Ice cream decoration depositing solution

Transform your ice cream line with precise decoration capabilities, enhancing product appeal and variety without increasing operational complexity or costs.

Deposits and Decorates Ice Cream with Precision

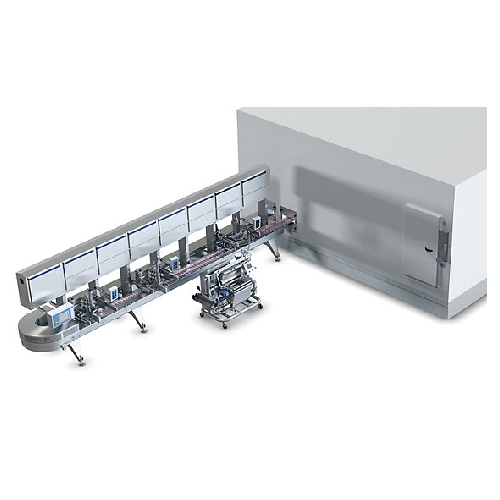

The Tetra Pak Decoration Depositing Unit offers innovative solutions for ice cream production lines with unparalleled precision and flexibility in decoration applications. This unit integrates seamlessly into extrusion operations, allowing manufacturers to create intricate designs, such as layered, patterned, and flavored ice creams, directly onto products like caramel swirl and stracciatella ice creams. Utilizing high-speed automated processes, the unit deposits decoration materials with a 48-hole nozzle system, ensuring high repeatability and uniformity across batches, while minimizing waste. Its advanced software enables detailed product customization, from design creation to execution, supporting an infinite variety of novelties without needing additional equipment. Designed for continuous, efficient operations, this unit offers optimized material use, translating into cost savings and enhanced production capacity. The Decoration Depositing Unit aligns with rigorous industry standards, promising quality and reliability for food industry professionals looking to push their creative boundaries in ice cream manufacturing.

Benefits

- Diversifies product portfolio with endless design possibilities, boosting market competitiveness.

- Minimizes material waste with precise depositing and integrated product sensing.

- Reduces operational costs through efficient material usage and high design repeatability.

- Simplifies production transitions with flexible design changes without the need for additional equipment.

- Enhances product consistency and quality, ensuring each item meets customer expectations.

- Applications

- Flavored ice cream, Layered ice cream, Patterned ice cream, Ice cream, Ice cream decorations

- End products

- Custom-designed ice cream novelties, Multi-layered ice cream bars, Fruit-patterned ice cream pops, Caramel swirl ice cream, Chocolate ripple ice cream, Vanilla bean ice cream with chocolate layers, Mint chocolate chip ice cream, Stracciatella ice cream

- Steps before

- Mixing ingredients, Formulation of ice cream base, Extrusion setup

- Steps after

- Freezing, Hardening, Packaging

- Input ingredients

- caramel, ripple, chocolate compound, different flavours

- Output ingredients

- decorated ice cream, elaborate decorations, pattern prints, full coverage, layered decorations

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Design precision

- High precision with 48-hole nozzles

- Decoration repeatability

- High repeatability

- Material compatability

- Caramel, ripple, chocolate compound

- Design change flexibility

- Infinite design changes possible

- Software integration

- Design Studio software for pattern creation

- Automation

- Pauses when no product detected

- Cost efficiency

- Low operational cost

- Operational control

- Independent design control

- Sensor integration

- Pauses decoration if product is missing

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick design switch

- CIP/SIP

- CIP compatible

- Integration type

- Extrusion line worktable

- Decorating method

- Advanced depositing technology

- Layering capability

- Multiple layers with different flavors

- Decoration Type

- Full coverage, layers, pattern prints

- Control panel type

- Touchscreen interface

- Compact footprint

- Mounted as workstation

- Nozzle configuration

- 48-hole nozzles

- Discharge method

- Print on surface

- Input method

- Caramel, ripple, chocolate compound

- Control panel type

- Design Studio software

- Integration possibilities

- Mounted as workstation on extrusion line