Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes ingredients, reducing your processing time and energy use. Perfect for producing uniform pre- and sourdoughs, it seamlessly integrates into your production line, enhancing the texture and shelf-life of bakery products.

Hydrates and Mixes Dough for Bakery Production

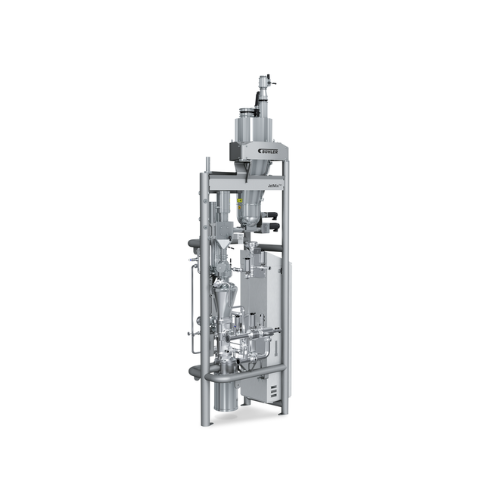

The JetMix Hydration Solutions by Bühler Group offer a cutting-edge approach to dough preparation in industrial bakeries. This system is designed to efficiently hydrate and mix dough ingredients, significantly enhancing the consistency and quality of bakery products. Utilizing state-of-the-art micro-dosing technology, JetMix ensures precise flour hydration through a 360° water jet, resulting in finely mixed pre- and sourdoughs ready for further processing or fermentation.

Targeted for baked goods such as artisan breads, croissants, and whole wheat rolls, JetMix caters to an array of bakery products. It supports continuous operation on an industrial scale, integrating seamlessly into existing production lines with its fully automatic controls. The system’s PLC-controlled interface allows for precise monitoring and process adjustments, optimizing resource efficiency with up to 50% reduced mixing time, subsequently lowering energy consumption.

Constructed entirely in stainless steel, the JetMix system includes options for cleaning-in-place (CIP), streamlining maintenance and ensuring high hygiene standards. Its robust design offers durability and minimal downtime, enabling sustained high-volume production. Bühler provides customization and engineering support, tailoring the system to meet specific production demands, and ensuring integration is both practical and efficient for any bakery setup.

Benefits

- Enhances dough yield without affecting quality, leading to larger volumes and extended shelf life.

- Reduces mixing and kneading time by up to 50%, saving energy and operational costs.

- Fully automated process ensures consistent and reproducible product quality with minimal oversight.

- Stainless steel construction with CIP option offers superior hygiene and easy maintenance.

- Customizable to fit specific production needs, optimizing efficiency and process integration.

- Applications

- Baked goods, Biscuits, Sourdough, Cakes, Bakery products, Predough

- End products

- Multigrain bread loaves, Whole wheat rolls, Layer cakes, Butter cookies, Breadsticks, Specialty sandwich breads, Scone doughs, Artisan breads, Shortbread biscuits, Rye sourdough bread, Doughnuts, Enriched sweet doughs, Croissants, Sponge cakes, Brioche buns

- Steps before

- Grinding, Dough prep, Flour milling

- Steps after

- Fermentation, Baking, Packing, Cooling

- Input ingredients

- flour, water

- Output ingredients

- pre-dough, sourdough, hydrated dough

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Automation

- Fully automatic

- Material

- Stainless steel

- Hydration method

- 360° water jet

- Temperature control

- Precision temperature adjustment

- Kneading time reduction

- Up to 50%

- Mixing time reduction

- Up to 50%

- Cleaning method

- CIP available

- Micro-dosing accuracy

- High accuracy

- Working mechanism

- Continuous hydration

- Integrated steps

- Hydration and mixing

- CIP/SIP

- CIP available

- Batch vs. continuous operation

- Continuous

- Automation level

- Fully automated

- Temperature control

- Automated temperature monitoring

- Energy efficiency

- Less energy consumption

- Cleaning method

- CIP

- Process optimization

- Enhanced dough rheological properties

- Air incorporation control

- 360° water jet hydration

- Abrasion resistance

- Yes

- Cleanability

- Cleaning-in-place (CIP) available

- Corrosive resistance (e.g. acids)

- Constructed in stainless steel

- Biological compatibility

- Suitable for food processing

- CIP option

- Available

- Material construction

- Stainless steel

- Process automation

- Available

- Temperature monitoring and control

- Precise adjustment

- Micro-dosing technology

- Advanced

- Hydration system

- Customized solutions