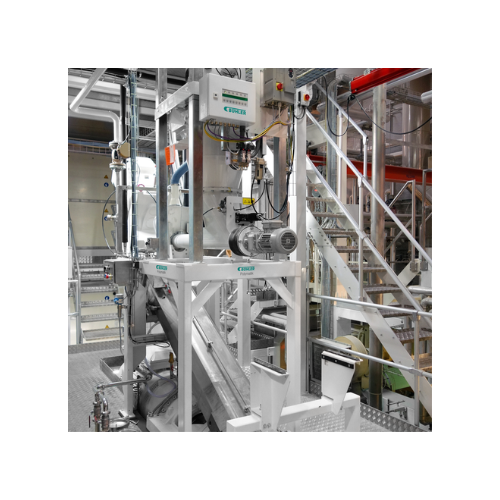

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling both traditional and gluten-free ingredients, enhancing efficiency and ensuring top-tier hygiene in continuous, high-speed operations.

Processes and Shapes Pasta and Food Products

The Polymatik Pasta Press from Bühler is a versatile machine designed for food manufacturers and processors seeking high-quality pasta and food product solutions. It features a co-rotating twin-screw mixer-kneader, facilitating efficient dough formation and shaping through its unique “first-in, first-out” process, minimizing air exposure and oxidation for bright color and superior quality. It handles a wide range of applications, from traditional pasta like spaghetti and penne to gluten-free options and plant-based food products. The system allows rapid recipe changes and minimal downtime due to its quick-stop operations. It integrates easily into production lines with continuous operations and high-speed processing for optimal throughput. Compatible with wheat and gluten-free raw materials, it features steam and hot water injection for processing starch gelatinization required in gluten-free pasta production. Designed to meet stringent food safety standards, the Polymatik offers self-cleaning capabilities, ensuring enhanced hygiene and easy maintenance. The pasta press is available in customizable configurations to suit specific processing needs, with engineering support from Bühler’s technical team.

Benefits

- Enhances production flexibility with quick recipe and format changes.

- Minimizes waste through efficient first-in, first-out processing.

- Ensures product quality with reduced air exposure, preserving color and taste.

- Maintains high hygiene standards with self-cleaning design.

- Supports diverse raw material use, including gluten-free options, enhancing market adaptability.

- Applications

- Snacks, Bakery, Grain, Dairy, Pulses, Spices, Aqua feed, Animal feed, Alternative proteins, Pasta, Pet food, Nuts, Food ingredients, Rice, Dried fruits, Oilseeds, Confectionery, Gluten-free products, Vegetables, Wheat products

- End products

- Spaghetti, Energy bars, Breadsticks, Sesame seeds, Chocolate-covered nuts, Sun-dried tomatoes, Basmati rice, Fish pellets, Pasta dough, Chili powder, Gluten-free fusilli, Roasted almonds, Macaroni, Plant-based burger patties, Lentil pasta, Dog treats, Fusilli, Wheat lasagna sheets, Whole grain pasta, Gluten-free penne, Cattle feed blocks, Penne, Milk protein pasta, Vegetarian protein sausages

- Steps before

- Mixing, Kneading, Raw material preparation, Steam injection

- Steps after

- Shaping, Drying, Cooking, Packaging

- Input ingredients

- durum wheat, common wheat, grain, gluten-free ingredients, corn, rice, pulses, quinoa

- Output ingredients

- pasta, gluten-free pasta

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Mixing time

- About 20 seconds

- Material variety

- Wheat, gluten-free ingredients (corn, rice, pulses, quinoa)

- Process type

- First-in, first-out

- Automation

- Push-button start/stop

- Raw material processing

- Durum wheat, common wheat, gluten-free

- Dough formation

- Controlled and repeatable conditions

- Screw type

- Co-rotating twin-screw

- Steam and water injection

- Direct steam and hot water

- Color preservation

- Bright and golden color with limited oxidation

- System closure

- Closed system for optimal hygiene

- Safety standards

- Meets max hygiene and safety standards

- Working mechanism

- Co-rotating twin-screw mixer-kneader

- Automation level

- Automatic with PLC/SCADA

- Batch vs. continuous operation

- Batch / Inline continuous

- Cleaning method

- Self-cleaning system

- Integration of raw material mixing

- Integrated mixing surface

- Process flexibility

- Various raw materials including gluten-free

- Downtime

- Minimized with "first-in, first-out" operations

- Changeover time

- Fast recipe changes

- Wheat

- Common, Durum

- Gluten-Free Ingredients

- Corn, Rice, Pulses, Quinoa

- Grains

- General grains

- Raw Material Flexibility

- High

- Homogeneous Dough Formation

- All compatible materials

- Machine footprint

- Compact design

- Feed/discharge method

- First-in, first-out process

- Control panel type

- Touch screen/interface

- Compact footprint

- Minimal space usage

- Design

- Closed system for hygiene

- Mixing technology

- Co-rotating twin-screw mixer-kneader

- Co-rotating twin-screw mixer-kneader

- Flexible

- Recipe changes

- Fast, push-button operation

- Process type

- First-in, first-out

- Raw material flexibility

- Wheat, gluten-free

- Steam and hot water injection

- Available

- Batch size

- Variable

- Controlled and repeatable conditions

- Yes

- Main screw design

- Shapes dough through pasta die