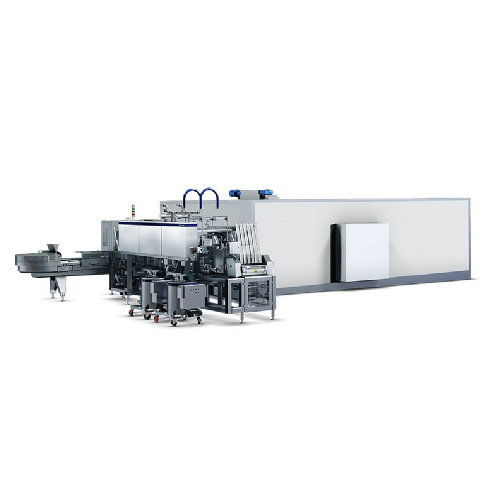

Ice cream cone production system

Streamline your ice cream production and enhance product quality with a continuous system that efficiently extrudes, shapes, fills, and hardens diverse frozen treats to meet high-demand requirements.

Extrudes, Shapes, and Hardens Ice Cream Cones

The Tetra Pak Extrusion Tunnel M1.3 is engineered for high-speed ice cream production, offering unparalleled efficiency in extrusion, shaping, filling, and hardening processes. Optimized to produce up to 18,000 cones per hour, it supports a variety of ice cream formats, including vanilla, chocolate-dipped, and multilayered cones, as well as customized frozen desserts. Designed for continuous operation, this system integrates seamlessly into existing production lines with automated pick-and-place and cone off-loading systems, reducing manual handling and operational costs. Its hygienic design ensures consistent product quality and fast cleaning, while optional servo motor controls enable precise, repeatable processes. Constructed for durability and reliability, the Tetra Pak Extrusion Tunnel M1.3 is an ideal choice for large-scale ice cream manufacturers and dairy producers seeking to enhance product quality and throughput.

Benefits

- Enhances production efficiency with automated shaping and filling processes.

- Minimizes product waste and rejects with gentle handling and precise operations.

- Increases production capacity to 18,000 cones per hour, accommodating high-demand scenarios.

- Reduces labor and injury risks with automated offloading systems.

- Ensures consistent quality output through repeatable and controlled processes.

- Applications

- Frozen desserts, Ice cream products, Ice cream cones

- End products

- Ball-top ice cream cones, Vanilla ice cream cones, Custom-flavored frozen desserts, Decorated ice cream bars, Multilayered ice cream bars, Strawberry swirl cones, Chocolate-dipped cones

- Steps before

- Mixing, Homogenization, Aging, Freezing

- Steps after

- Packaging, Labeling, Storage, Distribution

- Input ingredients

- ice cream mix, cone sleeves, decorations, toppings

- Output ingredients

- ice cream cones, decorated ice cream cones, hardened ice cream cones

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- Up to 18, 000 cones per hour

- Cone Diameter

- 45 to 75 mm

- Automation

- Automated offloading

- Filling Method

- Inline

- Hygienic Design

- Yes

- Process Type

- Tray tunnel system

- Hardening Method

- Vertical hardening

- Product Customization

- Wide range of filling and decoration options

- Cooling Medium

- Evaporator cooled air

- Air Circulation

- Fans for maximizing hardening effect

- Working mechanism

- Tray tunnel system with continuous product plate conveyor loop

- Integrated Steps

- Extrusion, shaping, filling, hardening, automated offloading

- Automation level

- PLC-controlled

- Changeover time

- Fast and flexible

- CIP/SIP

- CIP for fast and safe cleaning

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- Optimized for reduced energy consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cooling method

- Tray tunnel system

- Machine footprint

- Compact

- Tray tunnel system

- Continuous product plate conveyor loop system

- Tray system type

- Horizontal and vertical hardening

- Cone handling capability

- 45 to 75 mm diameter

- Discharge method

- Automated cone off-loading

- Capacity

- Up to 18, 000 cones per hour

- Automation level

- Switch from rotary to inline filling

- Transfer system

- Pick-and-place transfer system

- Offloading type

- Automated offloading