Flour sifting and sorting solution for grain mills

Optimize your milling operations with efficient sifting and sorting technology designed to maximize throughput while ensuring product consistency and quality in flour production.

Sifts and Sorts Flour and Grain

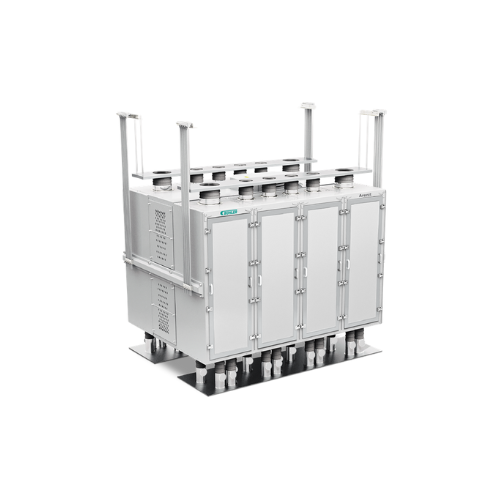

The Arenit Plansifter MPAV/W from Bühler Group is a robust solution tailored for flour mills and grain processing applications. Featuring a compact and efficient design, this plansifter excels in effectively sifting and sorting a variety of products including white bread flour, cornmeal, and durum semolina. Its high throughput capability is supported by a net sieve surface of up to 84 m² and the inclusion of up to 26 Nova sieve compartments, enabling seamless integration into both new and existing production lines.

The Arenit uses a stable cast metal frame for continuous, 24/7 operation, ensuring durability and reliability in demanding environments. Available with wooden or synthetic sieve frames, the machine supports enhanced food safety through stainless steel lining and insulated sifter compartments, which prevent condensation and product damage.

Designed for energy efficiency, the Arenit employs a lightweight motor with adjustable swing weight settings to minimize power consumption. The inclusion of a NovaTens sieve tensioner further ensures even tension across sieves, improving operational consistency. With options for customization and Bühler’s engineering support, the Arenit accommodates specific operational needs, making it a versatile asset in wheat, rye, corn, and durum processing for the production of diverse flour and grain products.

Benefits

- Maximizes throughput in limited space with compact design and large sieve surface area.

- Enhances operator safety and product quality by preventing contamination with sealed and insulated compartments.

- Lowers operational costs with energy-efficient lightweight motor and adjustable swing weight.

- Supports continuous 24/7 operation with a sturdy cast frame and reliable componentry.

- Streamlines maintenance with robust sieve tensioning system, reducing service interruptions.

- Applications

- Durum, Wheat, Grist, Grain processing, Flour, Flour milling, Corn, Rye

- End products

- Polenta, Rye bread flour, Whole wheat flour, Durum semolina, All-purpose flour, White bread flour, Cornmeal, Bran flakes

- Steps before

- Dehulling, Milling, Grinding, Flaking, Conditioning

- Steps after

- Packing, Palletizing, Sorting, Weighing, Dosing

- Input ingredients

- wheat, rye, corn, durum

- Output ingredients

- grist, flour, floury products, granular products

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Sifting surface area

- Up to 84 m²

- Sieve compartments

- Up to 26 Nova sieve compartments

- Frame material

- Cast metal

- Operation

- 24/7 operation

- Sieve type

- Wooden or synthetic sieve frames

- Sieve dimension

- 730 mm x 730 mm

- Energy efficiency

- Lightweight motor

- Sieve cleaning

- Efficient sieve cleaning

- Sanitation level

- High

- Sieve tensioning

- NovaTens sieve tensioner

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick integration

- Cleaning method

- Efficient cleaning

- Energy efficiency

- Lightweight motor

- Sifting capacity

- 84 m² sieve surface

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Net sieve surface

- Up to 84 m²

- Sieve compartments

- Up to 26 Nova compartments

- Frame material

- Cast metal

- Sieve stack material

- Wooden or synthetic (NovaTec)

- Sieve size

- 730 mm x 730 mm (NovaTec)

- Sieve tensioner type

- NovaTens

- Control panel type

- 0

- Discharge method

- 0

- Sieve frame material

- Wooden / Synthetic

- Motor weight adjustment

- Customizable swing weight

- Sieve tensioning

- NovaTens sieve tensioner

- Sieve stack size

- Up to 26 Nova sieve compartments

- Footprint design

- Compact for new plants/retrofits