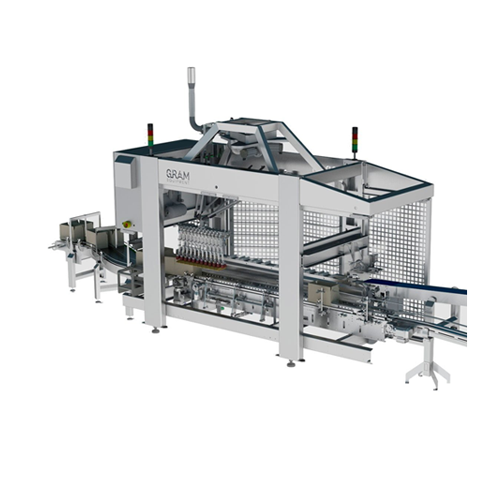

High capacity molding line for ice cream sticks

Optimize your frozen dessert production with a high-capacity system that integrates molding, freezing, and precise stick insertion, ensuring consistent quality and efficiency.

Molds and Extracts Ice Cream Stick Products

The RIA 8 from Gram Equipment is a high-capacity ice cream molding machine tailored for large-scale production of stick-based frozen desserts. This self-contained unit integrates a hot and cold brine system with minimal maintenance requirements, featuring servo-driven operations for precise and efficient processes. Capable of producing up to 27,000 pieces per hour, the RIA 8 accommodates a wide range of applications, including ice cream bars, fruit popsicles, and gelato sticks.

Leveraging its internal coil evaporator, the machine ensures optimal brine contact, thereby enhancing energy efficiency and freezing performance. The RIA 8’s modular design empowers seamless integration into existing production lines, offering flexibility through quick changeovers and recipe-based setups. Its automated stick insertion system and servo-controlled extraction provide consistent product quality while reducing the risk of downtime.

The RIA 8 is constructed from durable materials, with double-sealed mold tables that prevent leaks and improve product uniformity. Optional features, such as CO2 cooling and external evaporators, allow further customization to meet specific operational needs. This molding line is ideal for ice cream manufacturers and frozen dessert producers seeking robust, continuous, and efficient solutions for their processing lines.

Benefits

- Increases production efficiency with a capacity of up to 27,000 pieces per hour.

- Lowers energy costs through optimized brine flow and servo-driven operations.

- Minimizes maintenance with a durable design that requires cleaning only every 10 years.

- Enhances product quality with precise molding and extraction processes.

- Facilitates quick product changeovers, reducing downtime and improving flexibility in production.

- Applications

- Water ice, Frozen desserts, Ice cream, Novelty molded stick products

- End products

- Fruit popsicles, Ice cream sandwiches, Gelato sticks, Ice cream bars, Sherbet sticks

- Steps before

- Mixing ingredients, Heat treatment, Flavor addition, Preparation of brine solution

- Steps after

- Product cooling, Packaging, Quality inspection, Storage

- Input ingredients

- novelty molded stick products, ice cream mix, water ice mix, custom sticks, brine

- Output ingredients

- molded stick products, ice cream, water ice, brine-treated products

- Market info

- Gram Equipment is known for manufacturing innovative industrial ETO equipment for the ice cream industry, offering advanced technology solutions and a strong reputation for high-quality, reliable machinery tailored to customer needs.

- Capacity

- Up to 27, 000 pcs/h

- Brine System

- Energy-efficient hot, cold brine system

- Energy Efficiency

- Servo drives throughout the machine

- Brine Maintenance

- Minimum maintenance required, 10 years before cleaning

- Cooling Option

- CO2 cooling as an option

- Brine Temperature

- Low hot brine temperature

- Brine Pump

- Frequency controlled pump for hot brine

- Evaporator Type

- Internal coil evaporator

- Automation

- Automatic rotary machines

- Moldtable Handling

- Divided into sections for easy handling and change-over

- Stick Handling

- Automatic with feeding from a cardboard box

- Extractor Type

- Servo driven main chain and extraction

- Mold Release

- Individual mold release option

- Dipping Possibilities

- Multi-dipping possibilities

- Working Mechanism

- Rotary machine with servo-driven components

- Integrated Steps

- Molding, brine treatment, stick insertion, extraction

- Automation Level

- Fully automated with servo drives

- Batch vs. Continuous Operation

- Continuous

- Changeover Time

- Fast, due to servo drives

- Energy Efficiency

- Highly efficient with low energy consumption

- Cleaning Method

- Requires minimal maintenance

- Abrasion resistance

- High abrasion resistance materials used

- Corrosive resistance (e.g. acids)

- Materials resistant to brine and low temperatures

- Biological compatibility

- Suitable for food contact (ice cream production)

- Density/particle size

- Handles various densities of ice cream and water ice

- Cleanability

- Designed for easy maintenance and cleaning, 10 years before cleaning required

- Product type

- Ice cream, water ice, novelty molded stick products

- Tank shape

- Internal coil evaporator

- Moldtable

- Double support of mold plates

- Feed/discharge method

- Automatic, Servo driven main chain

- Control panel type

- Servo driven

- Integration possibilities

- Recipe based setup

- Handling options

- Automatic / Semiautomatic stick inserter

- Cooling options

- CO2 cooling

- Evaporator type

- Internal coil / External option

- Stick handling

- Screw stacker / Finger stacker