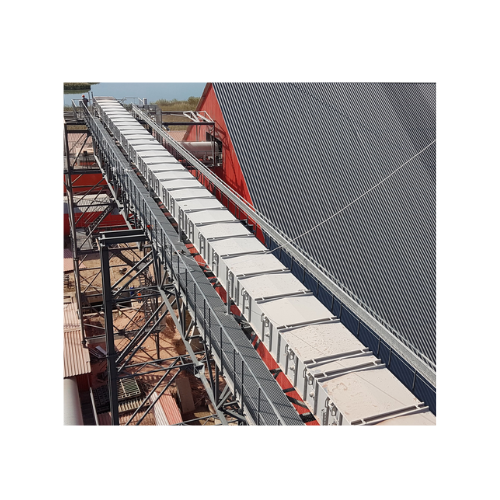

Enclosed belt conveyor for grain handling

Optimize your material transportation and ensure dust-free operations with this enclosed conveyor, designed for seamless grain and food product handling across your production line.

Conveys and Sorts Grain and Food Products

The Enclosed Belt Conveyor LBIA by Bühler Group is engineered for efficient grain and food product handling in various industrial applications. This fully enclosed system eliminates dust emissions and features a self-cleaning tensioning station, optimizing throughput between 350 to 2600 tons per hour. Specially designed idlers and a unique deflection station enable low energy consumption per ton, while maintaining operational safety through integrated monitoring devices. The conveyor’s modular design supports multiple inlets and outlets, even in inclined setups, offering maximum flexibility for food producers, feed manufacturers, and grain handling businesses. Available in configurations to cater to different processing needs, it enhances your production line by reducing maintenance downtime with quick-replace key components. Constructed to ensure hygiene standards, it is an ideal choice for operations requiring high-speed, continuous processing of solid and granular products with seamless integration into existing systems.

Benefits

- Reduces operational costs with low energy consumption per ton conveyed.

- Ensures dust-free operation through a fully enclosed design.

- Minimizes maintenance with quick-replacement parts for increased uptime.

- Enhances operational safety with built-in monitoring for early detection of potential issues.

- Offers flexible integration with modular construction for multiple inlet and outlet configurations.

- Applications

- Cocoa, Durum wheat, Wheat, Sorghum, Lentils, Beans, Nuts, Malting solutions, Seeds, Corn, Maize, Peas

- End products

- Cocoa powder, Pasta, Pea protein isolate, Lentil flour, Bean paste, Sorghum flour, Cornmeal, Flour, Sunflower seeds, Coconut flour, Malt extract, Cornflour, Almond flour

- Steps before

- Sorting, Cleaning, Dehulling, Milling, Grinding

- Steps after

- Packing, Palletizing, Processing, Weighing, Sifting

- Input ingredients

- wheat, cocoa, corn, maize, durum wheat, lentils, nuts, seeds, peas, sorghum, beans

- Output ingredients

- processed wheat, processed cocoa, processed corn, processed maize, processed durum wheat, processed lentils, processed nuts, processed seeds, processed peas, processed sorghum, processed beans

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Throughput

- 350 to 2600 tons per hour

- Design

- Completely enclosed

- Energy Consumption

- Low energy consumption per ton

- Flexibility

- Multiple inlets and intermediate outlets

- Monitoring Devices

- Belt misalignment, heat generation detection

- Replacement Time

- Quick replacement of key parts

- Dust Emission

- Completely eliminated

- Working mechanism

- Enclosed belt with self-cleaning tensioning station

- Energy efficiency

- Low energy consumption per ton of product conveyed

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Continuous

- Operational safety

- Multiple monitoring devices for safety

- Changeover time

- Quick replacement of key parts

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Modular construction

- Discharge method

- Multiple intermediate outlets

- Enclosure design

- Completely enclosed

- Construction material

- Hygienic design

- Modularity

- Fully modular construction

- Flexibility

- Multiple inlets and outlets

- Conveyor inlets

- Multiple

- Intermediate outlets

- Multiple

- Modular construction

- Yes

- Inclined conveyor system

- Yes

- Double outlet design

- Reduces height

- Self-cleaning tensioning station

- Yes

- Cage pulley

- Prevents product backup

- Lateral paddles

- Ensures material return

- Monitoring devices

- Belt misalignment and heat detection