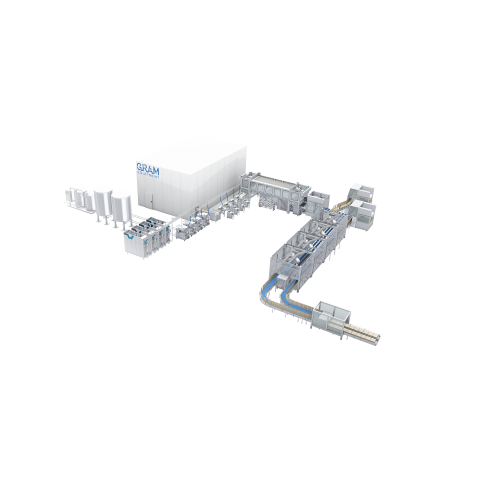

High-speed ice cream extrusion line

Achieve precise shapes and textures in your frozen treats with advanced extrusion solutions that maximize efficiency while maintaining product integrity, from traditional ice cream bars to innovative dairy-free options.

Produces and Hardens Ice Cream and Dairy-Free Products

The BT extrusion lines from Gram Equipment are engineered for high-speed production of ice cream and dairy-free products, offering flexibility and precision in processing sticks, bars, cones, and more. Utilizing a well-proven tunnel design, these lines optimize airflow for efficient hardening. Applications include ice cream sticks, sandwiches, and cones, essential for food and dairy industries. With a capacity of up to 42,000 pieces per hour, these lines ensure continuous operation with advanced electronic synchronization and integrated performance monitoring. The equipment features an energy-saving, sequential defrost system with three evaporators to maintain consistent temperatures and product quality. Maintenance is streamlined with servo stick inserters, anti-freeze chain systems, and an easily accessible worktable design. Hygiene standards are exceptional, equipped with ProFlow control and an instant wash tray cleaning system. Gram Equipment provides additional customization and engineering support to meet specific production needs.

Benefits

- Increases product output with a capacity of up to 42,000 pieces per hour.

- Enhances product quality and consistency through optimized airflow and precise electronic synchronization.

- Minimizes energy consumption with a sequential defrost system maintaining constant temperatures.

- Simplifies maintenance and cleaning, reducing downtime with anti-freeze chain systems and instant wash capabilities.

- Ensures flexible product versatility, supporting a range of traditional and dairy-free ice cream products.

- Applications

- Dairy-free ice cream, Frozen snacks, Confectionery, Frozen treats, Desserts, Ice cream

- End products

- Ice cream sticks, Ball top cones, Ice cream bars, Dairy-free ice cream sticks, Dairy-free ice cream bars, Ice cream logs, Ice cream sandwiches, Ice cream cakes

- Steps before

- Mixing ingredients, Forming ice cream base

- Steps after

- Hardening, Wrapping, Cartonizing, Packing

- Input ingredients

- ice cream mix, flavor inclusions, dairy-free ingredients, bulk ice cream

- Output ingredients

- ice cream sticks, ice cream sandwiches, ball top cones, ice cream bars, ice cream logs, ice cream cakes, hardened cones, hardened cups, hardened bulks

- Market info

- Gram Equipment is known for manufacturing innovative industrial ETO equipment for the ice cream industry, offering advanced technology solutions and a strong reputation for high-quality, reliable machinery tailored to customer needs.

- Capacity

- up to 42, 000 pcs/h

- Tunnel System

- Sequential defrost with three evaporators

- Airflow Control

- ProFlow control of airflow in tunnel

- Cleaning Method

- Tray cleaning without defrosting “instant wash”

- Stick Inserters

- Four stick inserters operated by a single person

- Stick Inserter Precision

- Servo stick inserters ensure highest precision

- Motor System

- Sequenced motor start-up

- Multiple drive motors

- Chain System

- Anti-freeze chain, max 70 meter chain between drives

- Automation

- Advanced electronic synchronization, integrated performance monitoring

- Product Versatility

- Full product versatility and set-up flexibility

- Hygienic Standards

- Exceptional hygienic standards

- Airflow control

- ProFlow control of airflow in tunnel

- Automation level

- Advanced electronic synchronization

- Cleaning method

- "Instant wash" tray cleaning without defrosting

- Changeover time

- Format change optimized

- CIP/SIP

- Highly effective cleaning systems

- Tunnel hardening efficiency

- Optimized airflow in tunnel

- Product versatility

- Full product versatility

- Integrated performance monitoring

- Yes

- Automation level

- Servo stick inserters

- Container size and shape

- Sticks, sandwiches, cones, bars, logs, cakes, cones, cups

- Machine footprint

- Compact

- Tunnel shape and size

- Optimized for airflow

- Tray cleaning method

- Instant wash

- Control panel type

- Advanced electronic synchronization

- Chain system layout

- Anti-freeze, multiple drive motors

- Extruder layout

- Four stick inserters, servo-controlled

- Control panel type

- Advanced HMI / PLC Integration

- Integration possibilities

- Seamless with Existing Systems

- Laser view positioning

- Product in position guidance

- Tunnel airflow control

- ProFlow control system

- Cleaning options

- "Instant wash" tray cleaning

- Extruder flexibility

- Multiple stick insertions

- Drive motor placement

- Top deck for easy maintenance

- Antifreeze chain

- Easy cleaning and maintenance

- Stick insertion precision

- Servo stick inserters