifting, Grading, Packing

- Input ingredients

- wheat, durum wheat, rye, barley, corn, spelt, starch, sorghum, oats

- Output ingredients

- ground wheat, ground durum wheat, ground rye, ground barley, ground corn, ground spelt, processed starch, ground sorghum, ground oats

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- {{"Technical Specification","Grinding Performance","Unparalleled stability"},{"Technical Specification","Energy Efficiency","Up to 10% energy saving"},{"Technical Specification","Roller Length","1000 mm,1250 mm,1500 mm"},{"Technical Specification","Roller Configuration","Four-roller and eight-roller"},{"Technical Specification","Drive System","Integrated motor and gearbox"},{"Technical Specification",Automation,"PLC-controlled with remote app control"},{"Technical Specification","Food Safety","Stainless steel and food-grade materials"},{"Technical Specification","Installation Time","Reduced with plug-and-play design"},{"Technical Specification","Maintenance Time","Roller change in less than an hour"},{"Technical Specification","Sensor Technology","Roller temperature measurement"}}

- Operating mechanism

- Integrated grinding system

- Energy efficiency

- 10% energy savings

- Automation level

- PLC / SCADA

- Cleaning method

- Manual / Hygienic design

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- < 1 hour for roller pack

- Plug-and-play design

- Fast installation

- {{"Material Compatibility","Abrasion resistance",Yes},{"Material Compatibility","Biological compatibility","Food-grade materials"},{"Material Compatibility",Cleanability,"Stainless steel surfaces"},{"Material Compatibility","Corrosive resistance (e.g. acids)","Stainless steel construction"}}

- Grinding Performance

- Durum, wheat, rye

- Machine footprint

- Compact design, saves floor space

- Roller lengths

- 1000 mm, 1250 mm, 1500 mm

- Roller versions

- Four-roller, eight-roller

- Discharge method

- Residue-free discharge with emptying function

- Control panel type

- Integrated web server for remote operation

- Hygienic design

- Stainless steel, food-grade materials

- Control panel type

- Integrated web server

- Integration possibilities

- Remote app connectivity

- Roller configuration

- Four-roller / Eight-roller

- Roller length options

- 1000 mm / 1250 mm / 1500 mm