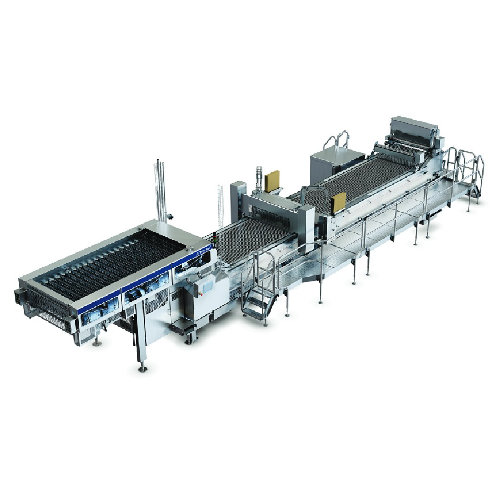

High-capacity ice cream stick production line

Maximize production efficiency with a high-speed, continuous ice cream molding system that expertly handles complex product varieties, ensuring consistent quality and precise stick placement for every batch.

Processes and Moulds Ice Cream Sticks Efficiently

The Tetra Pak® Linear Moulder 1500 A2 is engineered for ice cream manufacturers requiring a versatile solution to produce a wide range of ice cream and sherbet stick products. This equipment excels in high-speed and continuous production, integrating seamlessly into existing lines. Its flexible, modular system allows for various filling techniques, supporting diverse product profiles, from chocolate-dipped ice cream sticks to fruit-juice popsicles. With a throughput of up to 43,200 products per hour, it optimizes productivity while maintaining high product quality through a servo-driven, precise moulding process. The system’s brine cooling and defrost cycle ensure consistent temperature control, enhancing energy efficiency and product consistency. Built with automatic stick insertion and advanced utility connections, it reduces manual intervention and water usage by 50%, thanks to an innovative multi-tank cleaning system. Constructed with robust materials for hygiene and durability, it offers optional features like dry coating and volumetric filling, supported by comprehensive engineering assistance for customization.

Benefits

- Enhances production efficiency by processing up to 43,200 ice cream sticks per hour.

- Minimizes water usage by 50% with a smart multi-tank cleaning system.

- Ensures consistent product quality with precise servo-driven moulding and controlled brine cooling.

- Reduces manual intervention through automatic stick insertion and product removal features.

- Increases versatility with multiple filling options, allowing for a wide range of product varieties.

- Applications

- Sherbet, Water ice, Ice cream, Fruit-juice sticks, Moulded ice products

- End products

- Mixed berry fruit-juice sticks, Chocolate-dipped ice cream sticks, Multicolored sherbet bars, Lemon water ice sticks, Vanilla ice cream with inclusions, Raspberry water ice bars, Ice cream bars, Cream-filled ice pops, Orange flavored sherbet sticks, Strawberry fruit-juice popsicles

- Steps before

- Filling ice cream mix, Inserting wooden sticks, Freezing product in cold brine bath

- Steps after

- Defrosting with warm water spray, Coating with chocolate, Dry coating, Lay-down into wrapping machine

- Input ingredients

- ice cream mix, water ice, sherbet, fruit-juice, brine, wooden sticks, chocolate, dry ingredients, volumetric fillers

- Output ingredients

- ice cream sticks, moulded ice products, sherbet sticks, water ice sticks, fruit-juice sticks, coated ice cream products

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 43, 200 ice cream sticks/hr

- Speed

- 30 strokes/minute

- Filling method

- Volumetric top, bottom, time elapse top, pencil filler and back suction

- Cooling temperature

- Brine at -40°C

- Mould cleaning system

- Multi-tank flush system

- Cooling system

- Brine cooling system with efficient heat transfer

- Automation

- Servo-driven

- Filling adaptability

- Adaptable to varied filling methods

- Water consumption

- Reduced by approximately 50%

- Production speed

- 30 strokes/minute

- Automation level

- Servo-driven

- Batch vs. continuous operation

- Continuous

- Cooling system

- Efficient brine cooling

- Filling flexibility

- Adaptable filling methods

- Water consumption

- Minimal during cleaning

- Cleaning method

- Automatic product removal

- Hygiene level

- Robust and hygienic design

- Nozzle plate solution

- Creates turbulence for efficient cooling

- Modular design

- Flexible for various product types

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- High capacity, modular design

- Cooling System

- Brine cooling system

- Mould drive system

- Servo-driven, robust chain system

- Nozzle plate

- Unique design for efficient brine flow

- Automatic stick inserter

- Double magazine with reversing in-feed belt

- Filling options

- Volumetric top and bottom fillers, time elapse top filler, pencil filler

- Cleaning system

- Modular, minimizes water consumption

- Control panel type

- Servo-driven control, PLC integrated

- Mould cleaning system

- Flexible, modular, minimum water consumption

- Filling method

- Volumetric top/bottom filler, time elapse top filler, pencil filler, back suction

- Product adaptation

- Pre-set recipes in automation system

- Automatic stick inserter options

- Double magazine, reversing in-feed belt

- Nozzle plate solution

- Unique design for efficient cooling

- Dry coater

- New generation, on-the-fly emptying

- Combi Top Filler

- Pneumatic or servo-driven, multiple colors, adjustable volume

- Brine buffer tank

- Brine concentration maintenance