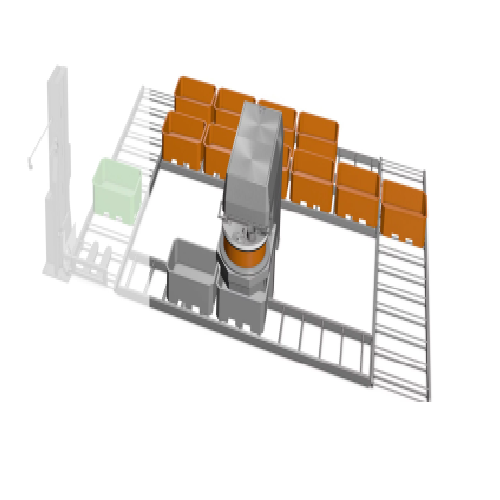

Mixing system for long dough resting times

Achieve consistent dough quality with extended resting times, optimizing water absorption and air incorporation to elevate your artisan bread production.

Mixes, Rests, and Transports Dough

The POWER SQUARE SYSTEM from WP Kemper is an engineered solution tailored for industrial bakeries requiring precise control over dough preparation for extended resting times. Featuring the KEMPER 3-zone mixing principle, it ensures airy doughs with high water absorption and consistent quality. This system automates the entire dough handling process—from mixing and resting to transporting and discharging. Available in multiple configurations, such as the POWER SQUARE SYSTEM 18×1, 32×2, and 46×3, it accommodates varying production capacities, up to 7,200 kg of dough per hour. The robust design integrates seamlessly into existing production lines, featuring stainless-steel spirals, guide bars, and automated container transport. The touch panel interface allows for process visualization, while options for customized raw material supply and superordinate control system interfaces enhance flexibility and integration. With a focus on reducing downtime, the system’s monitoring facilitates proactive maintenance, ensuring reliable operations for producing a wide range of products, including artisan breads and specialty rolls.

Benefits

- Ensures consistent dough quality with high water absorption through the KEMPER 3-zone mixing principle.

- Minimizes production downtime with automated dough handling and integrated monitoring systems.

- Accommodates high-volume production with capacities up to 7,200 kg per hour.

- Enhances operational efficiency with rapid ingredient mixing and short cycle times.

- Offers flexibility with customizable integration options for existing control systems.

- Applications

- Mixed wheat dough, Wheat dough, Bakery products, Bread dough

- End products

- Baguettes, Rye bread, Specialty bread rolls, Artisan breads, Mixed grain loaves, Soft rolls, Sourdough loaves, Ciabatta, Brioche, Whole wheat bread, Focaccia

- Steps before

- Ingredient mixing, Automatic raw material supply, Dough preparation

- Steps after

- Bowl tipping, Packing, Quality inspection

- Input ingredients

- soft dough, wheat dough, mixed wheat dough, raw materials

- Output ingredients

- airy dough, dough with high water absorption, processed dough, fully mixed dough

- Market info

- WP Kemper is known for manufacturing high-quality industrial baking equipment, specializing in mixing, dividing, and dough processing solutions, with a strong reputation for innovation, engineering excellence, and reliable service in the bakery industry.

- Automation

- Fully automatic

- Mixing capacity

- Up to 7, 200 kg dough/hour

- Cycle time

- 3.3 minutes

- Dough resting time

- 240 minutes

- Dough resting positions

- 8 - 36

- Dough discharge method

- Large base discharge opening

- Mixing principle

- KEMPER 3-zone mixing

- Spiral mixer type

- Single or double spiral made of stainless steel

- Guide bar material

- Stainless steel

- Container transport system

- Chain transport system

- Bowl material

- Stainless steel

- Container type

- Square, blue plastic containers

- Bowl diameter base opening

- Large diameter

- Layout customization

- Automatic raw material supply connections

- Interface

- Prepared for superordinate control system

- Portioning hopper

- Available

- Access control

- KEMPER KEY

- Working mechanism

- Mixing and dough resting

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Dough Type

- Very soft doughs

- Dough Resting Duration

- Particularly long

- Capacity

- Up to 7, 200 kg dough/hour

- Mixing Principle

- 3-zone mixing principle

- Container Material

- Blue plastic containers

- Machine footprint

- Modular and adaptable

- Discharge method

- Large base discharge opening

- Container type

- Square, blue plastic containers

- Control panel type

- Touch panel with menu navigation

- Protective enclosure

- All-round protective enclosure with limit switch protected doors

- Bowl type

- Fixed bowl made of stainless steel

- Bowl wall scraper

- Can be folded down for cleaning

- Diameter of base opening

- Large diameter for quick discharge

- Bowl cover

- Incl. safety ring with a protective switch

- Bowl tipper

- HK 200, space-saving column design

- Control panel type

- Touch panel with menu navigation and process visualization

- Discharge method

- Large diameter base opening for quick dough discharge

- Bowl type

- Fixed bowl made of stainless steel with a large diameter base opening

- Guide bar material

- Stainless steel

- Spiral type

- Single or double spiral made of stainless steel

- Container type

- Square, blue plastic dough resting containers