Online color and specks measurement for milling processes

Ensure your milling process consistently delivers top-quality flour and semolina by performing real-time monitoring and analysis of color and specks, eliminating the need for lab tests and allowing immediate production adjustments.

Monitors and Analyzes Color and Specks in Real-Time

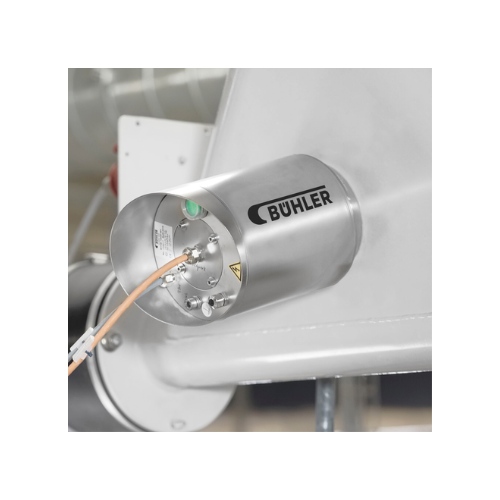

The Online Color and Specks Measurement Unit MYHB from Bühler Group revolutionizes quality control in milling processes through real-time, continuous monitoring. This unit features a high-resolution camera that detects subtle color deviations and classifies specks down to 80 micrometers in size, ensuring consistent quality for flour and semolina. By eliminating traditional lab tests, it enhances transparency and traceability, catering to milling companies and food processing plants. The MYHB integrates seamlessly into existing milling operations, is compact for easy installation, and can be paired with Bühler’s NIR Multi Online Analyzer for comprehensive analysis of moisture, protein, and other critical parameters. Adjustable via PLC controls for optimal integration, it supports operational efficiency by providing on-the-fly adjustments to the milling process, thereby maintaining product quality and reducing waste.

Benefits

- Enhances product consistency by providing real-time color and specks analysis.

- Increases efficiency by eliminating the need for subjective and time-consuming lab tests.

- Boosts transparency and traceability with detailed online documentation for quick access during recalls.

- Integrates seamlessly into existing milling setups, minimizing installation disruptions.

- Supports quick process adjustments, reducing waste and improving overall production quality.

- Applications

- Grains, Wheat, Semolina, Grain products, Flour, Milling products

- End products

- Whole grain flour, Durum semolina, All-purpose flour, Pastry flour, Cake flour, Wheat flour, Bread flour, Semolina flour, Couscous

- Steps before

- Milling, Grinding, Semolina production

- Steps after

- Packing, Palletizing

- Input ingredients

- flour, semolina, grains

- Output ingredients

- consistently colored flour, consistently colored semolina, reduced specks in end product

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Accuracy

- Detection of subtle color deviations

- Automation

- Real-time monitoring and adjustments

- Resolution

- High-resolution camera

- Detection type

- Color and specks monitoring

- Response time

- Instant/Real-time

- Speck detection size

- 80 micrometers and above

- Color spectrum measurement

- CIE color spectrum, L*a*b*

- Data storage

- Online documentation and tracking

- Automation level

- Continuous real-time monitoring

- Batch vs. continuous operation

- Inline Continuous

- Real-time analysis

- Color and specks in flour and semolina

- Data documentation

- Online storage for transparency and traceability

- Adjustment capability

- Automatic production process adjustments

- Integration capability

- Retrofitting existing milling systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact design

- Easily fitted into existing milling components

- Integration capabilities

- Compatible with gravity spouts, scales, retarding sections

- Compatibility with analyzers

- Can be combined with NIR Multi Online Analyzer