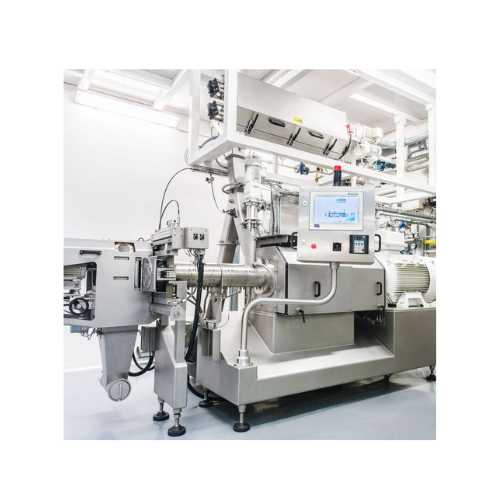

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion technology, designed for seamless integration into continuous production lines to handle diverse food and material applications.

Processes and Extrudes Diverse Food and Feed Products

The PolyTwin, EcoTwin, and CompacTwin twin-screw extruders from Bühler are designed for versatile applications across food and feed industries. They are engineered to handle complex extrusion processes, using high torque and variable screw speeds to customize production, catering to products like breakfast cereals, pet food, and alternative proteins. These extruders feature a modular design, enabling seamless integration into existing production lines with continuous, fully automatic operations. With a focus on operational efficiency, the machine’s barrel is resistant to wear, reducing maintenance needs and prolonging life. Equipped with intelligent recipe memory, these extruders ensure consistent end-product quality and enable swift recipe changes, minimizing downtime. Available with a robust screw ejection unit and adjustable cutter, cleaning and maintenance become more manageable, enhancing overall productivity. Bühler’s support extends to customization and engineering assistance, making these machines adaptable to specific customer requirements.

Benefits

- Enhances production flexibility with customizable process configurations.

- Prolongs equipment lifespan with wear-resistant barrel technology.

- Minimizes downtime through fast, automated recipe changes and screw ejection.

- Ensures consistent product quality with intelligent process control and memory.

- Streamlines maintenance with easy access for cleaning and component adjustments.

- Applications

- Snacks, Grain, Cosmetics, Chocolate, Dairy, Chemicals, Biorefinery, Printing inks, Pulses, Paddy, Spices, Aqua feed, Breakfast cereals, Batteries, Cocoa, Animal feed, Alternative proteins, Pasta, Pet food, Nuts, Food ingredients, Rice, Paints, Dried fruits, Electronic materials, Baked goods, Insect technology, Oilseeds, Wheat, Confectionery, Digital inks, Coatings, Vegetables

- End products

- Dog kibble, Lithium-ion battery components, Wheat flour, Potato chips, Peanut butter, Raisin snacks, Popcorn, Foundation creams, Automotive paints, Circuit board laminates, Whole wheat bread, Protein bars, Jasmine rice, Chicken feed, Cocoa powder, Oat milk, Almond milk, Soy chunks, Hazelnut spread, Cornflakes, Lentil pasta, Cat food, Granola, Plant-based meat, Dried apple slices, Almond flour, Muesli base flakes, Conductive inks, Gummy bears, Sunflower oil, Polyurethane foam, Uv-cured coatings, Shrimp feed, Pig feed, Chocolate bars, Rice noodles, Savory biscuits, Fish feed pellets, Magazine printing inks, Lipsticks

- Steps before

- Ingredient handling, Mixing, Preconditioning, Grain handling, Dehulling

- Steps after

- Cooling, Cutting, Sifting, grading, Packing, Palletizing, Pelleting

- Input ingredients

- breakfast cereals ingredients, food ingredients, pet food ingredients, aqua feed ingredients, raw materials for extrusion

- Output ingredients

- breakfast cereals, finished food ingredients, pet food, aqua feed

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Operation mode

- 24/7 continuous

- Torque

- High torque

- Screw speed

- Variable

- Pressure capability

- Variable

- Barrel wear resistance

- High resistance

- Screw ejection unit

- Fully automatic

- Cutter flexibility

- Adjustable during operation

- Preconditioner stages

- Two-stage

- End-product quality consistency

- High

- Working mechanism

- Twin-screw extrusion

- Integrated steps

- Mixing, cooking, forming

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Batch vs. continuous operation

- Continuous

- Changeover time

- Rapid changeover capability

- Cleaning method

- Manual / CIP

- Energy efficiency

- Low-energy operation

- Abrasion resistance

- High

- Biological compatibility

- Food-grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Moderate

- Density/particle size

- Adaptable for various densities

- Machine Footprint

- Compact design

- Barrel Interior

- Extremely resistant to wear

- Compact Footprint

- Yes

- Modular design

- Allows customization for different applications

- Control panel type

- Intelligent recipe memory

- Screw ejection unit

- Patented, fully automatic