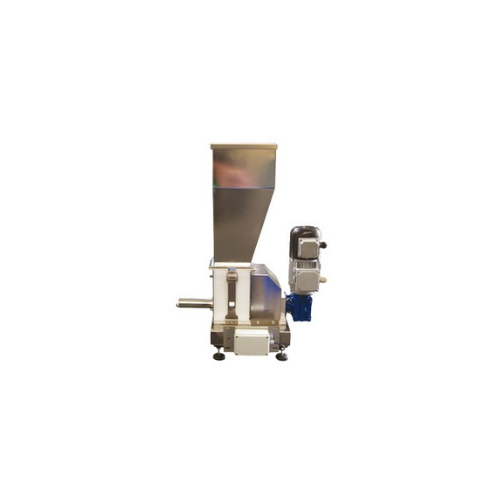

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced screw feeder, ideal for managing powders and granules in demanding production environments where accuracy and consistency are crucial to maintaining product quality.

Accurately Meters and Feeds Powders and Granules

The DCC Loss-In-Weight Screw Feeders from WAMGROUP ensure precise metering and feeding of powders and granules, catering to diverse industries such as food, cosmetics, and chemicals. Featuring a micro-screw feeder within a food-grade polymer body, these feeders are enhanced with stainless steel guards for durability. The system utilizes load cells for accurate weight measurements, facilitating continuous processing with high precision. Suitable for applications from biscuit processing to pharmaceuticals manufacturing, it efficiently handles products like wheat flour, dog biscuits, and acrylic paint. Customization includes variable speed drives for process optimization. The feeder’s design allows for easy dismantling and cleaning, while its non-stick body promotes seamless material flow. Compliant with industry standards, this feeder can be equipped with optional scale pans, ensuring integration into various production lines.

Benefits

- Enhances operational precision with accurate dosing and metering capabilities.

- Minimizes contamination risk through easy dismantling and cleaning processes.

- Adapts to diverse production needs with customizable speed drives.

- Supports seamless integration into existing production lines with load cell-equipped design.

- Complies with food-grade and industrial standards for versatile applications.

- Applications

- Biscuit processing, Cosmetics, Bakery plants, Packaging plants, Animal feed milling, Beverage processing, Detergents, Noodle making, Flour milling, Chocolate processing, Spices, Resin, Cocoa, Pasta, Convenience food, Varnish, Mixing plants, Dosing plants, Pharmaceuticals, Bakeries, Paint, Salt processing

- End products

- Dog biscuits, Vitamin tablets, Wheat flour, Adhesive resin, Cattle feed, Beer, Macarons, Curry powder, Wood varnish, Chicken feed, Cocoa powder, Lithium-ion battery components, Croissants, Corn flour, Soda, Liquid detergent, Ramen noodles, Acrylic paint, Instant soup, Facial cream, Table salt, Chocolate bars

- Steps before

- Grinding, Mixing, Material Handling, Pre-weighing

- Steps after

- Packing, Packaging, Quality Control, Storage

- Input ingredients

- powders, granular materials, flour, animal feed additives, biscuit ingredients, pasta ingredients, noodle ingredients, bakery ingredients, cocoa, chocolate, salt, convenience food ingredients, spices, detergents, soap, cosmetics, pharmaceuticals, paint, varnish, resin

- Output ingredients

- precisely metered powder, precisely metered granules, metered animal feed additives, metered biscuit ingredients, metered pasta ingredients, metered noodles, metered bakery ingredients, metered cocoa, metered chocolate, metered salt, metered convenience foods, metered spices, metered detergents, metered soap, metered cosmetics, metered pharmaceuticals, metered paint, metered varnish, metered resin

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Accuracy

- High metering accuracy

- Material flow

- Free material flow

- Cleaning method

- Easy to clean

- Dosing type

- Continuous

- Feeder type

- Loss-In-Weight Screw Feeder

- Body material

- Food-grade synthetic material

- Contact parts material

- Stainless steel

- Drive

- Variable speed drive on request

- Scale type

- Optional electronically operated scale pan

- Automation level

- PLC-controlled / Manual

- Batch vs. continuous operation

- Batch / Continuous

- Cleaning method

- Easy to disassemble for cleaning

- Changeover time

- Quick changeover for different materials

- Cleanability

- Easy to clean

- Biological compatibility

- Food-grade materials

- Density/particle size

- Adaptable to powder and granules

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Machine footprint

- Compact

- Material

- Stainless steel / Food-grade polymer

- Body type

- Polymer-cast single piece

- Discharge method

- Screw feeder

- Feed method

- Continuous feed

- Control panel type

- Optional electronically operated

- Control panel type

- HMI touch screen / PLC interface

- Integration possibilities

- SCADA / ERP systems

- Variable speed drive

- Option available

- Scale pan option

- Mounted on load cells

- Outlet shut-off slide valve

- Available