Aeration pads for powdery material flow in silos

Ensure consistent material flow in your silos and bins with a reliable aeration solution that prevents common issues like rat-holing and bridging, optimizing discharge for powdery materials.

Enhances Material Flow and Prevents Discharge Issues

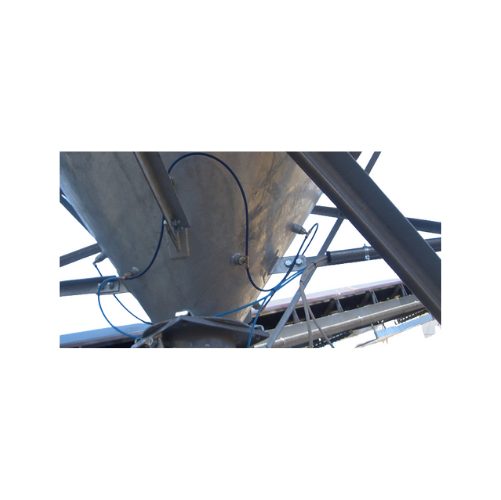

The Aeration Pads I100 from WAMGROUP provide an economical solution for enhancing material flow in silos and hoppers across multiple industries like cement, lime, and asphalt production. These pads prevent material flow issues such as bridging and rat-holing by using a durable polymer pad with a semi-convex design, enabling wide-angle air emission for effective aeration. Suitable for applications involving powdery and granular materials, they ensure smooth discharge and optimal material storage conditions.

Operating at 0.2 bar (3 PSI), the Aeration Pads I100 are effective in continuous and manual operations, facilitating integration in both retrofitting and new installations. Engineered for reliability, these pads include a self-cleaning, anti-clogging design and offer optional external mounting kits for easy installation in diverse setups like batching and dosing plants. Designed to function across a range of operational environments, these pads are ideal for silo manufacturers and producers in ready-mix concrete, precast concrete, and dry-mix building materials, among others.

Benefits

- Ensures consistent material discharge, reducing blockages and production delays.

- Low operating pressure minimizes energy usage, enhancing cost efficiency.

- Easy installation with retrofit capability, lowering setup time and costs.

- Durable polymer construction offers long-term reliability and reduced maintenance.

- Adaptable for various industries, broadening operational flexibility.

- Applications

- Lime, Marble, Asphalt, Construction ad-mixtures, Roofing materials, Powdery materials, Cement

- End products

- Marble dust, Asphalt paving mixtures, Roofing shingles, Cement bags, Lime powder, Concrete admixtures, Talcum powder

- Steps before

- material storage, material transport, silo loading, bin loading, hopper loading

- Steps after

- material discharge, material transport, batch processing, mixing, packaging

- Input ingredients

- powdery materials, cement, lime, material residues, entrained dust

- Output ingredients

- fluidized materials, air emissions

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Aeration rate

- Wide emission angle due to semi-convex shape

- Operating pressure

- 0.2 bar (3 PSI)

- Material flow facilitation

- Prevents rat-holing, bridging, segregation

- Design

- Self-cleaning, anti-clogging

- Mounting

- External mounting kit available

- Durability

- Lightweight, robust engineering polymer casing

- Application

- Single or multiple row installation

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- Self-cleaning

- Energy efficiency

- Low energy usage

- Maintenance requirement

- Low

- Pressure rating

- 0.2 bar (3 PSI)

- Abrasion resistance

- Yes

- Biological compatibility

- No

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Moderate

- Density/particle size

- Variety accepted

- Silo/bin compatibility

- Powdery materials

- Shape

- Semi-convex

- Emission Angle

- Wide

- Material

- Durable Polymer

- Installation Type

- Single or multiple rows

- Mounting Kit

- Rectangular external

- Mounting kit

- Rectangular external

- Construction material

- Durable polymer