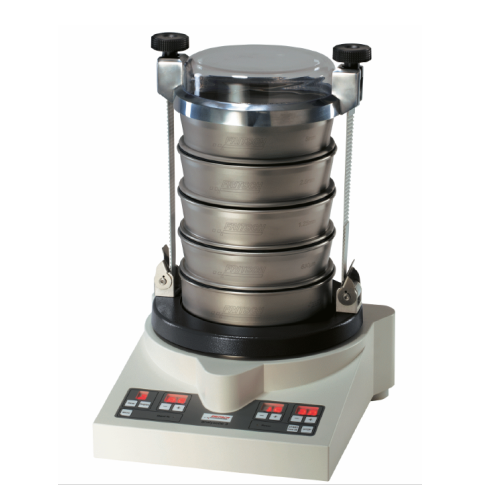

Vibratory sieve shaker for precise particle size distribution

Achieve precise particle size distribution with advanced vibratory sieving technology, ideal for separating and fractioning laboratory samples across various forms, including powders and suspensions, ensuring accurate quality control and efficient processing in your operations.

Precisely Sieves and Separates Laboratory Samples

The Vibratory Sieve Shaker ANALYSETTE 3 PRO from FRITSCH is engineered for precise laboratory sieving tasks, offering robust performance in separating and fractioning various samples. This electromagnetic sieve shaker is distinguished by its automatic amplitude control, ensuring consistent, reproducible results for quality control in pharmaceuticals, food, and mining industries. It operates by oscillating a sieve stack vertically, efficiently processing samples up to 2 kg within a 20 μm to 63 mm range, making it suitable for a diverse array of end-products, including pharmaceutical granules and silica sand. Integration with the AUTOSIEVE software allows for seamless automation and real-time process monitoring through an RS232 interface, enhancing operational efficiency.

The ANALYSETTE 3 PRO supports both dry and wet sieving, coupled with an energy-saving mode to minimize energy consumption. Constructed for durability, it features a warp-free EASYTWIST tensioning system and a modular design that converts it into a Vibratory Micro Mill PULVERISETTE 0 for grinding small quantities. Its materials, available with stainless steel components, ensure chemical compatibility and resistance to wear. The unit complies with ISO 9001 standards, offering configurable settings for testing and validation purposes. Maintenance is streamlined with accessories like the TorqueMaster tensioning system, simplifying sieve stack operations.

Benefits

- Ensures consistency and accuracy in particle size analysis, enhancing quality control outcomes.

- Minimizes operational costs with energy-saving automatic amplitude adjustments.

- Versatile use for a wide range of materials, catering to multiple industries such as pharmaceuticals and food.

- Streamlines lab processes with easy integration and automation via AUTOSIEVE software.

- Durable design reduces maintenance needs and extends equipment lifespan.

- Applications

- Chemicals, Maize kernels, Laboratory samples, Suspensions, Agriculture products, Powders, Flour, Food products, Minerals, Sand, Quality control, Pharmaceuticals

- End products

- Granules for medication, Baking flour, Silica sand for glass manufacturing, Cosmetic powders, Instant drink powders, Starch powders, Seed coatings, Slurry suspensions for coatings, Cornmeal, Mineral powders for ceramics, Pesticide formulations, Protein supplements, Refined sugar crystals

- Steps before

- Sample Preparation, Grinding, Comminution

- Steps after

- Particle Size Analysis, Sieve Evaluation, Sample Analysis, Quality Control

- Input ingredients

- solids, suspensions, sample quantities up to 2 kg, particle size from 20 μm to 63 mm, flour, sand, maize kernels, low density voluminous material

- Output ingredients

- quantitative particle size distribution, fractioned samples, sieved flour, sieved sand, analyzed maize kernels

- Market info

- Fritsch is renowned for manufacturing high-quality, engineered-to-order laboratory instruments for sample preparation and particle sizing in research and industrial laboratories, with a strong reputation for precision, innovation, and reliability.

- Capacity

- Up to 2 kg

- Measurement Range

- 20 μm to 63 mm

- Automation

- Automatic amplitude control

- Power Consumption

- Optimum power consumption

- Amplitude Control

- Guaranteed constant amplitude

- Sieve Stack Usage

- Up to 10 test sieves simultaneously

- Noise Level

- Low-noise

- Working Principle

- Electromagnetic drive oscillations

- Intermittent Mode

- Available for low density material

- RS232 Interface

- Yes

- Sieving Operations

- Up to 5 simultaneous sieving operations

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch

- Cleaning method

- Dry / Wet

- Energy efficiency

- Low-noise operation

- Amplitude control

- Automatic

- Programme selection

- 10 individual sieve programmes

- Intermittent mode

- Available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ISO 9001

- Test instrument monitoring

- Sieve stack configuration

- Up to 10 sieves

- Sieve tensioning system

- Tensioning system TorqueMaster

- Stackable sieve size

- 20 μm to 63 mm

- Modular system

- Convertible to Vibratory Micro Mill

- Material compatibility (wet/dry)

- Dry and wet sieving

- Max sample quantity

- Up to 2 kg

- Control panel type

- Microprocessor control with digital display

- Integration possibilities

- RS232 interface for AUTOSIEVE software connectivity

- Sieve tensioning system

- TorqueMaster for automatic tensioning

- Amplitute control

- AMPCONTROL for constant amplitude

- Programmability

- Stores up to 10 sieve programs