Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to efficiently handle ready meals, salads, jars, and cans, ensuring seamless integration and streamlined operations for increased productivity.

Packs and Cartons Ready Meals and Snacks

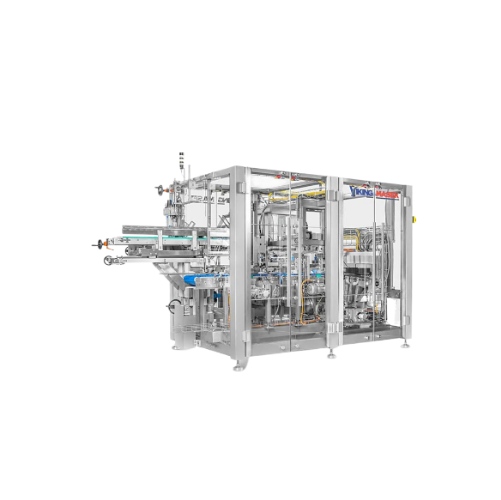

The CAM-S Sleeve Cartoner from Viking Masek is a versatile cartoning machine designed for food and beverage manufacturers looking to optimize packing efficiency for products ranging from frozen lasagna to potato chips. Utilizing a robust wrap-around process, it accommodates varied product shapes with servo-driven precision, ensuring seamless high-speed operations at up to 50 cartons per minute. The stainless steel construction supports long-term durability, while easy changeover features and remote control capabilities offer flexible production line integration. Select Siemens or Allen Bradley controls augment automation, ensuring consistent performance and minimizing downtime. Optional extended carton magazines and specialized infeed conveyors provide tailored solutions to meet specific packaging requirements, while the rugged design ensures high standards of reliability in diverse production environments.

Benefits

- Streamlines packaging efficiency for a diverse range of products.

- Enhances production flexibility with quick and easy changeovers.

- Ensures continuous operation and minimizes downtime with reliable servo-driven controls.

- Durable stainless steel construction prolongs machine lifespan and reduces maintenance needs.

- Versatile integration capabilities allow seamless addition to existing production lines.

- Applications

- Ready meals, Cereal, Snacks, Salads, Jars, Nuts, Cans

- End products

- Cornflakes, Frozen lasagna, Potato chips, Caesar salad kits, Mason jar preserves, Aluminum soda cans, Almonds

- Steps before

- Product preparation, Sorting, Feeding, Infeed setup

- Steps after

- Carton sealing, Outfeed conveyor processing, Inspection, Damaged carton rejection

- Input ingredients

- ready meals, salads, jars, cans, cereal, nuts, snacks

- Output ingredients

- sleeve cartons

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 50 cpm

- Bag Size

- Min 150 x 155 x 40 mm

- Bag Size

- Max 200 x 230 x 50 mm

- Weight

- 1, 500 kg

- Power Supply

- 5 kVA

- Construction Material

- Rugged stainless steel

- Drive System

- Servo drive

- Control System

- Siemens or Allen Bradley controls

- Process

- Wrap-around process

- Automation level

- PLC / Servo drive

- Batch vs. continuous operation

- Continuous Motion

- Changeover time

- Easy change-over

- Cleaning method

- Accessibility for manual cleaning

- Control system

- Siemens or Allen Bradley

- Damaged product handling

- Damaged carton rejection

- Outfeed options

- Various styles of outfeed conveyors

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- Min 150 x 155 x 40 mm, Max 200 x 230 x 50 mm

- Product type

- Ready meals, salads, jars, cans

- Material compatibility

- Stainless steel construction

- Drive type

- Servo drive

- Control system

- Siemens or Allen Bradley controls

- Operational speed

- Up to 50 cpm

- Carton style

- Sleeve cartoning

- Customization

- Custom infeed conveyors

- Discharge method

- Wrap-around process

- Control panel type

- Servo drive, Siemens or Allen Bradley controls

- Carton size

- Min 150 x 155 x 40 mm

- Carton size

- Max 200 x 230 x 50 mm

- Weight

- 1, 500 kg

- Construction Material

- Stainless steel

- Changeover features

- Easy change-over

- Accessibility

- Excellent accessibility

- Control panel type

- Siemens / Allen Bradley controls

- Drive system

- Servo drive

- Outfeed conveyor styles

- Various

- Carton magazine type

- Extended carton magazine

- Remote control

- Available

- Infeed conveyor design

- Designed for product shape

- Special electrics and voltages

- Optional