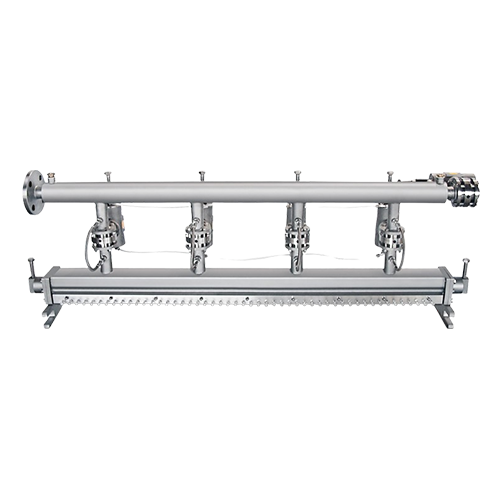

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in chocolate and fruit mass production with advanced extrusion and co-extrusion technology, providing seamless integration into your high-speed confectionery line.

Extrudes and Co-Extrudes Chocolate Ropes

The Manifold Extruder from Sollich is an expertly engineered system designed for precise extruding and co-extruding of chocolate and confectionery products. Utilizing continuous extrusion technology, it efficiently processes ropes of filled and solid confections with consistent weight and shape accuracy. This system is a staple in high-volume, high-speed confectionery production lines, producing chocolate truffles, granola bars, and chocolate decorations. With a working width ranging from 420 to 1500 mm, it integrates seamlessly with upstream and downstream processes for cooling and cutting. Designed with easy cleaning and rapid format change in mind, it reduces downtime and enhances operational efficiency. The Manifold Extruder supports various confectionery applications, ensuring compliance with industry standards while offering customizable configurations to meet specific production needs.

Benefits

- Ensures precise product shaping and weight accuracy, enhancing final product quality.

- Enables flexible production with quick format changes, reducing downtime.

- Integrates easily with existing lines, optimizing space and process efficiency.

- Supports a broad range of confectionery applications, increasing product diversity.

- Facilitates easy cleaning, reducing maintenance time and contamination risk.

- Applications

- Biscuits, Brittle bars, Snacks, Pralines, Fruit bars, Chocolate products, Cereal bars, Sweets, Candy bars, Ice cream, Chocolate decorations, Protein bars

- End products

- Wafer biscuits, Chocolate truffles, Muesli bars, Granola bars, Nougat candy bars, Chocolate sprinkles, Ice cream inclusions, Chocolate-coated pralines, Chocolate-covered nuts, Chocolate shells

- Steps before

- Mixing, Emulsification, Flavour and Colour Dosing

- Steps after

- Cooling, Cross-Cutting, Guillotining, Packing, Decorating

- Input ingredients

- chocolate mass, fruit mass, mint filling, fruit filling, nut cream filling

- Output ingredients

- chocolate ropes, fruit ropes, filled ropes

- Market info

- Sollich is known for manufacturing engineered-to-order equipment for the confectionery industry, particularly chocolate processing and enrobing machines. They have a strong reputation for innovation, quality, and tailored solutions to meet specific customer requirements.

- Working width

- 420 - 1500 mm

- Accuracy

- Precise weight and shape

- Quick format change

- Yes

- Cooling time

- Short

- Working mechanism

- Extrusion and co-extrusion

- Integrated steps

- Cooling and cross-cutting

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Changeover time

- Quick format change

- Cleaning method

- Easy cleaning

- Working width

- 420 - 1500 mm

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies, 420 - 1500 mm working width

- Control panel type

- Advanced controls with easy changeover

- Discharge method

- Guillotine systems for precise cutting

- Compact footprint

- Designed for space efficiency

- Quick format change

- Yes

- Working width

- 420 - 1500 mm

- Co-extruder options

- Mint, fruit, or nut cream filling