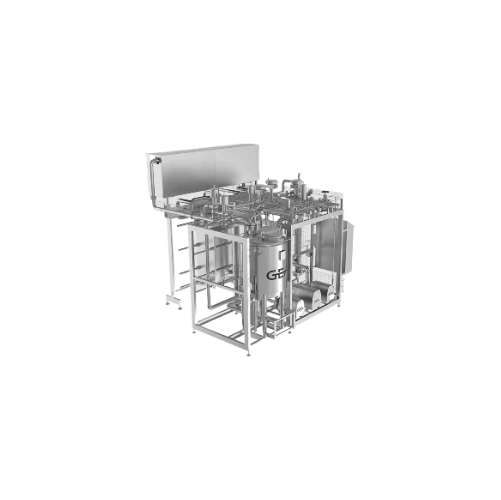

Pasteurizer system for dairy applications

Achieve optimal pasteurization with precise temperature control and energy-efficient recovery systems, ensuring high product quality across diverse dairy applications while reducing operational costs and environmental impact.

Processes Dairy Products with Heat Recovery

The GEA Pasteurizer Systems are designed to meet the rigorous demands of dairy producers and food processors. These systems stand out due to their robust heat recovery capabilities, achieving over 90% energy efficiency for milk products. Their architecture supports a range of operations, processing up to 50,000 liters per hour, ideal for products such as whole milk, cream, yogurt, and cheese. The pasteurizers utilize precise temperature control between 72°C to 85°C, ensuring consistent quality across various batches.

Automation and integration are at the core, with PLC controls enabling seamless remote monitoring and adjustments, thus enhancing operational efficiency. The systems are customizable, fitting into diverse plant layouts, and are equipped to handle various dairy derivatives, from Greek yogurt to premium ice cream. Optional integration of heat pump technology can further minimize reliance on fossil fuels, reducing the facility’s carbon footprint. Built for durability, the equipment’s stainless steel construction ensures compatibility with food-grade processes, while compliance with international quality standards guarantees product safety. The built-in Clean-In-Place (CIP) system streamlines maintenance, allowing for quick and effective cleaning between production runs. Whether upgrading an existing line or setting up a new one, GEA offers engineering support to tailor the pasteurizer systems to specific process requirements, ensuring optimal performance and yield.

Benefits

- Maximizes energy efficiency with over 90% heat recovery, lowering operational costs.

- Enhances product quality through precise temperature control, ensuring consistent pasteurization.

- Reduces carbon footprint by potentially eliminating the need for fossil fuel boilers.

- Improves production flexibility, allowing rapid switching between different dairy products.

- Simplifies maintenance and cleaning with built-in CIP system, minimizing downtime.

- Applications

- Cream, Milk products, Sour milk products, Cheese, Ice cream mixes, Yoghurt, Whey applications, Dairy

- End products

- Skimmed milk, Kefir, Whey protein isolate, Greek yoghurt, Soft serve ice cream, Evaporated milk, Mozzarella cheese, Heavy cream, Buttermilk, Cheddar cheese, Whipping cream, Premium ice cream, Flavored yoghurt, Whole milk, Whey protein concentrate

- Steps before

- Milk collection, Cream separation, Standardization, Homogenization

- Steps after

- Cooling, Filling, Packaging, Storage

- Input ingredients

- milk, cream, milk-mix drinks, yoghurt, cheese, sour milk products, ice cream mixes, whey applications

- Output ingredients

- pasteurized milk, pasteurized cream, pasteurized milk-mix drinks, pasteurized yoghurt, pasteurized cheese, pasteurized sour milk products, pasteurized ice cream mixes, pasteurized whey applications

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 5, 000–50, 000 l/h for milk

- Capacity

- 2, 500–10, 000 l/h for cream

- Heating temperature

- 72–85 °C

- Heat recovery

- >90% for milk and milk-mix products

- Heat recovery

- >85% for cream

- Pasteurization profile

- Customizable

- Automation

- User-friendly control

- Heating method

- Heat pump technology

- Energy management

- 100% pasteurization energy via heat pumps possible

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Heat recovery rate

- >90% for milk, >85% for cream

- Temperature range

- 72–85 °C

- Capacity

- 5, 000–50, 000 l/h for milk, 2, 500–10, 000 l/h for cream

- Heat pump integration option

- Yes

- Product switching capability

- Multiple products per day

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable

- Tank size

- 5, 000–50, 000 L/h for milk

- Tank size

- 2, 500–10, 000 L/h for cream

- Heating temperature range

- 72–85 °C

- Heat recovery level

- >90% for milk products

- Heat recovery level

- >85% for cream

- Integration options

- Preassembled / Custom-built

- Holding time variable

- Dependent on end product

- Control panel type

- User-friendly interface

- Customization for end product

- Consumer milk, milk-mix drinks, cream, yoghurt, cheese, sour milk products, ice cream mixes, whey applications

- Integration possibilities

- Heat pump units integration

- Plant layout adaptability

- Custom configurations to fit physical layout

- Pasteurization profile customization

- Specific pasteurization profile tailoring