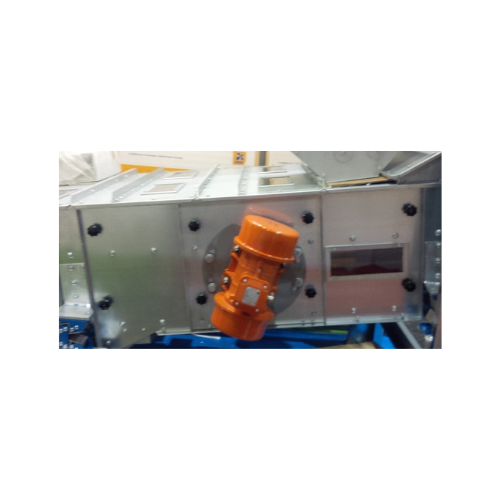

External electric motovibrators for efficient flour sieving

Optimize material flow in your milling operations with precision-driven motovibrators, ensuring consistent sieving and classification of grains and feed for high-quality end-products.

Enhances Sieving and Separation Efficiency

The MVE-Milling from WAMGROUP is an external electric motovibrator specially crafted for flour and feed milling industries, enhancing the sieving process by evenly distributing high centrifugal force. Delivering 1,200 or 1,400 kg of force with 8 or 10 poles, these units are integral to sieving machines for precise separation of grain components into wheat flour, cornmeal, and bran, among others. They feature oversized roller bearings encased in a robust, FMEA-designed structure, ensuring durability for heavy-duty operations and confined installations. The MVE-Milling is ATEX ExII3D certified for safe use in potentially explosive environments, with vacuum-impregnated Class F windings for thermal protection, while supporting multiple voltage configurations to suit global electrical standards.

Benefits

- Enhances sieving precision, leading to higher product quality and consistency.

- Operates safely in hazardous environments with ATEX certification.

- Reduces maintenance needs with durable, oversized roller bearings.

- Adapts to global use through versatile voltage compatibility.

- Saves space with high centrifugal force-to-size ratio for compact installations.

- Applications

- Animal feed, Food additives, Grain, Flour, Rice

- End products

- Bran cereals, Poultry feed mix, Swine feed formula, Wheat flour, Bread flour, Cornmeal, Rice flour, Cattle feed pellets, Vitamin-enriched premixes, Fortified rice

- Steps before

- Cleaning, Sorting, Pre-processing

- Steps after

- Packing, Quality Checking, Storage

- Input ingredients

- grain components, material for sieving, unprocessed flour

- Output ingredients

- separated grain components, classified material, processed flour

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Centrifugal force

- 1, 200 or 1, 400 kg

- Poles

- 8 or 10

- Motor type

- Electric

- Insulating material

- Class F

- Bearing type

- Oversized roller bearings

- Certification

- ATEX ExII3D

- Application

- Sieving machines

- Frequency range

- Low frequency high amplitude

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- High centrifugal force/size ratio

- Cleaning method

- Durable oversized bearings

- Centrifugal force

- 1, 200 or 1, 400 kg

- Hazardous environment suitability

- ATEX ExII3D certification

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ATEX certification

- ExII3D

- Casing design

- FMEA-designed cast casing